Self Lubricating Bushings

Price 500 INR/ Piece

Self Lubricating Bushings Specification

- Thickness

- 1 mm to 40 mm

- Lubrication Type

- Self Lubricating Solid Lubricant

- Cage Material

- Composite / Metal

- Retainer

- Solid

- Precision Rating

- ISO Standard

- Inside Diameter

- 10 mm to 200 mm

- Bearing Type

- Self Lubricating Bushing

- Material

- Bronze/Composite

- Structure

- Cylindrical Bush

- Seals Type

- No Seal

- Number Of Rows

- Single Row

- Bore Size

- 10 mm to 200 mm

- Outside Diameter

- 12 mm to 210 mm

- Limiting Speed

- Up to 5000 rpm

- Load Capacity

- Standard to Heavy Duty

- Noise Level

- Low

- Maintenance

- Maintenance-Free

- Finish

- Precision Machined

- Mounting Type

- Press Fit/Interference Fit

- Corrosion Resistance

- Yes, Excellent

- Operating Temperature Range

- -40°C to +250°C

- Color

- Metallic Brown/Gray

- Application

- Automotive, Industrial Machinery, Construction Equipment

- Coefficient of Friction

- Low (typically 0.03 to 0.18)

About Self Lubricating Bushings

Self-Lubricating Bushings

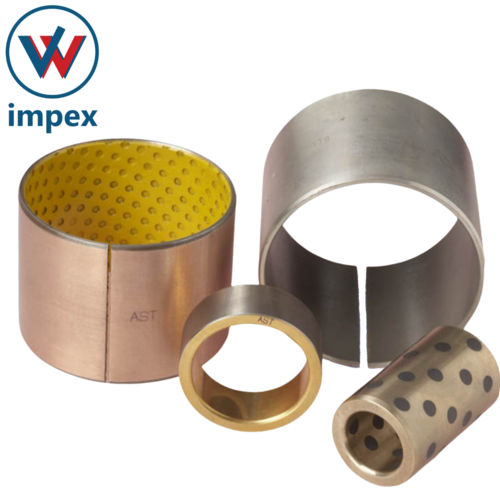

Self-lubricating bushings (lubrication free bushings) are made up of one of four basic compositions:

- Strong Cast Bronze with Solid Lubricants

- Bronze Wrapped Bushings

- Bronze Powder with Steel Material

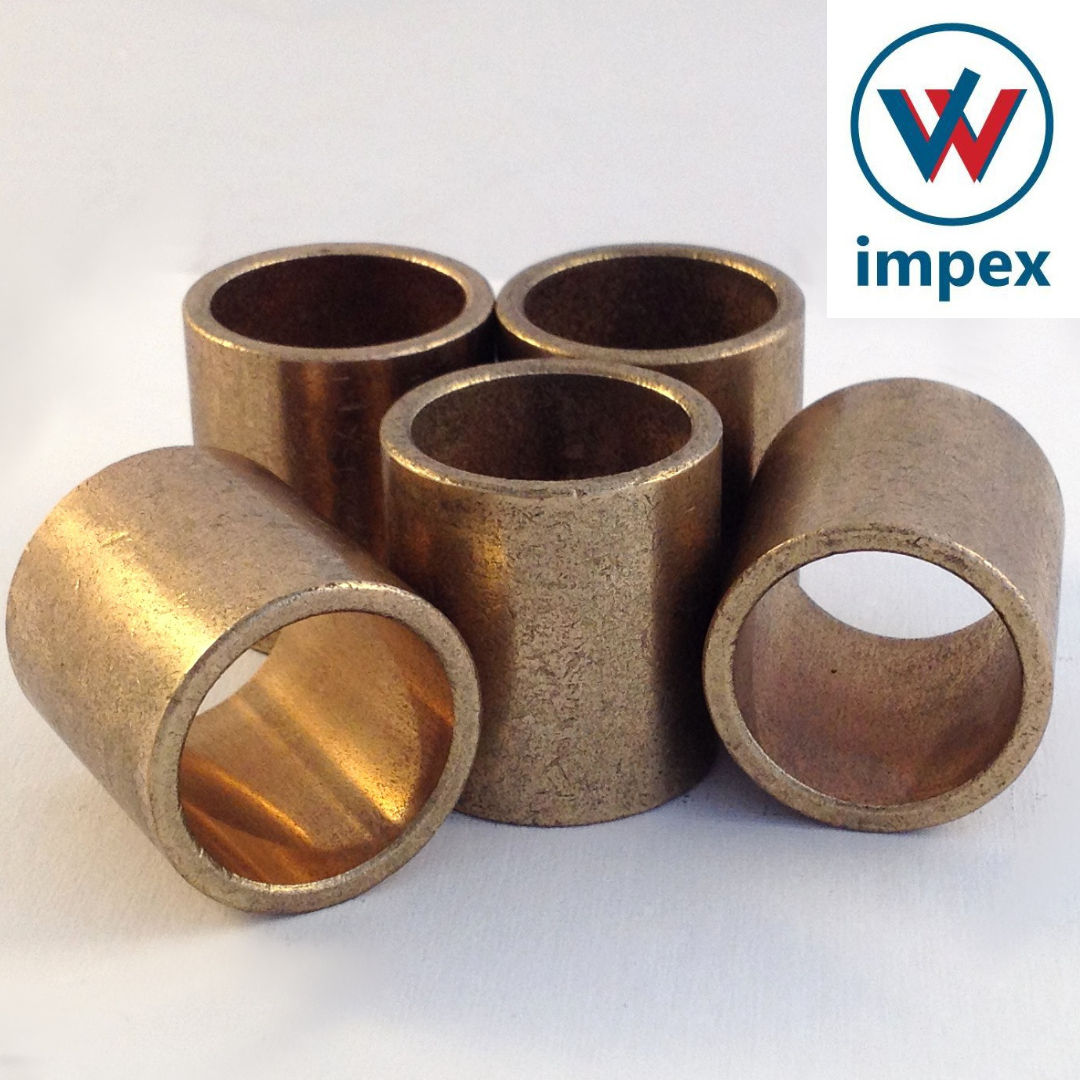

- Sintered Bronze

-

Composite Self-Lubricating Bushings

Self-lubricating bushings are made up of one of two basic compositions;

- PTFE-Based Metal-Polymer Materials

- Thermoplastic-Based Metal-Polymer Materials

Lubrication free bushings are used in applications where extreme agitation of parts and the force of friction to wear on parts. These self-lubricating bushings are able to withstand high temperatures and have high load-bearing tolerances.

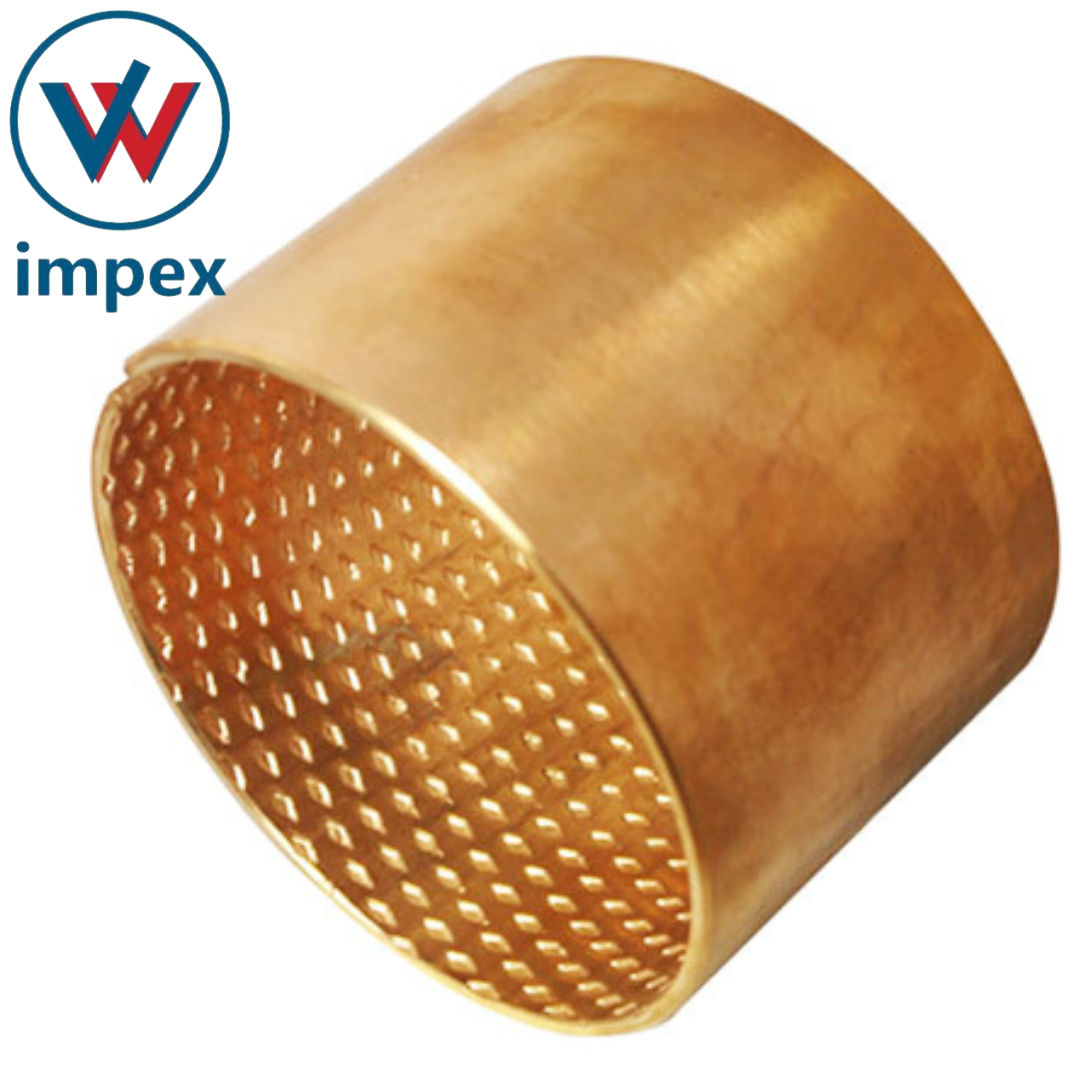

Bronze Backed, Bronze With PTFE Series - Metric

These Bushings are made of bronze backed with bronze powder PTFE/Pb, are dry bushings, and have the following layers:

- PTFE/Pb mixture 0.01-0.03mm, provides an excellent initial transfer film, which effectively coats the mating surface of the bushing assembly, forming an oxide type solid lubricant film.

- Sintered bronze powder 0.20-0.35mm, provides max. thermal conductivity away from the bushing surface, also serves as a reservoir for the PTFE-lead mixture.

- Bronze backing, gives exceptionally high load carrying capacity, excellent heat dissipation. Have very good corrosion resistance.

-

Steel Bronze With PTFE/Fiber Series - Metric

These Bushings are made of Steel bronze powder with PTFE/fiber, are dry bushings, and have the following layers:

- PTFE polymer fibers mixture 0.01-0.03mm are lead-free providing an excellent initial transfer film, which effectively coats the mating surface of the bushing assembly, forming an oxide type solid lubricant film.

- Sintered bronze powder 0.20-0.35mm, providing maximum thermal conductivity away from the bushing surface, also serves as a reservoir for the PTFE mixture.

- Steel backing, provides high load carrying capacity, excellent heat dissipation.

- Copper/Tin plating 0.002mm, provides good corrosion resistance

Steel Shell With POM Plastic Liner - Inch And Metric

These Bushings very similar to DX brand bushings in structure and are often substituted for DX bushings providing better value. Bushings are made of steel bronze powder with POM and have the following layers:

- POM 0.3-0.50mm, has high wear resistance and low friction even only minute quantities of lubricant are supplied, this bushing surface carries a pattern of circular indents which should be filled with grease on assembly of the bushing.

- Sintered bronze powder 0.20-0.35mm, provides max. thermal conductivity away from the bushing surface, also serves as a reservoir for the resin mixture.

- Low-carbon steel, gives exceptionally high load carrying capacity, excellent heat dissipation.

- Copper plating 0.002mm providing good corrosion resistance.

Steel Shell, Bronze Powder With PTFE Fiber - Inch And Metric

Metallic Self-Lubricating (Lubrication Free) Bushings

Wrapped Bronze Series - Metric Wrapped Bronze With Thru Holes Series - Metric Cast Bronze With Solid Lubricant Plugs - Metric

Bimetal Wrapped Steel With Bronze Series - Metric

Metal Backed Bronze Powder And Solid Lubricants Series - Metric Metal Backed Bronze Powder And Graphite Series - Metric

Versatile Use Across Industries

Self lubricating bushings are widely utilized in automotive, industrial machinery, and construction equipment, offering reliable performance in challenging environments. Their robust design and maintenance-free operation make them the preferred choice for applications that demand longevity and durability. With flexible sizes and optimized load capacity, these bushings address a wide spectrum of engineering requirements.

Precision Engineering and Durability

Manufactured from bronze or composite with a precision machined finish, these single-row bushings ensure tight tolerances and smooth operation. Their metallic brown/gray color and ISO standard rating reflect superior build quality. The solid lubricant structure enables continuous self-lubrication, greatly reducing wear and extending service life under high-stress conditions.

FAQ's of Self Lubricating Bushings:

Q: How do self lubricating bushings reduce the need for regular maintenance?

A: These bushings are constructed with solid lubricants embedded in their structure, allowing them to continuously self-lubricate during operation. This eliminates the need for external lubrication and regular maintenance, enhancing reliability and reducing downtime in machinery and vehicles.Q: What applications are ideal for using self lubricating bushings?

A: Self lubricating bushings are suitable for a variety of applications, including automotive systems, industrial machinery, and construction equipment. Their low friction, noise levels, and excellent corrosion resistance make them ideal for environments demanding consistent and high-performance operation.Q: When is it recommended to use bushings with no seals and a press fit mounting?

A: If the operating environment is free from heavy contamination or debris and the application allows for tight tolerances, using bushings with no seals and a press fit mounting is advantageous. This design simplifies installation while the self-lubricating properties protect against wear without extra seals.Q: Where can self lubricating bushings be sourced from in Germany?

A: These bushings can be acquired from reputable distributors, exporters, importers, suppliers, and traders specializing in bearing components across Germany. Ensure suppliers adhere to ISO standards for reliability and consistent quality.Q: What is the process for installing self lubricating bushings in machinery?

A: Installation involves pressing the bushing into a precisely sized housing using an interference fit method. Careful alignment and correct bore/outside diameter selection are essential for optimal performance. Once fitted, the bushing requires no ongoing lubrication.Q: How does the material choice (bronze or composite) benefit the bushing's performance?

A: Bronze offers strength, wear resistance, and high load capacity, suitable for demanding operations. Composite materials often enhance corrosion resistance, lower friction, and add versatility, making them ideal for a wider range of conditions.Q: What advantages do these bushings provide compared to conventional bearings?

A: Compared to conventional bearings, self lubricating bushings offer lower maintenance requirements, enhanced corrosion resistance, quieter operation, and reliable performance at a broad temperature range and speeds up to 5000 rpm.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bushings Category

INTERCOM Ball Cage Guide Pillars and Bushes

Price 14000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, Alloy Steel/EN31/Hardened Steel

Thickness : Standard/Customizable

Load Capacity : High Load Carrying Capacity

Bore Size : 6 mm to 50 mm

Permaglide Plain Bearing

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Other, Permaglide MetalPolymer Composite

Thickness : 16 mm

Load Capacity : High

Bore Size : 10 mm

Oilite Bush

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, Sintered Bronze

Thickness : 10 mm

Load Capacity : Medium Duty

Bore Size : 10 mm

Babbitt Impregnated Graphite Carbon Bushing

Price 3500

Minimum Order Quantity : 5 Pieces

Material : Other, Babbitt Impregnated Graphite/Carbon

Thickness : 3 mm to 30 mm

Load Capacity : High

Bore Size : Customizable

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry