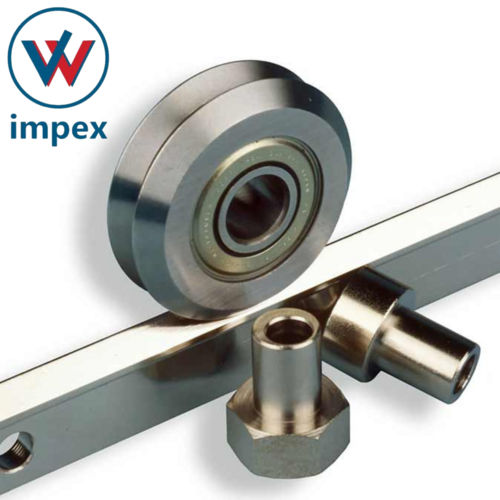

Track Roller RV and LV

Price 520 INR/ Piece

Track Roller RV and LV Specification

- Weight

- 0.95 Kg

- Thickness

- 15 mm

- Material

- Alloy Steel

- Ball Bearing Type

- Deep Groove Ball Bearing

- Roller Bearing Type

- Tapered Roller Bearing

- Bushes Type

- Steel Bush

- Structure

- Single Piece Welded

- Seals Type

- Rubber Sealed

- Number Of Rows

- Double Row

- Bore Size

- 20 mm

- Outside Diameter

- 52 mm

- Limiting Speed

- 3000 RPM

- Load Capacity

- 1200 Kg

- Inner Diameter

- 20 mm

- Hardness

- 58-62 HRC

- Usage Life

- Up to 5 Years

- Packaging Type

- Corrugated Box

- Mounting Type

- Bolt-On

- Application

- Overhead Conveyor, Material Handling Systems

- Temperature Range

- -25°C to +90°C

- Surface Finish

- Black Oxide Coated

- Corrosion Resistance

- Yes

About Track Roller RV and LV

Track roller with "V" groove profile on outer ring

Series RV OR LV

These tracks have a groove " V " shaped with an included angle of 120*.

This guarantees a smooth low friction movement and a good distribution of the radial load. The structure of the " V " groove track roller with two rows of steel balls corresponds to the structure of the angular contact bearings. The units are supplied with steel protection shields and steel and rubber contact shields.

Characteristics of the guide system that series LV bearings are applied.

1) Low resistance long service life widely uses

The roughness of the " V " profile surface can be reached to Ra032 processed by precision grind. The bearings have well parallelism between the " V " profile groove and the mount planes of inner ring relatively. When bearings working the stresses between the bearing and cylindrical track is in equality and the friction resistance is low.

2) Easy installation

After bearing assembled the concentric or eccentric pivot installation will be convenient To adjust the eccentric ones eccentricity the bearing can get the fitting proload.

Engineered for Industrial Reliability

The Track Roller RV and LV is designed for use in overhead conveyor and material handling systems. With robust alloy steel construction, double-row support, and premium bearing technology, it provides steady performance even under high loads.

Optimized Performance and Longevity

With a hardness of 58-62 HRC and black oxide surface finish, this track roller resists wear and corrosion. Its rubber-sealed structure keeps contaminants out, while high-quality internal components ensure an impressive service life and minimal maintenance.

Easy Installation and Maintenance

Equipped with a bolt-on mounting type and packaged in a protective corrugated box, the roller is easy to install or replace. Clear markings and accessible fittings make it suitable for distributors, exporters, importers, suppliers, and traders seeking efficiency.

FAQ's of Track Roller RV and LV:

Q: How is the Track Roller RV and LV protected against corrosion?

A: The track roller features a black oxide-coated surface and rubber-sealed bearings, providing effective resistance against corrosion in harsh working environments.Q: What materials are used in the construction of the Track Roller RV and LV?

A: This track roller is manufactured from high-grade alloy steel with steel bushes, ensuring durability, strength, and reliable load handling.Q: When should the Track Roller RV and LV be replaced during usage?

A: With an expected usage life of up to five years under normal operating conditions, replacement is recommended if performance declines or visible wear occurs before this period.Q: Where can the Track Roller RV and LV be used effectively?

A: It is ideal for overhead conveyor systems and material handling applications, especially in industrial settings requiring high load capacity and corrosion resistance.Q: What is the process for mounting this track roller?

A: The roller is designed for bolt-on mounting, making the installation process straightforward and quick, suitable for both new setups and replacements.Q: How does the double-row structure benefit the roller's operation?

A: The double-row configuration provides enhanced load distribution and stability, reducing stress on internal components and extending the roller's operational life.Q: What are the main benefits of using this track roller in material handling systems?

A: Key advantages include high load capacity, smooth operation due to precision bearings, excellent corrosion resistance, and low maintenance requirements, making it a cost-effective choice.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Track Rollers & Wheel Bearings Category

Bishop Wisecarver Bearing

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Single Row

Ball Bearing Type : Other, Precision Ball Bearing

Bore Size : 6 mm

Seals Type : Double Sealed

Double V Guide Wheel Bearings W OR RM

Price 950 INR / Piece

Minimum Order Quantity : 2 Pieces

Structure : Double Row

Ball Bearing Type : Other, Double V Guide Wheel

Bore Size : 8 mm

Seals Type : Rubber Sealed

ITEM Roller Guide Track Rollers

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Structure : Single Row Roller

Ball Bearing Type : Other, Deep Groove Ball Bearing

Bore Size : 12 mm

Seals Type : Contact Seals

Harhues and Teufert Linear Systems and Roller Bearings

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Single Row / Double Row

Ball Bearing Type : Other, Deep Groove Ball Bearings

Bore Size : 10 mm 80 mm

Seals Type : Double Sealed

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry