Oilite Bush

Price 1200 INR/ Piece

Oilite Bush Specification

- Lubrication Type

- Oil-Impregnated

- Cage Material

- Bronze

- Thickness

- 10 mm

- Precision Rating

- ISO Tolerance Class

- Inside Diameter

- 10 mm

- Bearing Type

- Self-Lubricating Bush

- Material

- Sintered Bronze

- Structure

- Cylindrical, Plain Sleeve

- Number Of Rows

- Single

- Bore Size

- 10 mm

- Outside Diameter

- 13 mm

- Limiting Speed

- Dependent on lubrication and operating conditions

- Load Capacity

- Medium Duty

- Manufacturing Process

- Powder Metallurgy

- Temperature Range

- -20C to 120C

- Maintenance

- Low

- Application

- Automotive, Industrial Machinery, Pumps, Fans

- Compliance

- RoHS Compliant

- Life Expectancy

- Long Service Life

- Resistant To

- Corrosion and Wear

- Colour

- Bronze

- Hardness

- 6580 HRB

- Installation

- Press Fit

- Finish

- Smooth

About Oilite Bush

Oilite Bushings

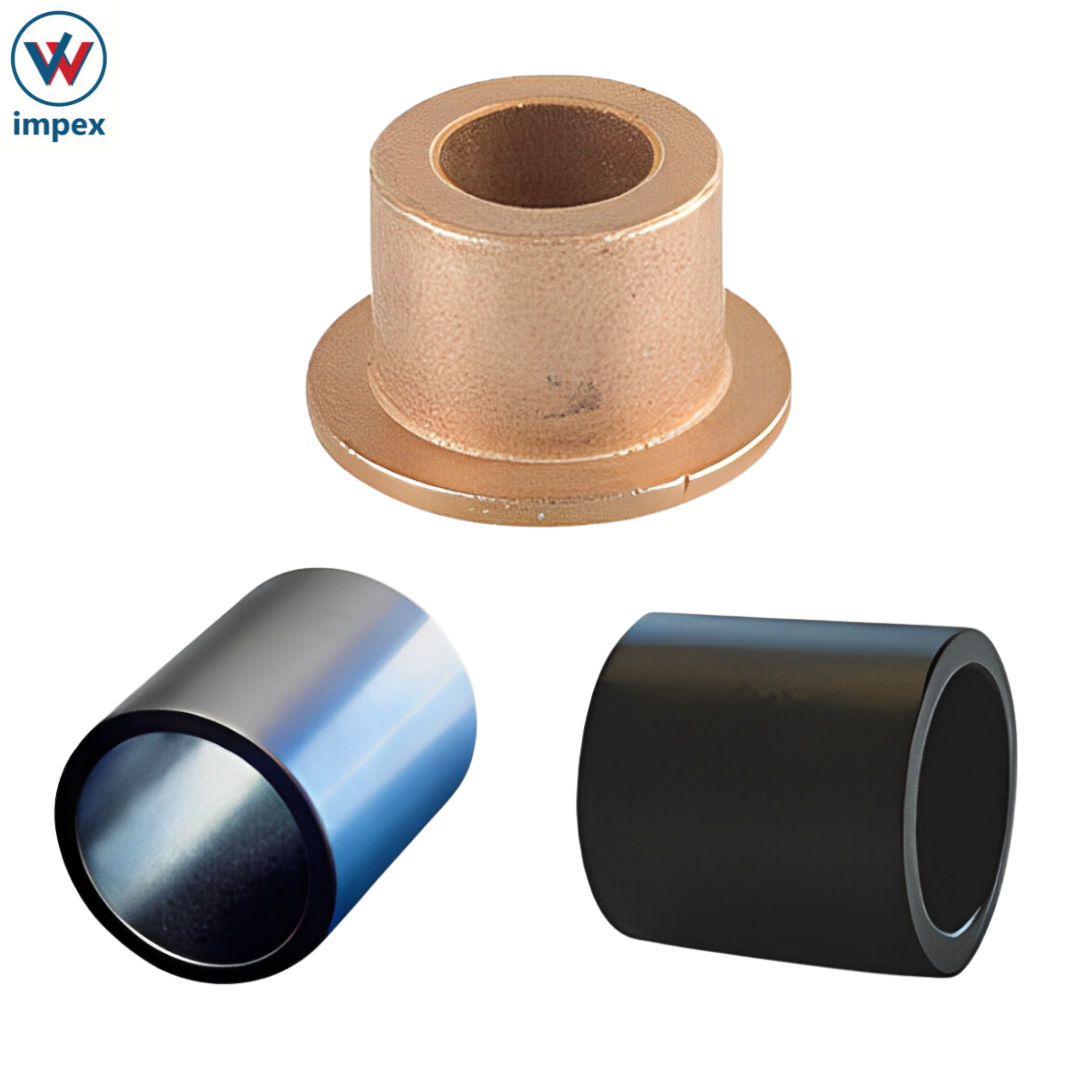

Oilite bushings are highly reliable and innovative industrial components that work in systems across a range of industries. These parts consist of an oil-infused porous sintered bronze material, which is why theyre known for their self-lubrication and long-lasting performance capabilities.

Material Composition of Oilite Bushings

Oilite bushings are precision-engineered using sintered bronze, which creates a porous structure throughout the material. This porous design allows it to be infused with oil lubricant, which continually lubricates the surface of the bearing.

Through self-lubrication, Oilite bushings reduce friction while preventing gradual wear and tear, resulting in long-lasting parts that optimize efficiency and cost-effectiveness for many applications.

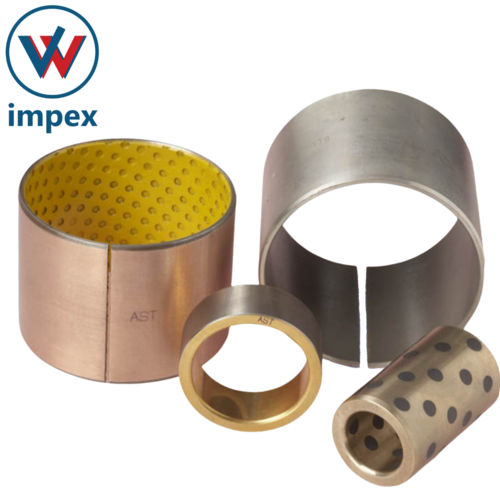

Oilite Bushings vs. Bronze Bushings vs. Plastic Bushings

Oilite bushings offer certain benefits over traditional plastic and bronze bushings. Without sintering, bronze bushings are durable and reliable but dont have self-lubricating properties. Plastic bushings arent as durable as conventional bronze or Oilite bushings, as they are likely to experience more wear and tear under load-bearing applications.

Unlike bronze and plastic bushings, Oilite bushings sintered bronze design offers superior durability and self-lubrication that make them more efficient compared to regular manual lubrication. These bushings are capable of withstanding heavy loads while reducing friction, making them highly durable options for use in harsh environmental conditions.

Maintenance of Oilite Bushings

Oilite bushings are also easy to maintain. They must undergo periodic cleaning, and its critical to use the right lubricants. Over time, as the bushings experience wear and tear, you must inspect them for damage and replace them as needed.

Generally, the durability of these parts will depend on the types of lubrication used, environmental conditions, and storage methods. With proper maintenance and inspections, youll be able to maximize the longevity of Oilite bushings.

Common Industries and Applications for Oilite Bushings

Many applications and industries use Oilite bushings because of their unique advantages. Some of the specific applications include:

Industrial equipment

Packaging Machinery

Aerospace components

Household appliances

Agricultural equipment

Lawn and garden equipment

Conveyor systems

Construction Equipment

Material handling systems

Railway brake systems

Hoists and cranes

Reliable Performance Across Applications

Designed for versatility, the Oilite Bush delivers optimal performance in automotive systems, industrial equipment, pumps, and fans. Its self-lubricating sintered bronze structure minimizes friction and wear, ensuring long-term reliability even in demanding environments. Its smooth finish and precise ISO Tolerance Class ratings guarantee a perfect fit and reduced downtime.

Advanced Material and Manufacturing

Engineered from high-grade sintered bronze using powder metallurgy, this bush provides sturdy resistance to corrosion and wear. The oil-impregnated bronze ensures the bearing remains lubricated throughout its service life, reducing maintenance requirements while maximizing operational efficiency. Its RoHS compliance assures environmental safety and quality.

Simple Installation and Lasting Durability

The Oilite Bush's press-fit installation means quick, hassle-free setup in single-row, plain sleeve configurations. Designed for moderate loads and a wide range of speeds (dependent on lubrication and conditions), it sustains long service intervals. Its low-maintenance, self-lubricating properties make it the preferred choice for many distributors and end users.

FAQ's of Oilite Bush:

Q: How is the Oilite Bush installed in automotive or machinery applications?

A: The bush is designed for press-fit installation, which means you simply press the bushing into the prepared housing bore. This method ensures a secure and precise fit, making it suitable for easy integration in both automotive and industrial machinery components.Q: What makes the Oilite Bush suitable for heavy-duty industrial use?

A: Thanks to its sintered bronze construction and oil-impregnated, self-lubricating design, the bush resists wear and corrosion under medium-duty loads. Its ISO Tolerance Class precision and smooth finish contribute to longevity and dependable operation in harsh industrial environments.Q: When should the Oilite Bush be replaced or inspected?

A: Due to its long service life and low maintenance requirements, the bush often operates reliably for extended periods. Regular inspection is recommended as part of preventive maintenance routines, especially when exposed to high loads or harsh conditions, to ensure continued optimal performance.Q: Where can the Oilite Bush be utilized besides automotive and industrial machinery?

A: Beyond automotive and industrial applications, the Oilite Bush is well-suited for pumps, fans, and other rotating equipment where cylindrical, sleeve-type bearings are needed, particularly in medium-duty or continuous-use scenarios.Q: What benefits does the oil-impregnated, self-lubricating design provide?

A: The oil-impregnated structure ensures continuous lubrication throughout the bearing's life, minimizing friction, reducing wear, and lowering maintenance demands. This results in quieter operation, extended part lifespan, and decreased downtime.Q: How does the manufacturing process enhance the bush's performance and reliability?

A: The bush is manufactured using powder metallurgy, which yields a porous structure allowing oil impregnation. This innovation supports consistent self-lubrication and imparts excellent load-carrying and heat dissipation properties, making the bush reliable in various temperature and operational ranges.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bushings Category

Self Lubricating Bushings

Price 500 INR / Piece

Minimum Order Quantity : 6 Pieces

Material : Other, Bronze/Composite

Structure : Cylindrical Bush

Bore Size : 10 mm to 200 mm

Inside Diameter : 10 mm to 200 mm

AMES Self-lubricating Sintered Bush Bearings

Price 500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Sintered Bronze / Iron

Structure : Cylindrical Bush

Bore Size : 10 mm to 50 mm (customization available)

Inside Diameter : 10 mm to 50 mm

Babbitt Impregnated Graphite Carbon Bushing

Price 3500

Minimum Order Quantity : 5 Pieces

Material : Other, Babbitt Impregnated Graphite/Carbon

Structure : Cylindrical Bushing

Bore Size : Customizable

Inside Diameter : Customizable

Permaglide Plain Bearing

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Other, Permaglide MetalPolymer Composite

Structure : Plain

Bore Size : 10 mm

Inside Diameter : 10 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry