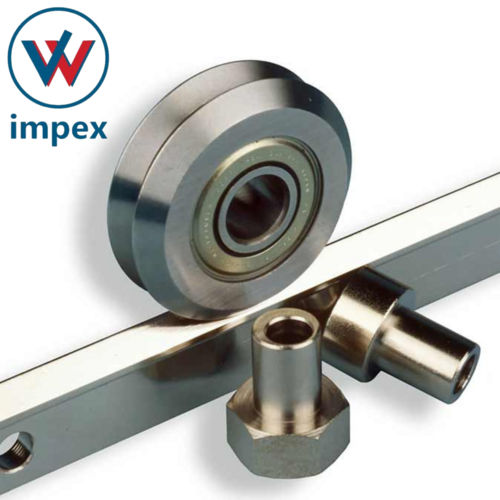

Nadella Guide Rollers

Price 6500 INR/ Piece

Nadella Guide Rollers Specification

- Weight

- From 0.05 kg to 1.5 kg depending on model

- Thickness

- 6 mm to 30 mm

- Material

- Alloy Steel

- Ball Bearing Type

- Single Row, Double Row

- Roller Bearing Type

- Cylindrical Roller

- Structure

- Guide Roller with Ball/Cylindrical Rollers

- Seals Type

- 2RS (Double Rubber Seal), ZZ (Shielded)

- Number Of Rows

- Single, Double

- Bore Size

- 8 mm to 50 mm

- Outside Diameter

- 22 mm to 120 mm

- Limiting Speed

- Up to 18000 rpm

- Load Capacity

- Up to 12000 N

- Inner Diameter

- 8 mm to 50 mm

- Surface Treatment

- Heat Treated and Ground

- Temperature Range

- -20°C to +120°C

- Precision Rating

- P0, P6

- Feature

- Corrosion resistant, Low noise, Maintenance free

- Mounting Type

- Stud Type or Yoke Type

- Application

- Linear motion systems, Automation, Material handling

About Nadella Guide Rollers

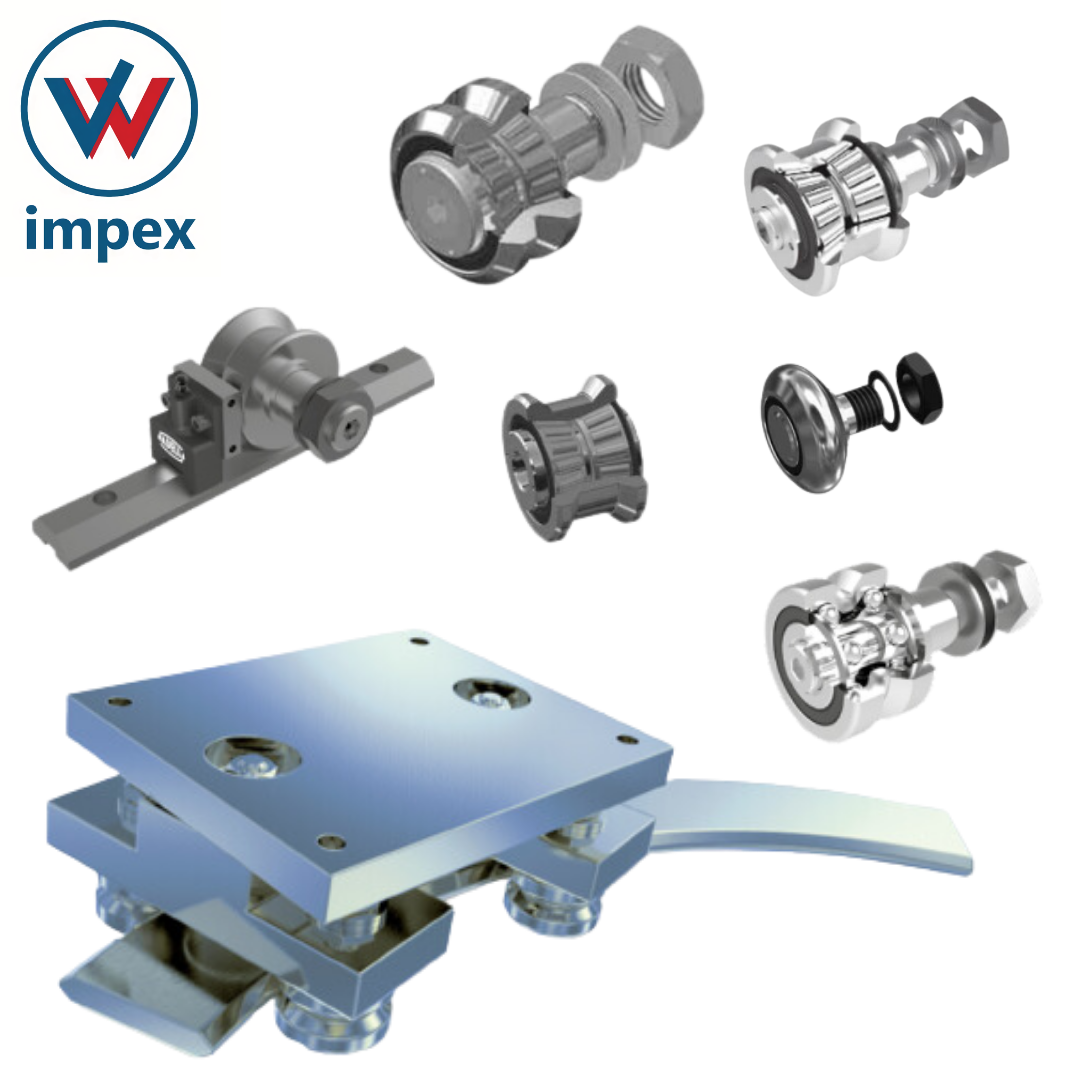

Nadella is specialized in the design and production of linear guide rail and rollers, divided into heavy and light load families, suitable for all applications where high speed and low noise are required and the operating environment is very aggressive. Their rails can be supplied with a single length of 6 meters, can be cut and drilled according to the customers' needs and can be jointed together. The main application fields of Nadella's linear guide systems are the following: Robotic, handler and pick & place systems, Packaging, Machine Tools, Wood Working Machines, Assembly Machines, Measure Instruments, Electro-medical Machines, Print machines. Linear guide systems for heavy loads This family of Nadella products consists of linear guides for simple installation at reasonable cost yet able to support high loads, at high velocity and function reliably in aggressive environments.

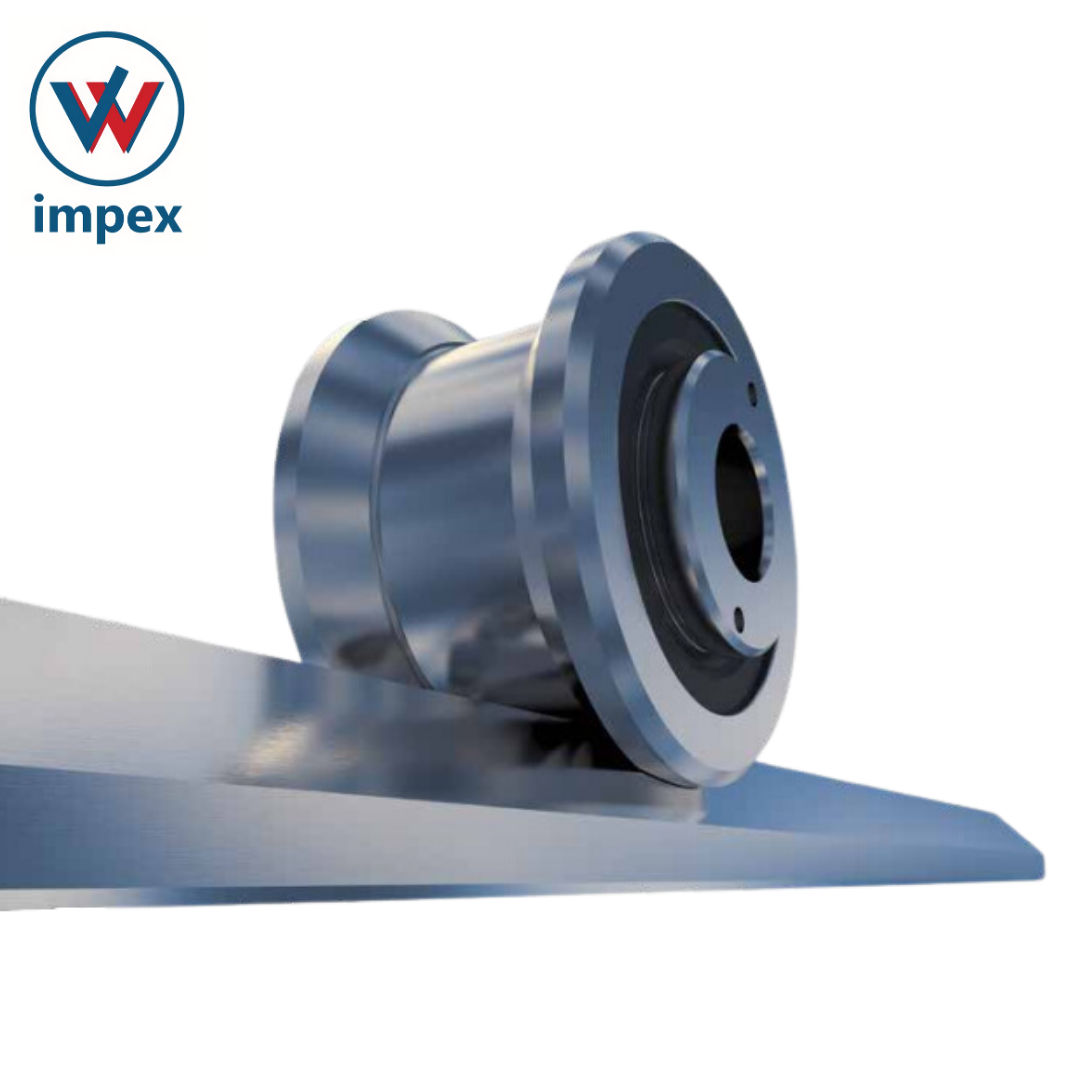

The most typical applications are in the foundry industry, steel fabrication equipment, metal stamping and transfer systems, automatic storage systems and material elevators among others. The family consists of rail designs GU, FS, FSH and GP. All are cold drawn solid bearing steel with induction hardened race surfaces that can be supplied both with sandblasted or ground surface treatment. Guide rollers are executed in ball, needle or tapered roller bearing designs to offer a wide range of load capacities at various price levels.

NADELLA provide a wide range of guide rollers to be able to meet different technical and economic requirements. All guide rollers are produced in concentric and eccentric versions to allow backlash adjustment during assembly on final equipment. Eccentric rollers are identified by additional R in the code.

The sides of the races of the guide roller are slightly convex. Besides reducing rolling friction, this also permits offsetting slight guide flexing or small assembly alignment errors.

Guide rollers based on needle or tapered roller bearings (FRN...EI, RK ..., PK ...) are recommended for critical applications with heavy axial loads and / or shock loading. Guide rollers based on ball bearings (FR ... EU, PFV, RCL) are more suitable for lighter loads or high dynamic systems.

The carriages based on Rolbloc's system are recommended for applications with heavy loads, high frequency of work and aggressive environment (dust, abrasive).

NADELLA Guide Rollers Series RKU FKU FR FRR FRN FRNR FRLK FRLR

NADELLA Guide Rollers RKY RKYR FKY PK PKR FK PFV PFVR RKO RKOR

Engineered Durability and Precision

Nadella Guide Rollers are manufactured from high-quality alloy steel that undergoes heat treatment and precision grinding, resulting in superior hardness, strength, and corrosion resistance. With options for single or double rows and different roller or bearing types, they accommodate diverse operational demands, ensuring stability and longevity for automation, linear motion, and material handling equipment.

Wide Operating Range and Versatile Sealing

Designed to perform in temperatures ranging from -20C to +120C, Nadella Guide Rollers are suitable for both indoor and challenging outdoor environments. The choice between double rubber seal (2RS) and shielded (ZZ) types provides flexibility for applications requiring enhanced protection against contaminants or reduced friction for higher speeds.

FAQ's of Nadella Guide Rollers:

Q: How do Nadella Guide Rollers contribute to maintenance-free operation in automation and material handling systems?

A: Nadella Guide Rollers utilize sealed precision ball or cylindrical rollers, heat-treated alloy steel construction, and advanced surface treatments. These features minimize friction and prevent ingress of dust or contaminants, resulting in long service life and minimal maintenance requirements, even in demanding industrial environments.Q: What is the installation process for stud type and yoke type Nadella Guide Rollers?

A: Stud type rollers are mounted directly onto equipment using a threaded stud, making installation quick and secure. Yoke type rollers, on the other hand, are installed on shafts or axles, offering flexibility for different mounting setups. Both methods ensure precise alignment and stable support for linear motion systems.Q: Where are Nadella Guide Rollers best utilized within industrial applications?

A: These rollers are ideal for integration in linear motion systems, material handling machinery, and automation equipment across sectors such as logistics, packaging, and manufacturing. Their corrosion resistance and versatility also make them suitable for harsh or variable environments.Q: What benefits does the heat-treated and ground surface provide to the guide rollers?

A: Heat treatment increases the hardness and durability of the alloy steel rollers, while precise grinding ensures a smooth surface for quiet and stable operation. This process enhances wear resistance, extends product lifespan, and maintains consistent performance at high speeds and loads.Q: When should you use 2RS (double rubber seal) versus ZZ (shielded) seal types on these rollers?

A: Use 2RS sealed rollers in environments where protection against moisture and debris is essential, as the rubber seals provide superior sealing. ZZ shielded types are preferable for applications requiring lower friction and higher rotational speeds, such as high-speed conveyors or automated systems operating in cleaner settings.Q: How do I select the right bore and outer diameter for my application?

A: Determine your load and space requirements, then match the bore size (8 mm to 50 mm) and outside diameter (22 mm to 120 mm) according to your application's specifications. Nadella's wide range accommodates different machinery sizes and load capacities up to 12,000 N, ensuring optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Track Rollers & Wheel Bearings Category

Bishop Wisecarver Bearing

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : 35 g

Seals Type : Double Sealed

Load Capacity : 600 N

Structure : Single Row

ITEM Roller Guide Track Rollers

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Weight : 0.23 kg

Seals Type : Contact Seals

Load Capacity : 750 kg

Structure : Single Row Roller

Harhues and Teufert Linear Systems and Roller Bearings

Price 20000 INR / Piece

Minimum Order Quantity : 1 Piece

Weight : Varies as per model (typically 0.1 kg 2.5 kg)

Seals Type : Double Sealed

Load Capacity : Up to 12000 N

Structure : Single Row / Double Row

Double V Guide Wheel Bearings W OR RM

Price 950 INR / Piece

Minimum Order Quantity : 2 Pieces

Weight : 45 g

Seals Type : Rubber Sealed

Load Capacity : 500 kg

Structure : Double Row

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry