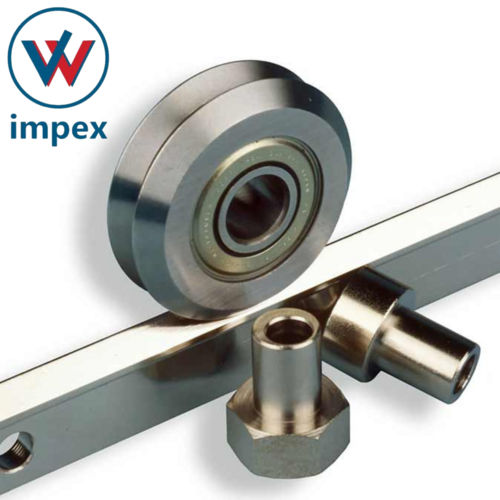

Double V Guide Wheel Bearings W OR RM

Price 950 INR/ Piece

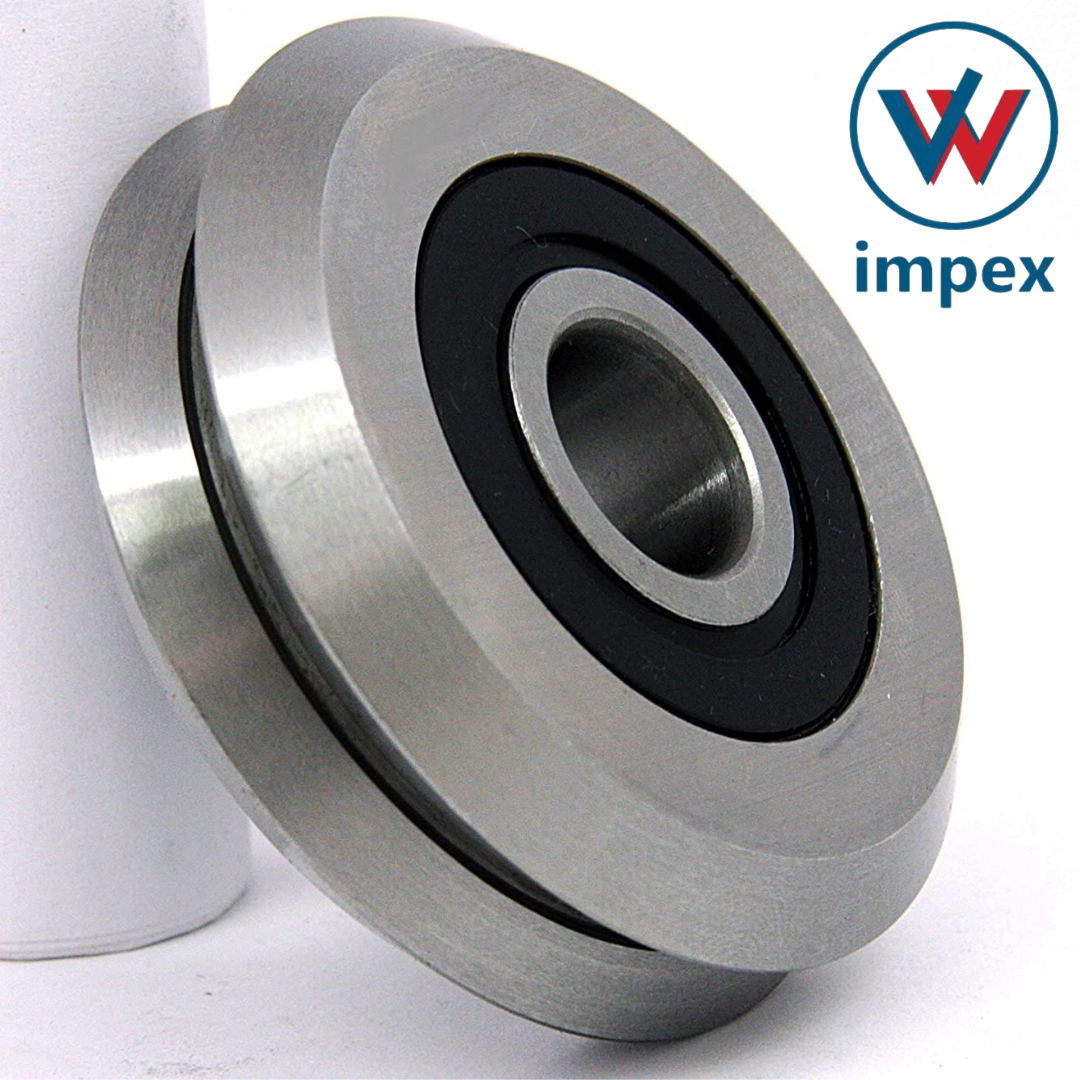

Double V Guide Wheel Bearings W OR RM Specification

- Weight

- 45 g

- Thickness

- 10 mm

- Material

- High Carbon Chrome Steel

- Ball Bearing Type

- Double V Guide Wheel

- Roller Bearing Type

- V-Groove Roller

- Bushes Type

- Steel Bushes

- Structure

- Double Row

- Seals Type

- Rubber Sealed

- Number Of Rows

- 2

- Bore Size

- 8 mm

- Outside Diameter

- 24 mm

- Limiting Speed

- 8000 RPM

- Load Capacity

- 500 kg

- Inner Diameter

- 8 mm

- Corrosion Resistance

- Yes

- Application

- Linear Motion Systems, CNC Machinery

- Packaging Type

- Box

- Hardness

- 60-62 HRC

- Dynamic Load Rating

- 750 N

- Operating Temperature Range

- -20°C to +120°C

- Static Load Rating

- 1100 N

- Lubrication

- Grease Filled

- Surface Finish

- Polished

- Mounting Type

- Bolt-On

- Precision Class

- ABEC-3

About Double V Guide Wheel Bearings W OR RM

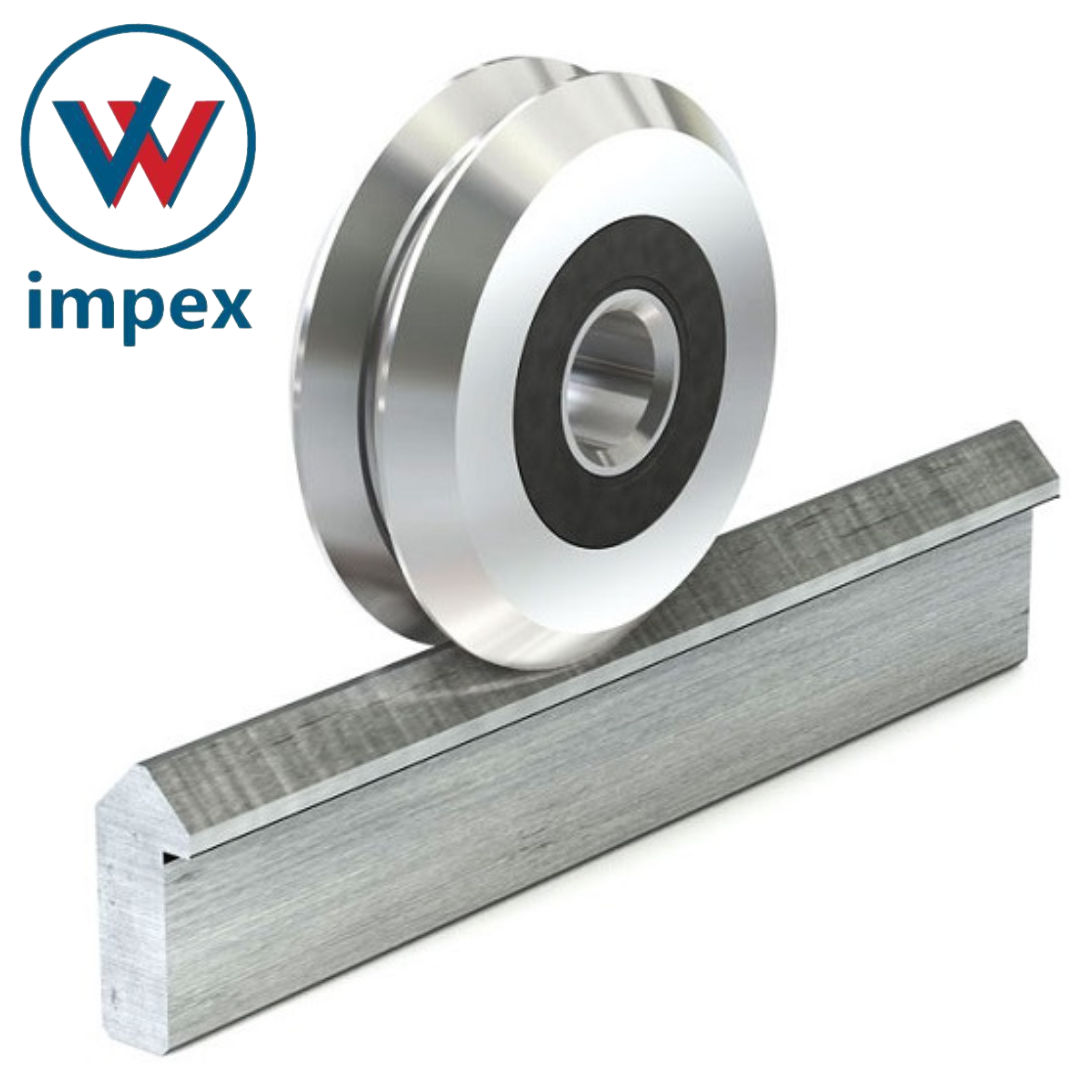

Double V Guide Wheel Bearings

These components are used in a variety of applications including x-y tables.The type guide wheel bearings are precision ground, double row, angular contact bearings. These bearings are pre-lubricated and available in either 52100 chrome or 440C stainless steel. Although the standard chrome steel version is available either sealed or shielded, the stainless steel design is available sealed only. The concentric and adjustable bushings provide a simple, effective means of adjusting the free play of the guide wheel system.

Item No.: W1,W1X,W1SSX

Description:Guide Wheel Bearings, W (RM) Track Roller

Bore: 0.1875"(4.7625mm)

Width: 0.310"(7.874mm)

Outerside Diameter: 1.5748"(40mm)

Seal Type: Sealed or Shield,

Application: Aerospace and Defense,Medical Equipment,Semiconductor Equipment,Food and Packaging Equipment etc.

Item No.: W2,W2X,W2SSX

Description:Guide Wheel Bearings, W (RM) Track Roller

Bore: 0.375"(9.525mm)

Width: 0.4375"(11.1125mm)

Outerside Diameter: 1.210"(30.734mm)

Seal Type: Sealed or Shield,

Application: Aerospace and Defense,Medical Equipment,,Semiconductor Equipment,Food and Packaging Equipment etc.

Item No.: W3,W3X,W3SSX

Description:Guide Wheel Bearings, W (RM) Track Roller

Bore: 0.4724"(12.00mm)

Width: 0.625"(15.875mm)

Outerside Diameter: 1.803"(45.796mm)

Seal Type: Sealed or Shield,

Application: Aerospace and Defense,Medical Equipment,,Semiconductor Equipment,Food and Packaging Equipment etc.

Item No.: W4,W4X,W4SSX

Description:Guide Wheel Bearings, W (RM) Track Roller

Bore: 0.5906"(15.0 mm)

Width: 0.75"(19.05mm)

Outerside Diameter: 2.360"(59.944mm)

Application: Aerospace and Defense,Medical Equipment,,Semiconductor Equipment,Food and Packaging Equipment etc.

Engineered for Precision Linear Motion

Navigating demanding industrial environments, Double V Guide Wheel Bearings guarantee smooth, precise linear motion in CNC machinery and automation systems. The ABEC-3 precision class ensures optimal performance, while the robust double row design enhances load capacity and operational reliability. These bearings excel in both durability and accuracy for intricate tasks.

Unmatched Durability and Corrosion Resistance

Manufactured from high carbon chrome steel and finished with a polished surface, these bearings provide elevated hardness (60-62 HRC) and outstanding corrosion resistance. The hard-wearing material and rubber seals extend service life, even in challenging conditions, making them perfect for exporters, importers, distributors, and traders in Germany and beyond.

Ready for High-Speed and Heavy-Load Applications

With a limiting speed of 8000 RPM and the capability to support up to 500 kg, these bearings are engineered for both speed and strength. Grease-filled lubrication and bolt-on mounting simplify installation and maintenance, ensuring long-term, trouble-free performance in high-demand setups.

FAQ's of Double V Guide Wheel Bearings W OR RM:

Q: How do Double V Guide Wheel Bearings enhance linear motion in CNC machinery?

A: The Double V Guide Wheel Bearings feature a precision ABEC-3 rating and double-row V-groove design, which ensure stable guidance and smooth roller movement along tracks. This minimizes vibration and ensures accurate positioning in CNC machinery and other linear motion applications.Q: What is the advantage of using high carbon chrome steel with a polished finish in these bearings?

A: High carbon chrome steel, combined with a polished surface, offers superior hardness (60-62 HRC) and durability. This construction resists wear and corrosion, making the bearings reliable in harsh environments and extending their operational lifespan.Q: When should these bearings be considered for replacement or maintenance?

A: Replacement or maintenance is recommended if you notice increased vibration, unusual noise, or excessive wear in your machinery. Regular inspection is advised, especially in high-cycle applications, to ensure optimal performance and prevent unscheduled downtime.Q: Where are these Double V Guide Wheel Bearings typically used?

A: They are widely used in linear motion systems, CNC machinery, and machine tool guides across industries. These bearings are suitable for installation in environments requiring high precision and load-bearing capacity, such as automated production lines and robotics.Q: What is the installation process for these bearings?

A: Installation is straightforward, as the bearings are designed for bolt-on mounting. Ensure the mounting surface is clean and aligned, attach the bearing firmly with bolts, and check for smooth movement along the guide track to prevent misalignment.Q: How does the rubber sealing benefit the performance of these bearings?

A: The rubber seals protect the interior of the bearing from contaminants such as dust, debris, and moisture, enhancing the life and reliability of the bearing. This is particularly valuable in industrial environments where exposure to contaminants could compromise performance.Q: What are the benefits of choosing grease-filled lubrication for these bearings?

A: Grease-filled lubrication ensures consistent, low-maintenance operation by minimizing friction and wear. This type of lubrication also aids in keeping contaminants out and reducing the frequency of re-lubrication, making it ideal for continuous-use applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Track Rollers & Wheel Bearings Category

Bishop Wisecarver Bearing

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Limiting Speed : 18000 RPM

Roller Bearing Type : Other, VGroove Roller Bearing

Outside Diameter : 19 mm

ITEM Roller Guide Track Rollers

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Highgrade Steel

Limiting Speed : 8000 RPM

Roller Bearing Type : Other, Precision Track Roller Bearing

Outside Diameter : 40 mm

Harhues and Teufert Linear Systems and Roller Bearings

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Bearing Steel

Limiting Speed : 5000 rpm

Roller Bearing Type : Other, Linear Roller Bearings

Outside Diameter : 26 mm 110 mm

Track Roller RV and LV

Price 520 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Alloy Steel

Limiting Speed : 3000 RPM

Roller Bearing Type : Other, Tapered Roller Bearing

Outside Diameter : 52 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry