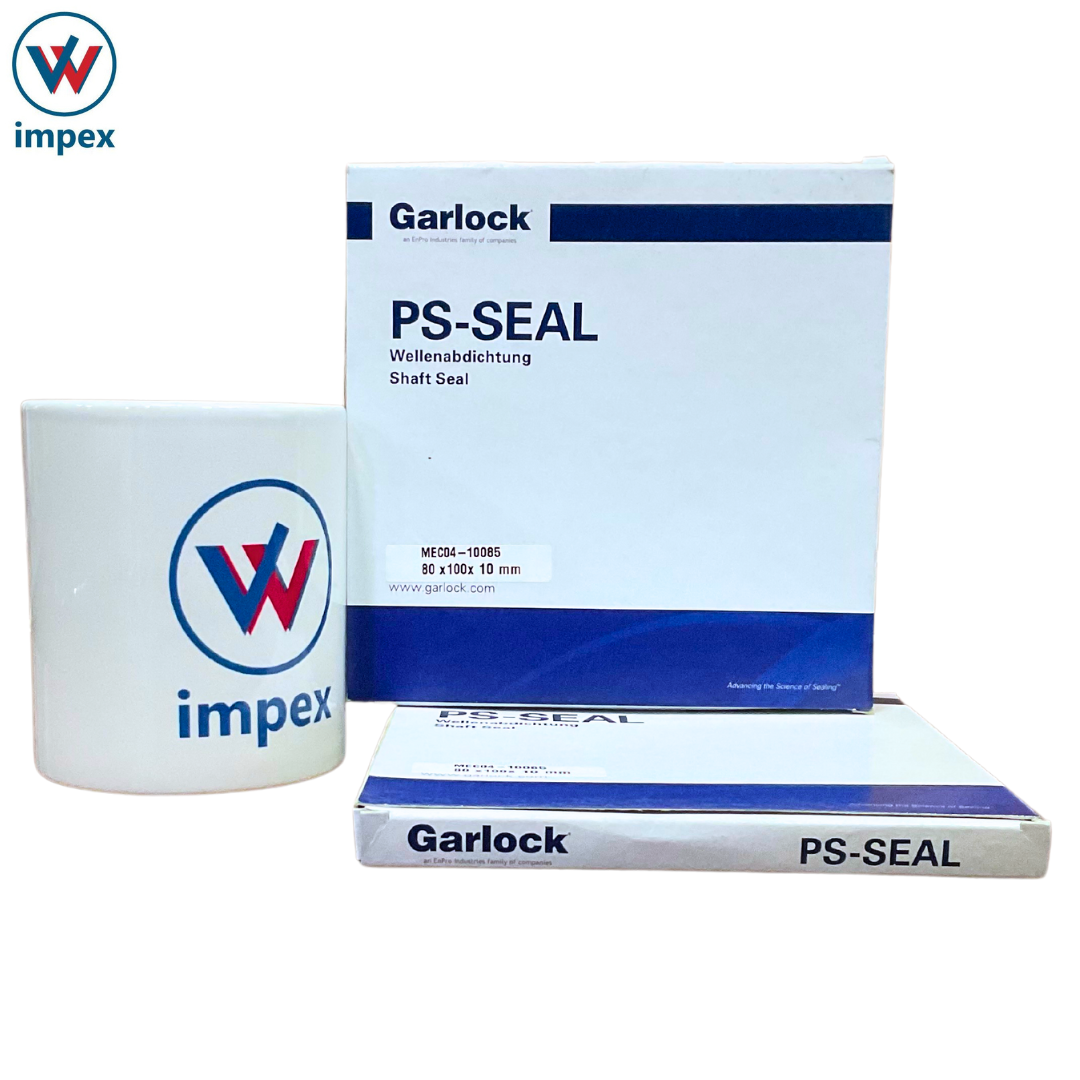

Garlock Sealing Solutions

Price 5000 INR/ Piece

Garlock Sealing Solutions Specification

- Feature

- Chemical resistant, High pressure sealing, Fire safe, Low leakage

- Hardness

- 30 - 90 Shore A

- Tolerance

- 0.1 mm

- Material

- Nitrile Rubber, EPDM, PTFE, Graphite, Silicone

- Style

- Ring Gasket, Sheet Gasket, Spiral Wound

- Shape

- Round, Rectangular, Custom

- Temperature

- -60C to 250C

- Application

- Sealing applications in oil & gas, chemical processing, power generation, food & pharma

- Color

- Black, White, Blue, Custom

- Media Compatibility

- Water, steam, oil, acids, gases

- Size Range

- 10 mm to 2000 mm

- Manufacturing Process

- Compression molded, CNC cut

- Thickness Range

- 0.5 mm to 5 mm

- Surface Finish

- Smooth, textured

- Reinforcement

- Available with metal inserts

- Pressure Rating

- Up to 1500 psi

About Garlock Sealing Solutions

Garlock offers a complete range of fluid sealing solutions, including compression packing, gasketing, hydraulic components, dynamic seals, metal gaskets and critical-service flange gaskets, plus expansion joints and high-performance metal seals.

Compression packing is rigorously tested to ensure reliable, cost-effective sealing in valves, pumps, agitators and other rotary equipment. It includes Garlock's patented 9000 EVSP valve stem packing and leading-edge DSA dry-running self-adjusting pump packing sets.

Gasketing is offered in wide range of non-asbestos materials including GYLON restructured PTFE gaskets, an industry standard for resistance to aggressive chemicals, and its extreme grade gasketing with Flange Free anti-stick coating.

Hydraulic components include heavy-duty seals to meet the demanding requirements of today's reciprocating equipment. Key products include CHEVRON V-ring packing, GARTHANE urethane seals and SLUDGE-PAKfor vertical sludge pumps. Also offered are polytop sets and turbine runner blade packing for hydroelectric applications.

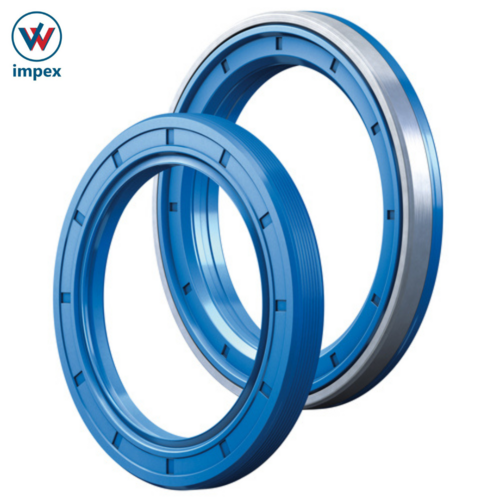

Oil seals from Garlock Klozure are available in a wide variety of configurations to meet the requirements of major industries. MILL-RIGHT materials are used on all elastomeric seals for superior bearing protection. They are available in more than 50 different styles in sizes from 1/4* to over 90*, solid or split, metal-cased or all-rubber.

Bearing isolators, also produced by Garlock Klozure, feature labyrinth design to prevent ingress of contaminants. Key products include MICRO-TEC II and GUARDIAN, both of which employ a patented cam lock design and engineered unitizing ring. These and other Klozure bearing isolators are used extensively in the chemical, pulp and paper, hydrocarbon processing, power generation and many other industries.

Mechanical seals from Garlock Klozure are available in both lip and face seal designs in four primary styles and a wide range of sizes. Key products include P/S-II lip seal, Syntron RP shaft seal, PK component seal, and GMP-I and GMP-II single and double cartridge seals. All provide sealing solutions for numerous applications in the chemical, pulp and paper, mining and power generation industries.

Metal gaskets are designed to withstand extreme temperatures, pressures and chemical exposure. Available in standard and custom configurations, these rugged metal gaskets are made of a wide range of materials to accommodate all types of process applications.

High-performance metal seals from Garlock's Helicoflex include spring-energized delta seals, C-rings and O-rings that meet high-temperature requirements, while ensuring high pressure or vacuum integrity. The company's joint development program with CEA, the French Atomic Energy Commission, supports continued innovation in these high-performance seals..

Critical-service flange gaskets from Garlock's Pikotek division include spring-energized PTFE seals and electrical flange isolation kits for cathodic protection in oil and gas production, processing, transmission, power generation and utility industries. They are approved and used by most of the world's upstream operators, pipeline companies and engineering and construction contractors.

Expansion joints are designed and engineered from a wide variety of fabric and rubber materials to absorb movement and dampen vibration, reducing stress on pumps, pipes and anchoring systems. Standard styles include the self-flushing arch of the 206EX-FLO, the industry standard 204, and the general-service 104GS. Garlock also specializes in custom configurations to meet specific system requirements.

Comprehensive Material Selection

Garlock gaskets are engineered from premium materials including Nitrile Rubber, EPDM, PTFE, Graphite, and Silicone. This extensive selection ensures compatibility with aggressive chemicals, high temperatures, and demanding pressure requirements, enhancing application flexibility and reliability across diverse industrial settings.

Precision Engineering and Customization

Each gasket is manufactured with precise tolerances (0.1 mm) and offered in sizes from 10 mm to 2000 mm. Advanced manufacturing processes, such as compression molding and CNC cutting, ensure excellent consistency, surface quality, and adaptability to specific application needs-including custom shapes, metal reinforcements, and various hardness levels.

FAQ's of Garlock Sealing Solutions:

Q: How do I select the appropriate Garlock gasket material for my application?

A: Selecting the right material depends on the specific media, pressure, temperature, and chemical exposure in your application. Nitrile Rubber is effective for oil resistance, PTFE for aggressive chemicals, EPDM for steam or water, and Graphite or Silicone for extreme temperatures.Q: What are the manufacturing processes used for Garlock sealing solutions?

A: Garlock gaskets are produced using compression molding for robust, homogeneous seals, and CNC cutting for precise, custom shapes and sizes. These methods ensure high dimensional accuracy and consistent quality across all gasket types.Q: When should metal-reinforced gaskets be chosen?

A: Metal-reinforced gaskets are recommended in demanding applications requiring enhanced mechanical strength, superior pressure handling (up to 1500 psi), or improved fire safety. This option is especially useful in oil & gas, chemical processing, and power generation environments.Q: Where can Garlock gaskets be used effectively?

A: These gaskets are extensively used in sealing applications within oil and gas, chemical industries, power plants, and food & pharmaceutical sectors due to their broad chemical compatibility and ability to withstand varied temperatures and pressures.Q: What is the benefit of having a wide size and shape range for Garlock gaskets?

A: The large selection of sizes (10 mm to 2000 mm) and availability in round, rectangular, and custom shapes ensures a precise fit in virtually any sealing assembly, reducing leaks and improving operational efficiency across many industrial processes.Q: How does surface finish impact gasket performance?

A: A smooth or textured surface finish can be selected to optimize sealing effectiveness depending on flange condition and application. Smooth finishes are ideal for tight, precision machined flanges, while textured surfaces can help seal imperfect or rough surfaces with lower gasket stress.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Rings Category

Nilos Ring

Price 500 INR / Piece

Minimum Order Quantity : 50 Pieces

Shape : Round

Tolerance : 0.05 mm

Material : Nitrile

Hardness : 6090 Shore A

SKF OIL SEALS

Price 500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Tolerance : As per DIN 3760

Material : Nitrile Rubber (NBR), Fluoroelastomer (FKM), Polyacrylate (ACM)

Hardness : 6090 Shore A

Trelleborg Oil Seal

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Shape : Round

Tolerance : 0.05 mm

Material : Nitrile Rubber (NBR)

Hardness : 70 90 Shore A

Freudenberg High Temperature Seals

Price 500 INR / Piece

Minimum Order Quantity : 5 Pieces

Shape : Circular

Tolerance : Precise dimensional tolerances

Material : Elastomer PTFE or composite materials

Hardness : Medium to high hardness range

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry