Permaglide Plain Bearing

Price 500 INR/ Piece

Permaglide Plain Bearing Specification

- Precision Rating

- P0

- Retainer

- No

- Lubrication Type

- Dry/Lubricated

- Inside Diameter

- 10 mm

- Thickness

- 16 mm

- Bearing Type

- Plain Bearing

- Material

- Permaglide Metal-Polymer Composite

- Structure

- Plain

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 10 mm

- Outside Diameter

- 12 mm

- Load Capacity

- High

- Compliance

- RoHS Compliant

- Dynamic Load Capacity

- Up to 140 N/mm²

- Static Load Capacity

- Up to 250 N/mm²

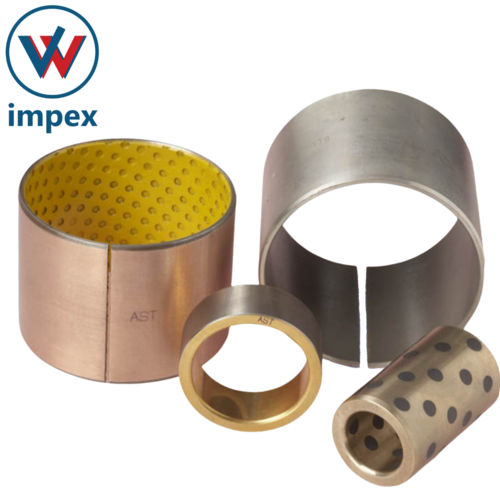

- Color

- Brown / Metallic

- Application

- Hydraulic Cylinders, Agricultural Machinery, Automobiles, Construction Machinery

- Corrosion Resistance

- Yes

- Operating Temperature Range

- -195°C to +280°C

- Surface Finish

- Precision-Ground

- Type

- Self-Lubricating Bush

About Permaglide Plain Bearing

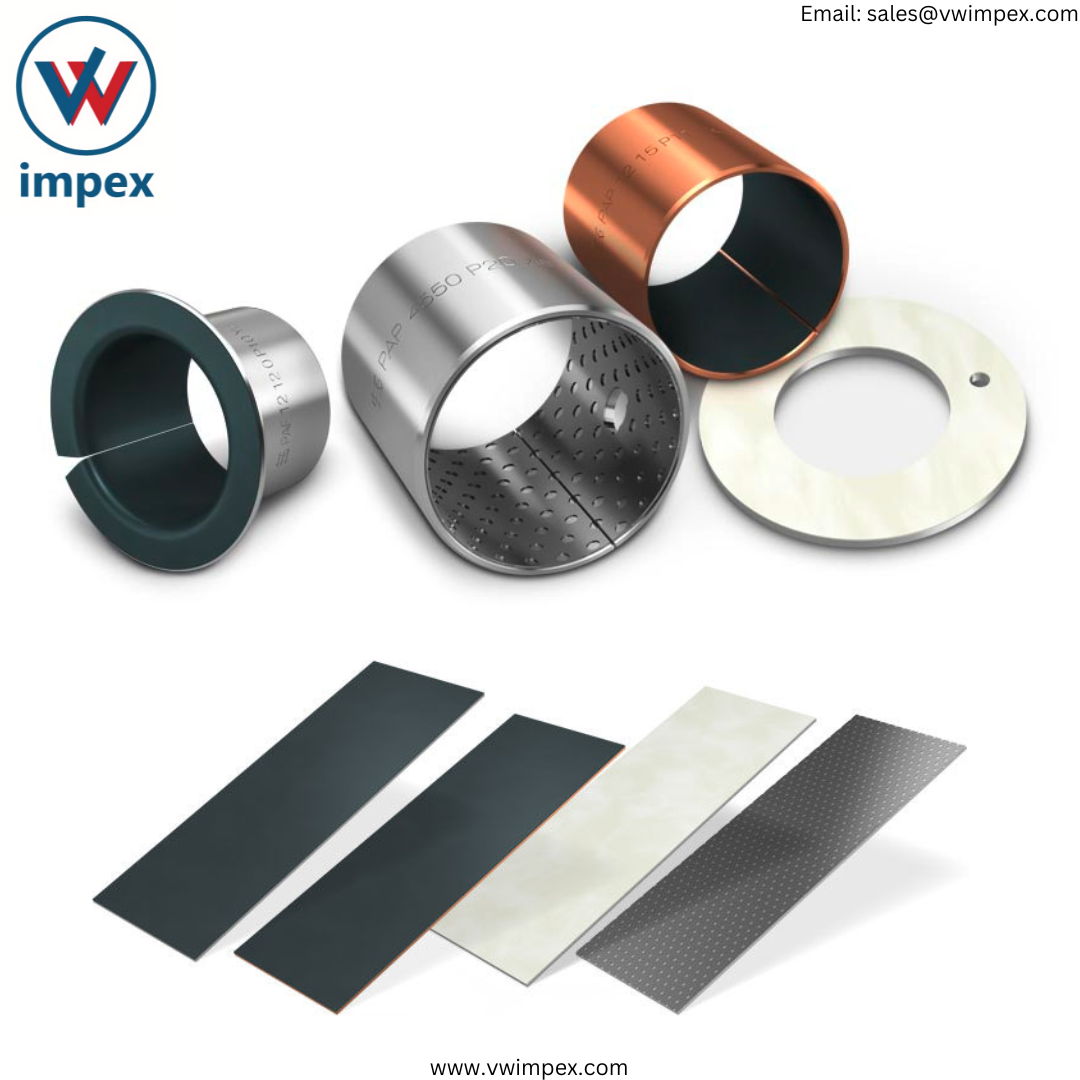

Permaglide plain bearings are bearings for very small radial or axial design envelopes. These products are available as bushes, flanged bushes, thrust washers and strips and in two groups of materials. The bushes are available not only in metric sizes but also in inch sizes.

Bushes, washers and strips are supplied in the maintenance-free Permaglide P1 or the low-maintenance P2. Flanged bushes are made from the maintenance-free Permaglide P1.

Embodies the product characteristic of a permanently, low-wear gliding. By applying a plastic material onto a metallic base alloy, a low friction matrix that unites favourable tribological properties with the load carrying properties and thermal conductivity of metals is obtained. The use of solid lubricants in the plastic matrix makes it possible to use Permaglide bearings in applications without oil- and grease lubrication.

Depending upon customer requirements and specific applications, a number of maintenance-free and low maintenance materials are available with identical microstructure. A porous bronze sinter structure applied to a steel or bronze back and is impregnated with the respective plastic mix. The solid lubricant produces a film between the sliding surfaces. It attributes to low-noise operation at constant speeds and low coefficients of friction throughout the entire service life of the component. This is achieved by means of a mixture of PTFE (Poly Tetra Fluoro Ethylene) with wear-retardant and thermally conductive additives.

It is not possible to find the desired solution for plain bearing applications with products made of maintenance-free materials for all duties and applications. For such duties and applications, low-maintenance materials are available. In this case, the sliding surface

taking up the wear load is formulated from a PVDF (Polyvinylidene Fluoride) matrix.

To reduce the coefficient of friction and improve thermal conductivity, special additives are mixed into the matrix. In addition, the surface of the sliding layer may optionally be equipped with lube bore relieves to accommodate grease or oil.

Exceptional Performance in Demanding Applications

The Permaglide Plain Bearing stands out for its ability to handle high loads and variable temperature ranges, making it a reliable choice for hydraulic cylinders, agricultural equipment, and construction machinery. Engineered with precision-ground surfaces and a self-lubricating design, it ensures smooth operation even under intense working conditions. Its metal-polymer composite enhances corrosion resistance, extending product lifespan in harsh environments.

Comprehensive Compliance and Versatile Use

This plain bearing is RoHS compliant, guaranteeing environmental safety in all applications. Featuring a dry/lubricated operation mode and robust color-coded design, it is especially suitable for distributors, exporters, importers, suppliers, and traders - particularly for German markets. With a high load capacity and superior material selection, it adapts effortlessly to various industrial requirements while maintaining regulatory compliance.

FAQ's of Permaglide Plain Bearing:

Q: How does the self-lubricating feature of the Permaglide Plain Bearing benefit hydraulic cylinders?

A: The self-lubricating design reduces friction and wear, ensuring consistent performance and minimizing maintenance needs in hydraulic cylinder applications, even during extended operations or exposure to harsh fluids.Q: What process is used to achieve the precision-ground surface finish?

A: The Permaglide Plain Bearing undergoes advanced grinding techniques to attain a precision-ground surface, which enhances its fit, reduces operational noise, and ultimately improves bearing life and system reliability.Q: When is the best time to use this bearing in agricultural machinery maintenance?

A: Optimal periods include scheduled machinery servicing or when signs of wear are detected in existing bearings, ensuring equipment runs smoothly and downtime is reduced in the field.Q: Where can distributors and importers source Permaglide Plain Bearings for German and international markets?

A: These bearings can be procured from authorized distributors, exporters, importers, and suppliers with direct links to German manufacturers, ensuring genuine products and full RoHS compliance.Q: What makes the Permaglide Plain Bearing suitable for both construction and automotive applications?

A: Its high static and dynamic load capacities, wide temperature tolerance range, and corrosion-resistant metal-polymer composite construction make it versatile for both rugged construction machinery and precise automotive systems.Q: How is corrosion resistance ensured in these plain bearings?

A: Corrosion resistance is achieved through the Permaglide metal-polymer composite material and precision-ground finish, which protect the bearing from environmental factors and chemical exposure.Q: What are the key benefits of the open seal type and single row structure?

A: The open seal type facilitates easier inspection and maintenance, while the single-row structure delivers a compact design optimized for high-load performance without compromising durability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bushings Category

INTERCOM Ball Cage Guide Pillars and Bushes

Price 14000 INR / Piece

Minimum Order Quantity : 2 Pieces

Precision Rating : High Precision

Lubrication Type : Other, Grease/Oil Lubrication

Material : Other, Alloy Steel/EN31/Hardened Steel

Limiting Speed : Up to 3000 rpm

Self Lubricating Bushings

Price 500 INR / Piece

Minimum Order Quantity : 6 Pieces

Precision Rating : ISO Standard

Lubrication Type : Other, Self Lubricating Solid Lubricant

Material : Other, Bronze/Composite

Limiting Speed : Up to 5000 rpm

AMES Self-lubricating Sintered Bush Bearings

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Precision Rating : ISO 9001 Standard

Lubrication Type : Other, Oiled / SelfLubricating

Material : Other, Sintered Bronze / Iron

Limiting Speed : Up to 6000 rpm

Oilite Bush

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Precision Rating : ISO Tolerance Class

Lubrication Type : Other, OilImpregnated

Material : Other, Sintered Bronze

Limiting Speed : Dependent on lubrication and operating conditions

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry