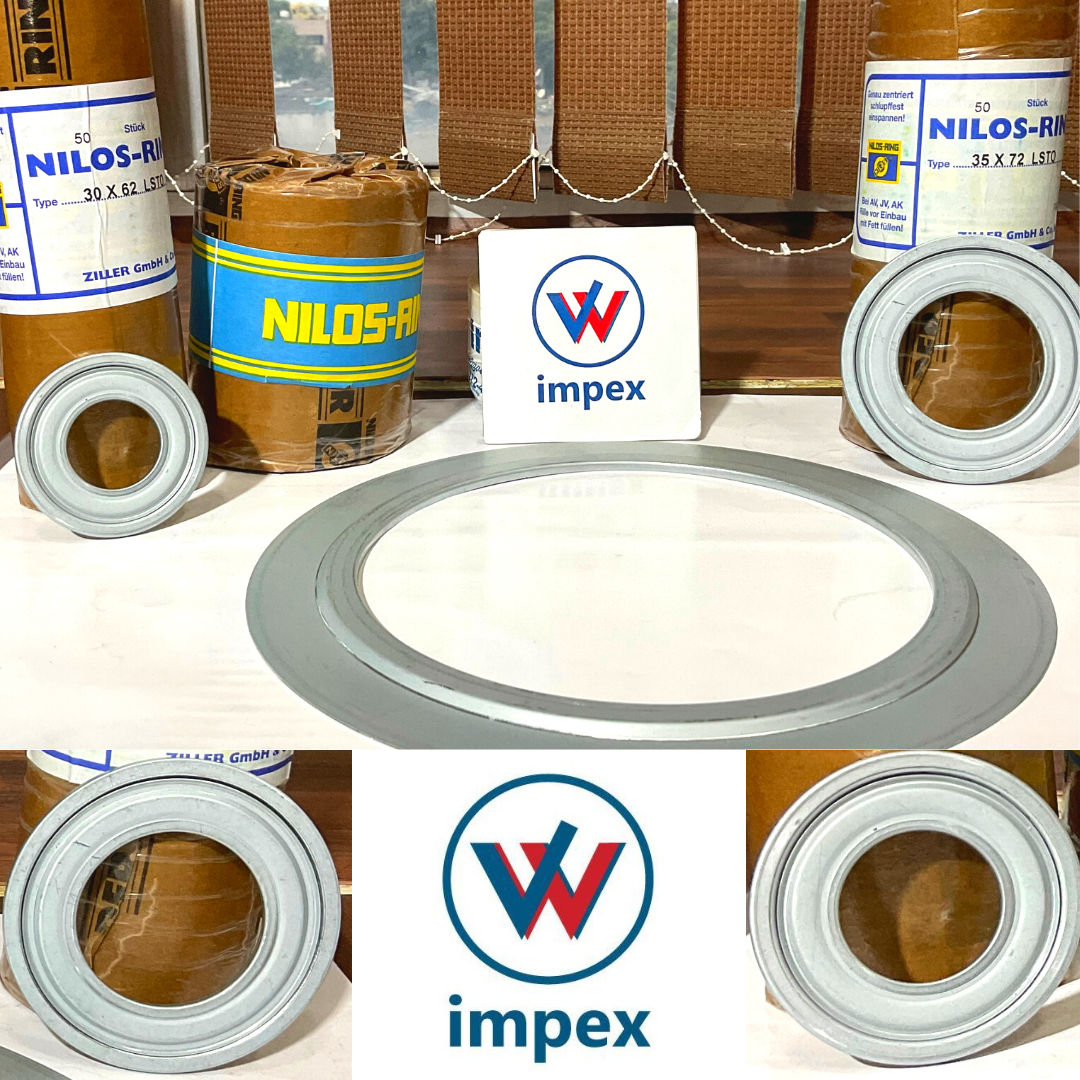

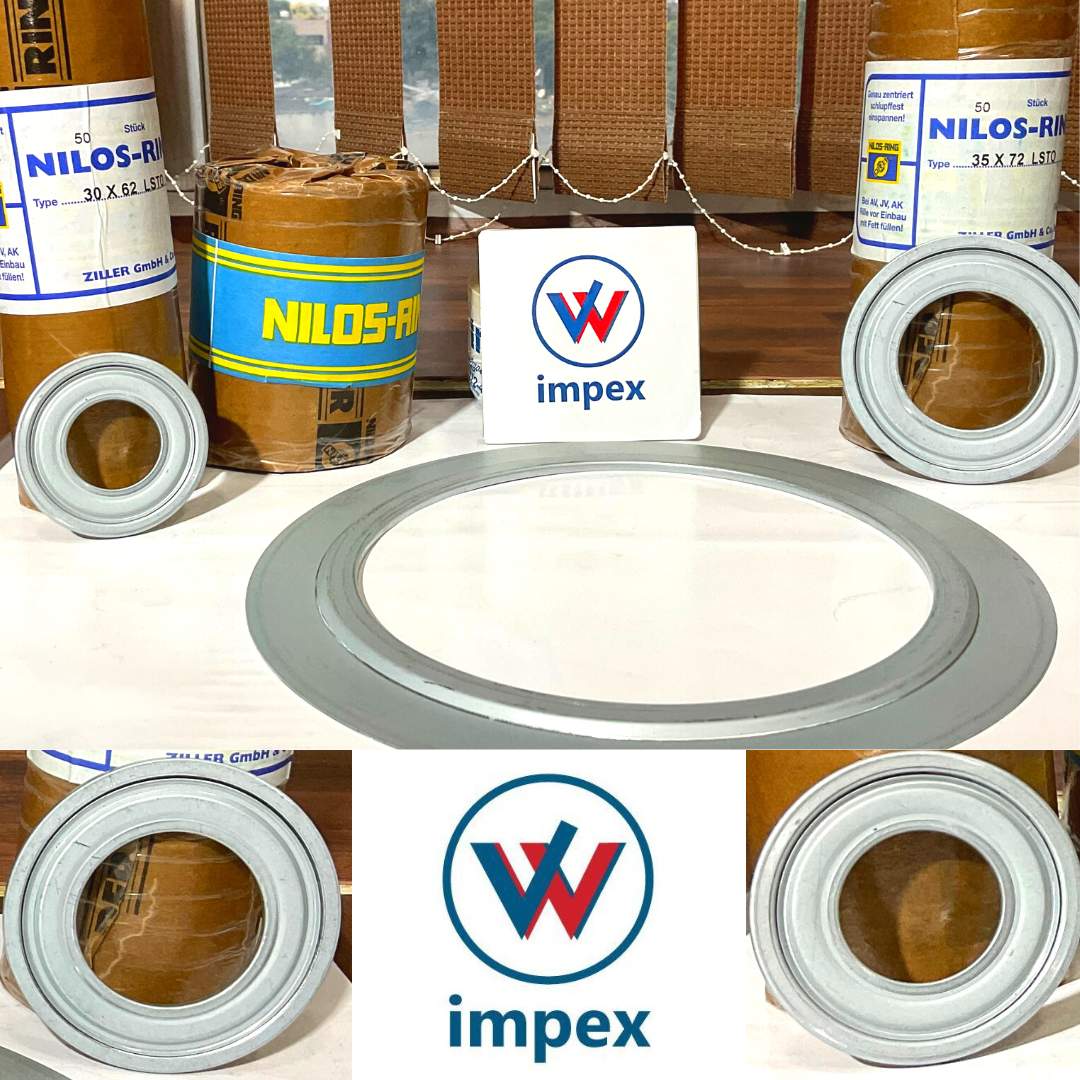

Nilos Ring

Price 500 INR/ Piece

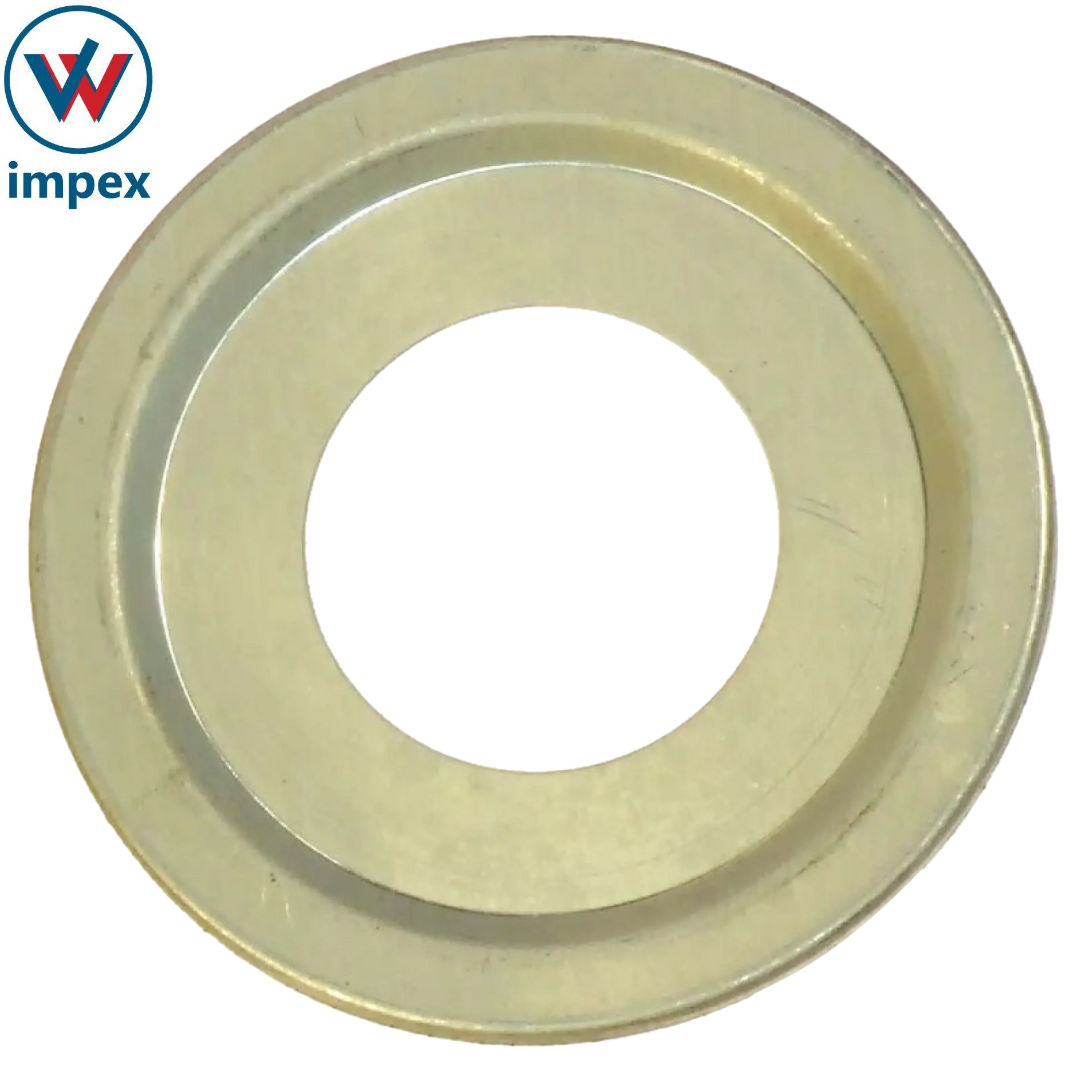

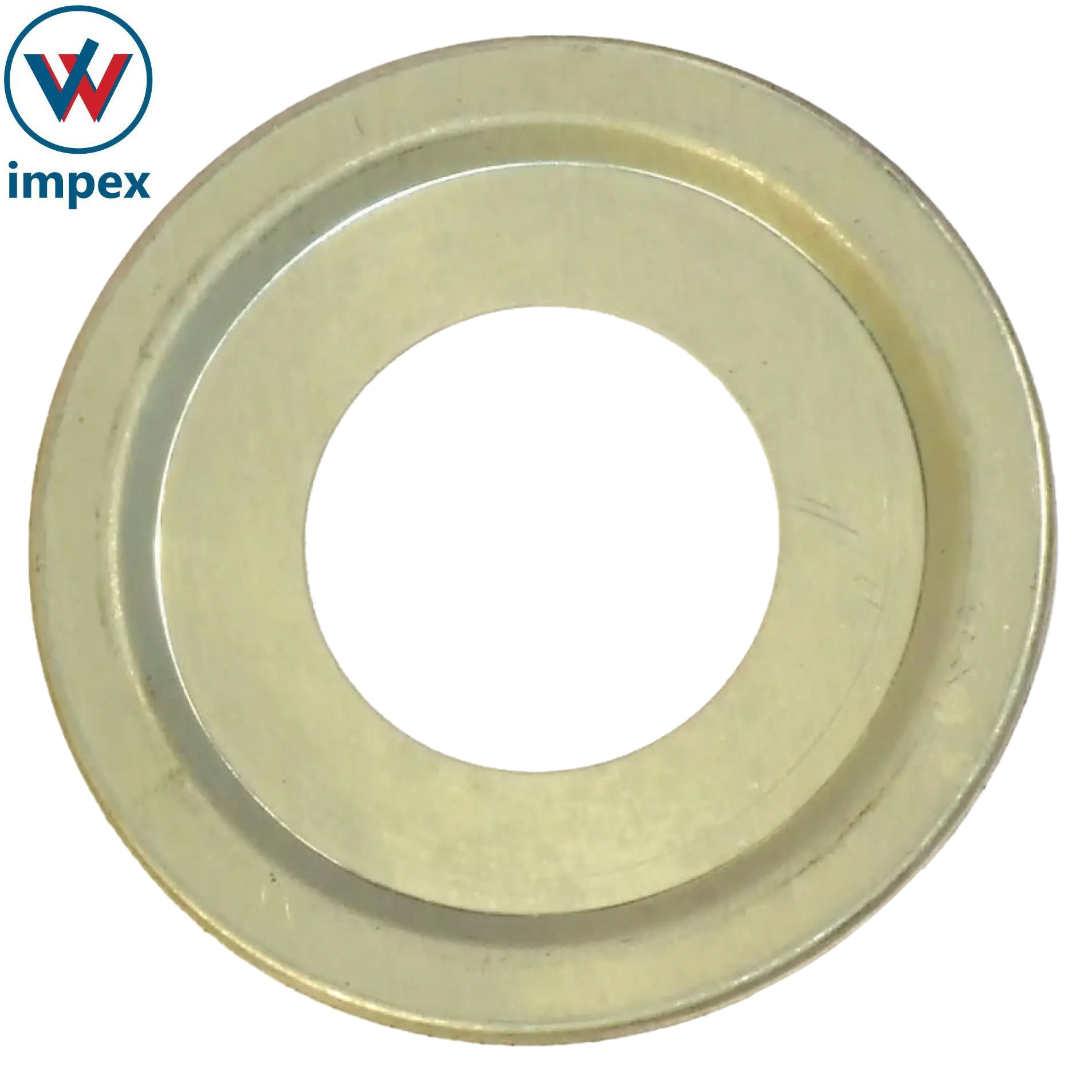

Nilos Ring Specification

- Hardness

- 60-90 Shore A

- Tolerance

- 0.05 mm

- Feature

- Prevents grease leakage and protects bearing

- Material

- Nitrile

- Style

- Standard

- Shape

- Round

- Product Type

- Nilos Ring

- Temperature

- -40C to +120C

- Color

- White

- Application

- Industrial

Nilos Ring Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- 500 Pieces Per Day

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Nilos Ring

Catering to our rich experience and understanding in this domain, our firm is involved as a leading exporter and supplier of high quality Nilos Ring. These rings are made at our vendors' fully incorporated manufacturing unit by making use of unmatched quality materials and advanced technologies in adherence with the quality norms set by the industries. We offer various sizes, shapes, diameters and dimensions in our offered range of rings to match with the variegated requirements of our wide and respected client base. The Nilos Ring is ideally used in machines and automobiles with precisely sealing the bearings.

Features:

* Light weight

* Rust resistant

* Supreme longevity

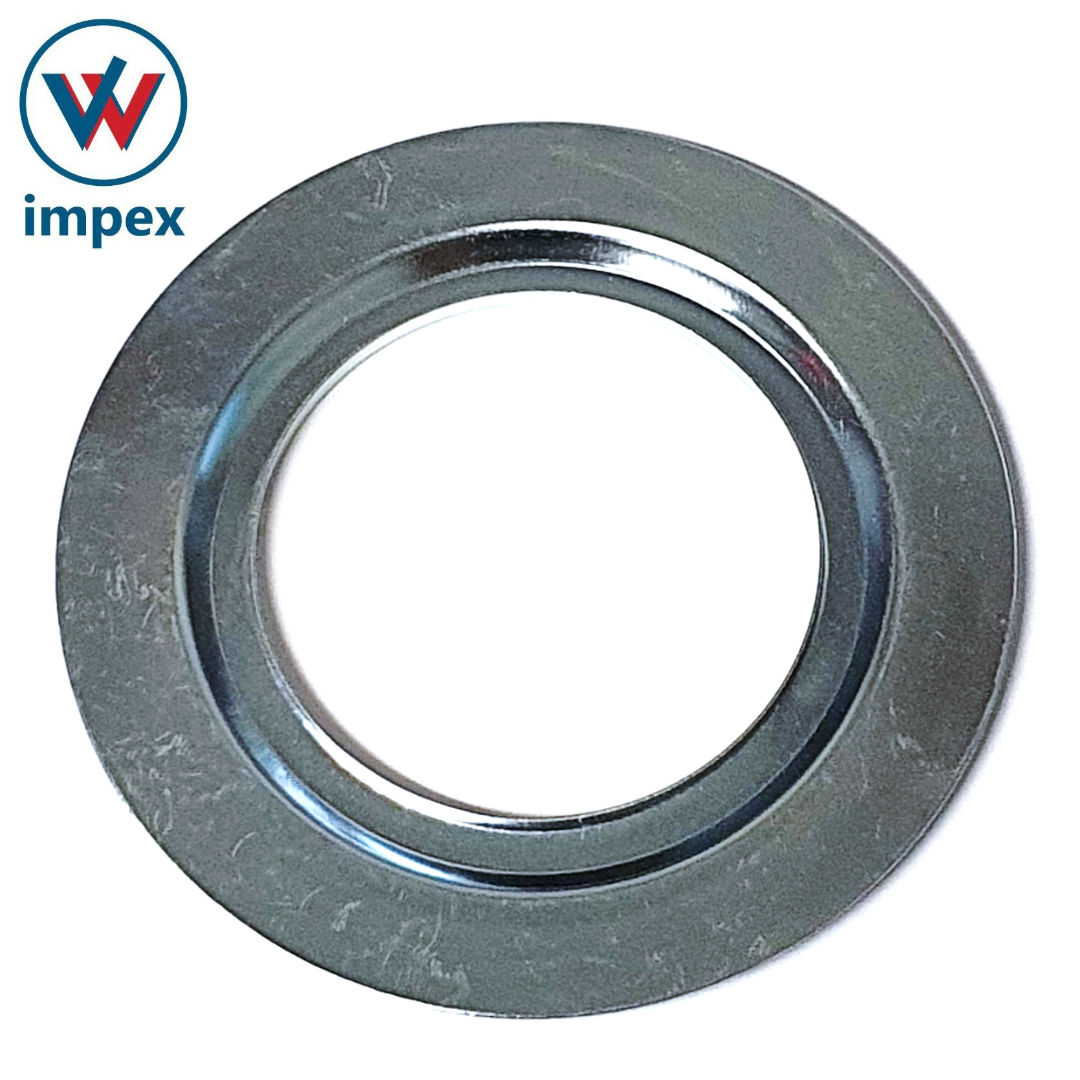

The Nilos Ring is the ideal solution for your sealing problem:

* Sturdy, low-wear metal seal for extreme application conditions.

* Can be used in virtually any existing structure due to its low overall height.

* Considerable increase in service life. Even in case of high-grade bearings with already integrated sealing. LST-L: Considerable sealing effect against liquids.

Rich kind: AV, LSTO, JV, ZAV, ZJV, AK for you chose, we only provide parts of Model No. Because of the format limits, if you are demanding some ones which are not in the list as below, please be free to contact me.

Send us your inquiry. We wil reply you soon.

Superior Material and Finish

Crafted from nitrile, the Nilos Ring combines flexibility with durability. The smooth white finish not only enhances aesthetics but also ensures efficient sealing performance against oil and wear. The high shore hardness range fits demanding industrial needs, ensuring reliability in operation.

Precision and Versatility

With strict dimensional tolerances and a standard round shape, the ring accommodates diverse industrial setups, offering compatibility with different bearing types and sizes. Its adaptability makes it favored by distributors, exporters, importers, and traders across various sectors.

FAQs of Nilos Ring:

Q: How does the Nilos Ring protect bearings in industrial applications?

A: The Nilos Ring serves as a barrier, preventing the ingress of contaminants and the escape of grease. Its excellent oil and abrasion resistance preserves the integrity and performance of bearings, extending their operational life.Q: What materials are used in the Nilos Ring, and why are they chosen?

A: The ring is made from high-quality nitrile, selected for its superior resistance to oil, abrasion, and varying temperatures. This material ensures long-term durability and reliable performance in harsh industrial conditions.Q: When should the Nilos Ring be installed on machinery?

A: It is best to install the Nilos Ring during the assembly or scheduled maintenance of bearing systems, especially when protection against grease leakage or contamination is required for optimal machinery performance.Q: Where can this Nilos Ring be sourced in India?

A: The Nilos Ring is available through authorized distributors, exporters, importers, suppliers, and traders throughout India. Contacting a reputable industrial component supplier will ensure genuine products and support.Q: What is the installation process for the Nilos Ring?

A: Typically, the ring is placed onto the bearing assembly by aligning the inner and outer diameters and gently pressing into position. Ensure correct fitment according to the specified tolerances for optimal seal performance.Q: What are the primary benefits of using the Nilos Ring in industrial settings?

A: Key benefits include effective prevention of grease leakage, enhanced bearing protection from contaminants, reduced maintenance frequency, and extended equipment life, all contributing to cost savings and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Rings Category

SKF OIL SEALS

Price 500 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Round

Style : Other, Single Lip / Double Lip

Temperature : 40C to +200C (depending on material)

Hardness : 6090 Shore A

Dichtomatik Freudenberg FST Seals

Price 1500 INR / Piece

Minimum Order Quantity : 5 Pieces

Shape : Circular / Custom

Style : Other, ORing, Rotary Shaft, Hydraulic, Pneumaticallyactuated

Temperature : 40C to +200C

Hardness : 70 to 90 Shore A

Trelleborg Oil Seal

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Shape : Round

Style : Other, Rotary Shaft Seal

Temperature : 40C to +120C

Hardness : 70 90 Shore A

TCK OIL SEALS

Price 200 INR / Piece

Minimum Order Quantity : 10 Pieces

Shape : Ringshaped

Style : Other, Rotating seal

Temperature : 30C to 200C

Hardness : 7090 Shore A

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry