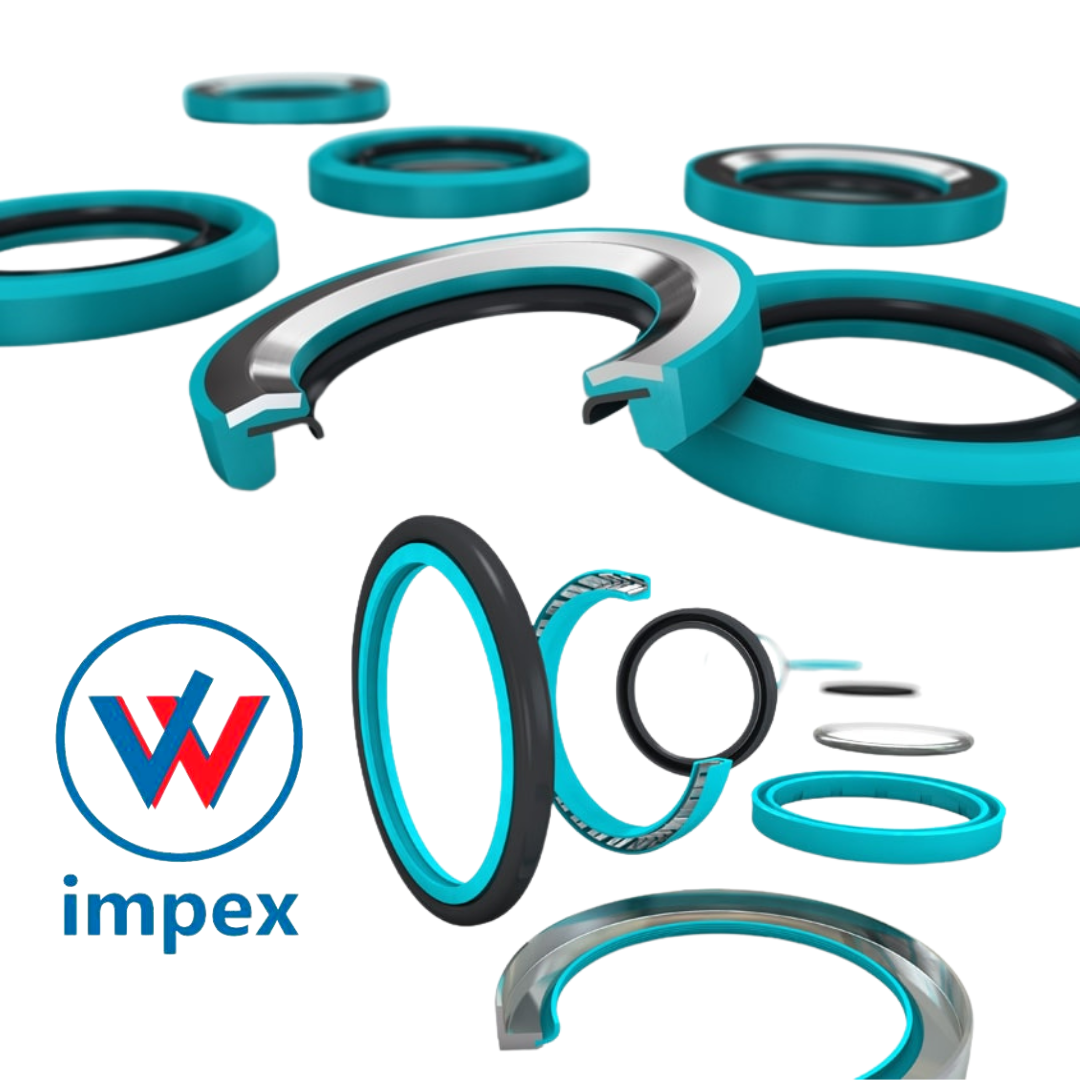

Trelleborg Oil Seal

Price 5000 INR/ Piece

Trelleborg Oil Seal Specification

- Hardness

- 70 - 90 Shore A

- Feature

- Excellent resistance to oils, fats, and hydrocarbons; High wear resistance

- Tolerance

- 0.05 mm

- Material

- Nitrile Rubber (NBR)

- Style

- Rotary Shaft Seal

- Shape

- Round

- Temperature

- -40C to +120C

- Application

- Sealing rotating shafts in hydraulic and pneumatic systems, automotive and industrial machinery

- Width Range

- 5 mm to 30 mm

- Color

- Black

- Inner Diameter Range

- 10 mm to 300 mm

- Type

- Single Lip

- Outer Diameter Range

- 20 mm to 320 mm

- Pressure Resistance

- Up to 0.05 MPa

About Trelleborg Oil Seal

Founded in 1952, Trelleborg Sealing Solutions was previously a part of the Smiths Group's precision seals business. This business, Polymer Sealing Solutions, consisted of four rubber units. These were Busak+Shamban, Dowty Automotive, Shamban and Forsheda. In 2003, Polymer Sealing Solutions was acquired by Trelleborg AB.

One-Stop-Shop For Sealing Solutions

Trelleborg Sealing Solutions offers you everything from the versatile elastomer O-Ring to complex multi-faceted PTFE based and polyurethane geometries. And in the unlikely event that none of these suit your requirements, we can develop a specific product for your application.

- Aircraft Seals

- Electronic Catalog

- Engineered Molded Parts

- Flat gaskets

- Healthcare & Medical Solutions

- Hydraulic Piston Seals

- Hydraulic Rod Seals

- Hydraulic Scrapers/Wipers

- Hydraulic Seals

- Hydraulic Wear Rings

- Latest Innovations

- Liquid Silicone Rubber

- Marine Bearings

- Mechanical Face Seals

- Oil & Gas Sealing Solutions

- Oil Seals

- O-Rings

- Pneumatic Seals

- Polymer Bearings & Bushings

- Proprietary Materials

- Rotary Seals / Shaft Seals

- Rubore Seals

- Rubore Shims

- Sealing Profiles

- Semiconductor PureFab FFKM

- Silicone Tubing & Hose

- Static Seals

- Surface Finishing

Versatile Applications Across Industries

The Trelleborg single lip oil seal is widely used in hydraulic and pneumatic systems, automotive, and industrial machinery. Engineered to maintain a reliable seal on rotating shafts, it ensures optimal equipment performance and longevity. Its superior material and construction make it suitable for a variety of operating environments where oil, fat, and hydrocarbon resistance are critical.

Precision Engineering and Robust Performance

Manufactured with strict adherence to tolerances and hardness specifications, this seal provides consistent, leak-free operations. Pressure resistance of up to 0.05 MPa and a wide working temperature range make it adaptable for different mechanical demands. The use of premium NBR material ensures lasting performance and helps reduce maintenance cycles.

FAQ's of Trelleborg Oil Seal:

Q: How does the Trelleborg Oil Seal enhance equipment performance in industrial settings?

A: The oil seal maintains an effective barrier on rotating shafts, preventing fluid leakage and ingress of contaminants. Its high wear resistance and precise tolerance contribute to longer equipment life and reduced maintenance requirements in industrial applications.Q: What process should be followed for installing the single lip rotary shaft seal?

A: Begin by cleaning the shaft and housing surfaces thoroughly. Confirm the correct dimensions using the provided size range, then carefully press the seal into place, ensuring it sits flush and does not twist or deform. For optimum sealing, ensure the lip is properly lubricated during installation.Q: Where can this oil seal be used within automotive systems?

A: It is suitable for use in engines, gearboxes, and differential assemblies where sealing rotating shafts is essential for preventing oil leaks and maintaining clean lubrication systems.Q: What benefits does nitrile rubber (NBR) provide for this oil seal?

A: Nitrile rubber offers excellent resistance to oils, fats, and hydrocarbons, making it ideal for environments where exposure to such substances is frequent. It also delivers high tensile strength and temperature stability, keeping the seal effective under challenging operating conditions.Q: When should the Trelleborg Oil Seal be replaced?

A: Replacement is recommended if leakage is observed, during routine maintenance, or when signs of wear such as cracking, hardening, or deformation are detected. Regular inspections help ensure optimal sealing and system reliability.Q: How is the pressure resistance of up to 0.05 MPa significant for hydraulic and pneumatic systems?

A: This pressure rating ensures the seal can handle typical system pressures, preventing oil or fluid loss while maintaining integrity and performance under operational loads common in hydraulic and pneumatic machinery.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Rings Category

Nilos Ring

Price 500 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Hardness : 6090 Shore A

Material : Nitrile

Temperature : 40C to +120C

SKF OIL SEALS

Price 500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Hardness : 6090 Shore A

Material : Nitrile Rubber (NBR), Fluoroelastomer (FKM), Polyacrylate (ACM)

Temperature : 40C to +200C (depending on material)

Dichtomatik Freudenberg FST Seals

Price 1500 INR / Piece

Minimum Order Quantity : 5 Pieces

Shape : Circular / Custom

Hardness : 70 to 90 Shore A

Material : NBR, FKM, EPDM, HNBR, VMQ

Temperature : 40C to +200C

Garlock Sealing Solutions

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Shape : Round, Rectangular, Custom

Hardness : 30 90 Shore A

Material : Nitrile Rubber, EPDM, PTFE, Graphite, Silicone

Temperature : 60C to 250C

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry