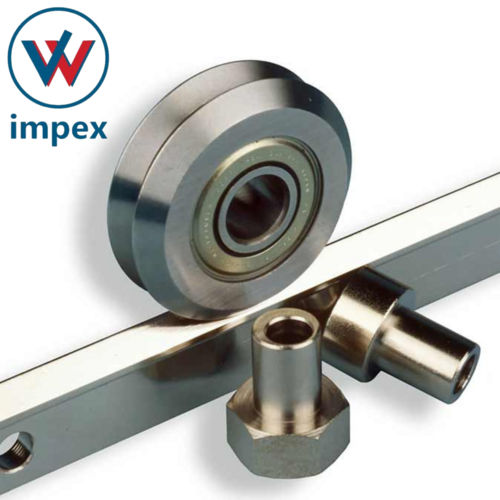

ITEM Roller Guide Track Rollers

Price 4000 INR/ Piece

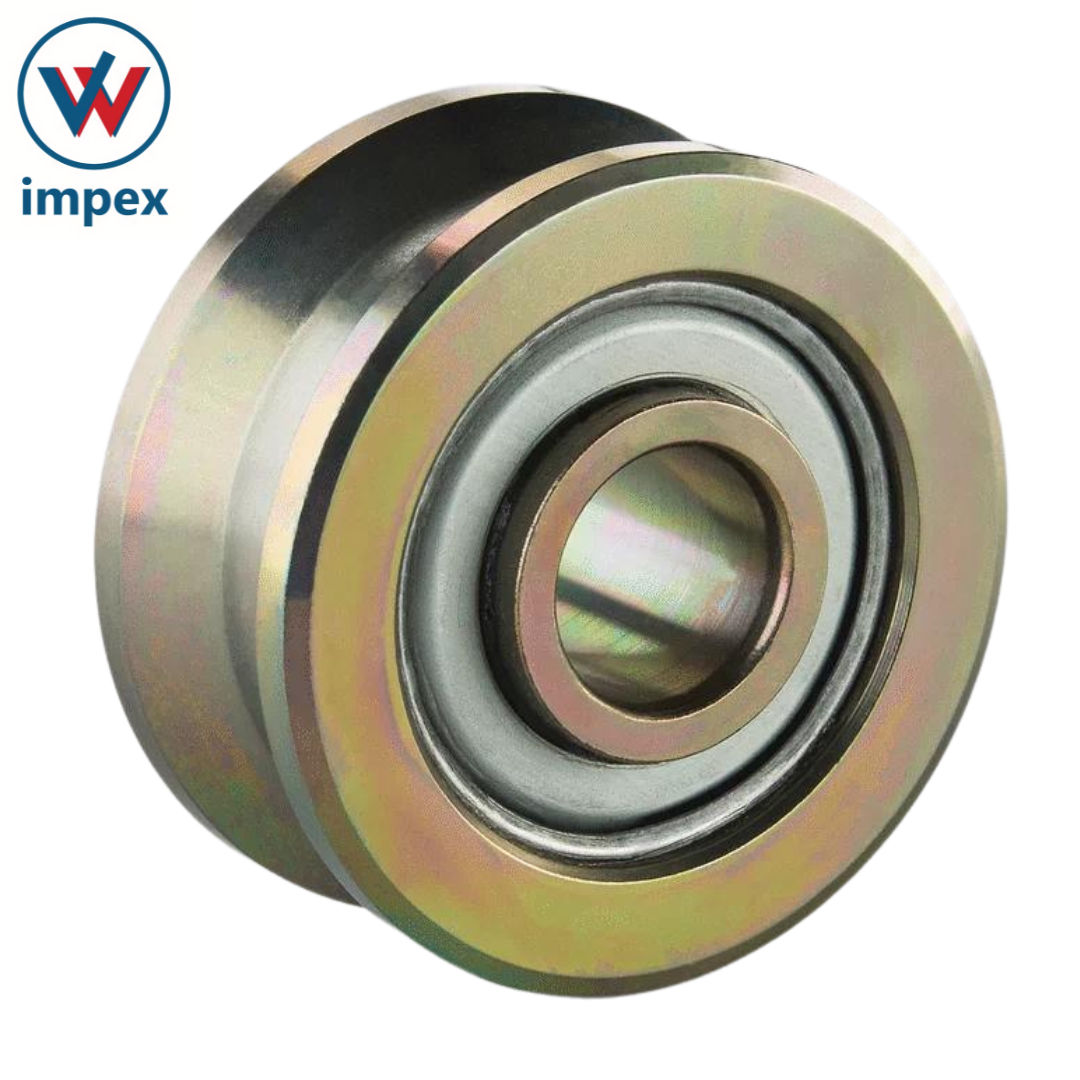

ITEM Roller Guide Track Rollers Specification

- Thickness

- 15 mm

- Weight

- 0.23 kg

- Material

- High-grade Steel

- Ball Bearing Type

- Deep Groove Ball Bearing

- Roller Bearing Type

- Precision Track Roller Bearing

- Bushes Type

- Heat-treated Steel Bush

- Structure

- Single Row Roller

- Seals Type

- Contact Seals

- Number Of Rows

- 1

- Bore Size

- 12 mm

- Outside Diameter

- 40 mm

- Limiting Speed

- 8000 RPM

- Load Capacity

- 750 kg

- Inner Diameter

- 12 mm

- Surface Treatment

- Zinc Plated

- Lubrication

- Pre-lubricated

- Corrosion Resistance

- Yes

- Noise Level

- Low

- Color

- Metallic Silver

- Application

- Guiding and supporting linear motion in track systems

- Operating Temperature Range

- -20°C to +120°C

- Mounting Type

- Bolt-on

About ITEM Roller Guide Track Rollers

The item product portfolio comprises more than 4000 high-quality components designed for use in machine bases, work benches, automation solutions and lean production applications.

After the usage of aluminium profiles in stationary designs, Linear slide elements were added to the product portfolio. Instead of being screwed into place, the steel shafts of these elements were pressed into the standard grooves of the profile. That was a brand new and low-cost solution - for guides of virtually any length. It also saved a great deal of assembly time. This modular linear guide system based on the Line 8 profiles of the MB system became the first in a long line of dynamic applications.

Linear Guides

* Roller Guides on shafts secured to the profile groove

* C-Rail Guides in special profiles

* Linear Guide Systems on guide rails on profiles 8

* Ball Bearing Guide Bushes on free-standing guiding shafts

Roller Guides

The modular Roller Guides feature ease of assembly, high load-bearing capacity, a choice of stroke length and high travelling speed. It consists of:

* Shaft Clamp Profiles

* Bearing Units

* Double bearing Units

* End cap & Lubricating systems

* Bolts

* Roller Profiles

* Recirculating Ball Units

* Carriages & Carriage Sets

* Rollers

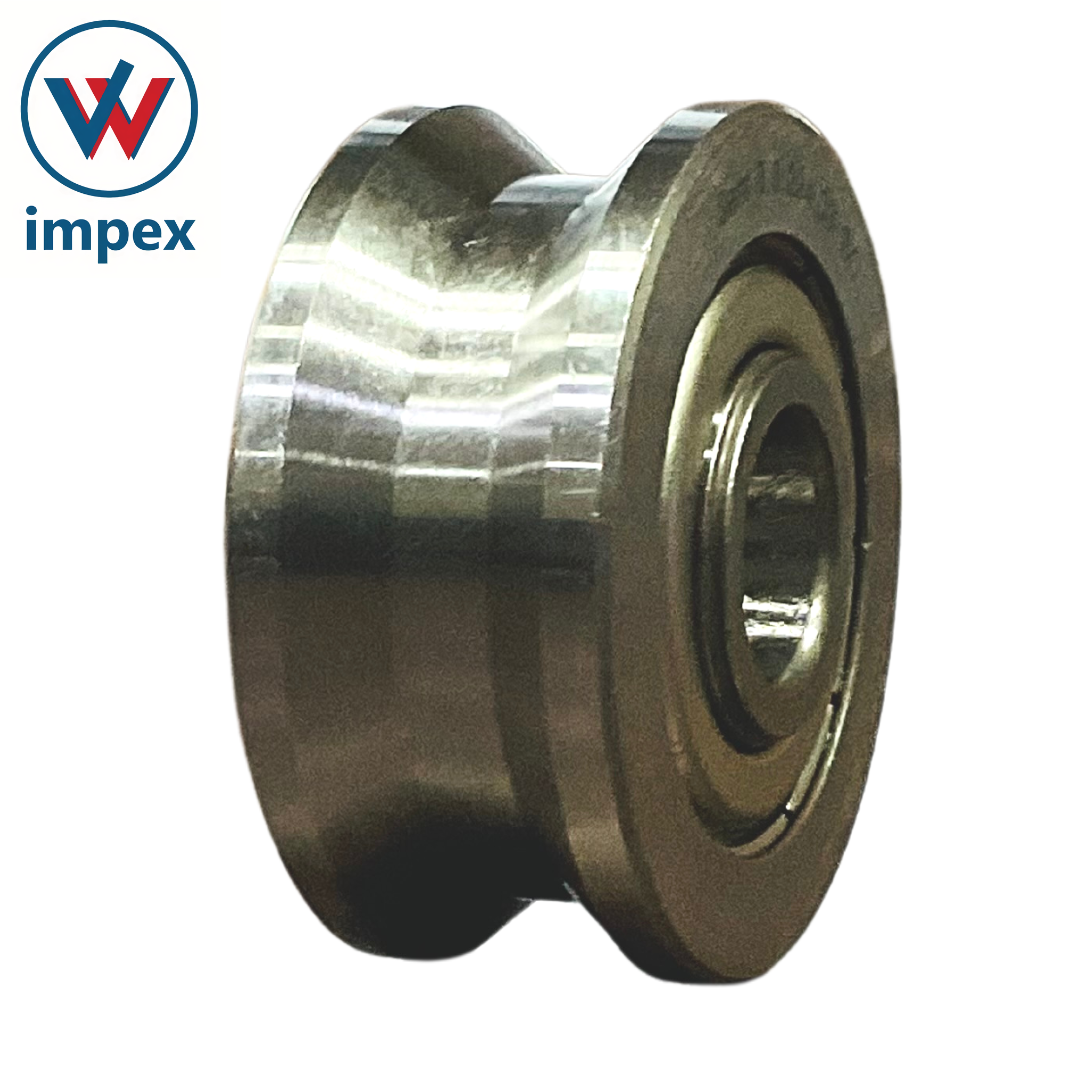

Rollers

Rollers are used for building customized Bearing Units, Compatible Roller Profiles available, Maintenance-free.

* Rollers D6

* Roller D10

* Rollers D14 from item are perfect for constructing customized Bearing Units. Maintenance-free and RoHS-compliant.

* Roller D14K

* Roller D14 Stainless Steel

* Roller D25

Shaft Clamp Profiles

* For using standard profiles as a basis for linear slides.

* For fastening the Shafts for Linear Units to standard profiles.

* Easy to install thanks to clip-in technology.

Bearing Units & Double bearing Units

* Wide range of models for all load requirements.

* Easy-running and strong rollers.

* Suitable for any size of slide thanks to modular design.

Roller Profiles

* For building customized Bearing Units up to 3,000 mm in length.

* For use with compatible Rollers and Bolts.

Outstanding Performance in Linear Motion

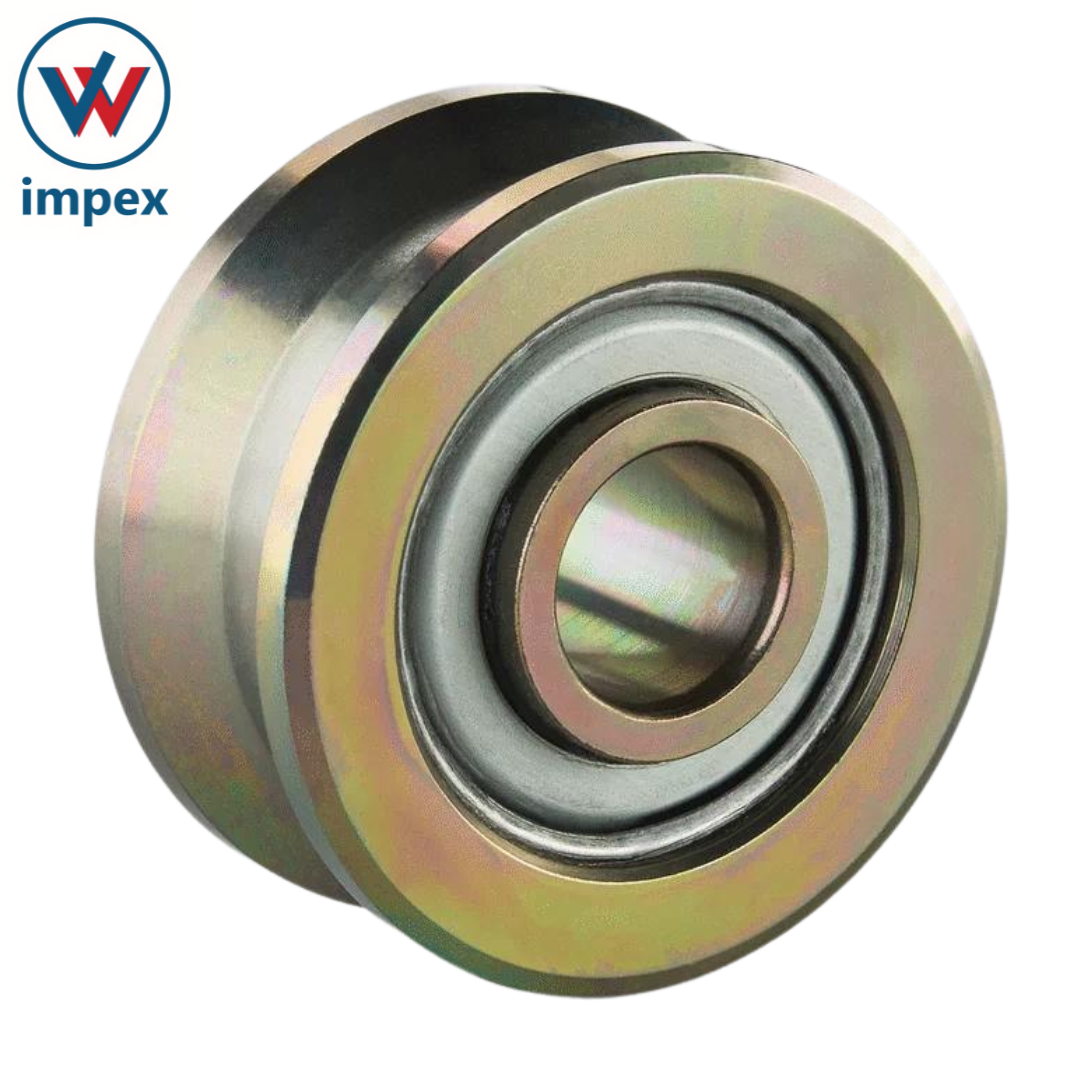

Designed to support and guide linear motion applications, the ITEM Roller Guide Track Rollers ensure smooth, stable, and precise movement along track systems. The combination of a single-row design, deep groove ball bearings, and pre-lubrication enables minimal friction while maintaining excellent load-bearing capabilities and extended service life.

Built for Durability and Resistance

Manufactured from high-grade steel and surface-treated with zinc plating, these rollers are engineered to resist corrosion-even in more demanding conditions. Their heat-treated steel bushes and contact seals guard internal components, ensuring consistent performance in temperature ranges from -20C to +120C. This robust construction protects against premature wear and environmental impacts.

Versatile and Easy Installation

With a bolt-on mounting type, these rollers are quick to install and suitable for a wide range of industrial setups, from factory automation to material transport. Their compact, precise dimensions and low-noise performance provide flexibility and comfort for integration within existing or new track systems, especially in German engineering environments.

FAQ's of ITEM Roller Guide Track Rollers:

Q: How do you install the ITEM Roller Guide Track Rollers in a linear motion track system?

A: Installation is straightforward with the bolt-on mounting type. Simply align the roller with the track, secure it using suitable bolts through the provided bore size of 12 mm, and ensure that the assembly is well-tightened to maintain smooth motion.Q: What benefits does the zinc-plated surface treatment provide for the rollers?

A: The zinc-plated surface significantly enhances corrosion resistance, protecting the high-grade steel from rust and environmental wear. This extends the roller's lifespan, even in challenging industrial settings or humid environments.Q: When is it necessary to replace the ITEM Roller Guide Track Rollers?

A: Replacement is recommended if you notice increased noise, diminished smoothness, or visible signs of wear after prolonged use. Even with pre-lubrication and high durability, inspecting the rollers as part of regular maintenance ensures continued optimal performance.Q: Where are these rollers typically used, and can they operate in harsh conditions?

A: These rollers are extensively used in industrial machinery, conveyors, and automation systems that require precise linear guidance. Their temperature range from -20C to +120C, corrosion resistance, and sturdy construction enable reliable operation in both standard and harsh environments.Q: What is the process for maintaining the pre-lubricated ITEM Roller Guide Track Rollers?

A: Routine maintenance mainly involves periodic inspections to check for debris or uncommon wear. Since the rollers are pre-lubricated and sealed, lubrication intervals can be extended, reducing downtime and maintenance requirements.Q: How does the deep groove ball bearing type enhance roller performance?

A: Deep groove ball bearings offer low-friction, efficient high-speed rotation up to 8,000 RPM and support both radial and axial loads. This ensures quiet, steady operation and precise motion control-key for track systems needing dependable guidance.Q: What are the main benefits of using a single-row precision track roller bearing structure?

A: A single-row bearing structure minimizes friction while delivering high load capacity (up to 750 kg) and excellent running accuracy. This design ensures a compact size and lightweight form (only 0.23 kg), optimizing efficiency for linear motion applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Track Rollers & Wheel Bearings Category

Bishop Wisecarver Bearing

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Thickness : 6 mm

Inner Diameter : 6 mm

Outside Diameter : 19 mm

Track Roller RV and LV

Price 520 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Alloy Steel

Thickness : 15 mm

Inner Diameter : 20 mm

Outside Diameter : 52 mm

Double V Guide Wheel Bearings W OR RM

Price 950 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : High Carbon Chrome Steel

Thickness : 10 mm

Inner Diameter : 8 mm

Outside Diameter : 24 mm

Harhues and Teufert Linear Systems and Roller Bearings

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Bearing Steel

Thickness : 8 mm 30 mm

Inner Diameter : 10 mm 80 mm

Outside Diameter : 26 mm 110 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry