Thermoplastic Bearing Units Waterproof Series

Price 3000 INR/ Piece

Thermoplastic Bearing Units Waterproof Series Specification

- Thickness

- Standardized as per series

- Weight

- Varies by model

- Material

- High-grade thermoplastic

- Ball Bearing Type

- Waterproof Series Deep Groove Ball Bearing

- Structure

- Thermoplastic housing with stainless steel insert

- Seals Type

- Dual-lip contact seals (waterproof)

- Number Of Rows

- Single Row

- Bore Size

- ALL

- Outside Diameter

- Mounted according to unit type, up to 100 mm

- Limiting Speed

- 6500 rpm

- Load Capacity

- Dynamic: 1600~5300 N, Static: 950~4000 N

- Inner Diameter

- 10 mm to 50 mm

- Temperature Range

- -20°C to +80°C

- Impact Resistance

- High, designed for rugged use

- Lubrication

- Factory-lubricated, maintenance-free

- Noise Level

- Low noise design

- Corrosion Resistance

- Excellent, suitable for wet or chemical environments

- Color

- White or custom as per requirement

- Mounting Type

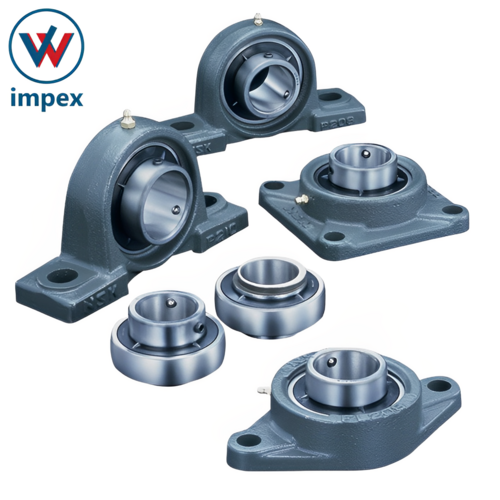

- Pillow block, flange, take-up units

- Application

- Food processing, pharmaceutical, beverage, chemical industries

- Shaft Compatibility

- Metric and inch sizes available

About Thermoplastic Bearing Units Waterproof Series

Waterproof housing :

The waterproof sealing system guarantees protection of the bearing from the external environment. Could be mounted with chrome steel insert bearings for low budget and economic application.

Special Characteristics :

Corrosion resistance,Resistance to food &liquid contaminants adapt to frequent washdowns and low weight element helps to meet your particular engineering demands.

Insert Bearings :

To be assembled with chrome steel or stainless steel insert bearings to meet your particular budget and performance needs..

| Shape | All shapes |

| Packaging Type | Single |

| Type | Mounted Units |

| Bore Size | All |

| Static Load Rating | Max |

| Housing Material | Thermoplastic |

| Basic Bearing Size | 50X143X143mm |

| Unit Weight | 1.3kg |

Unmatched Waterproof Protection

Engineered to withstand continuous exposure to water, chemicals, and moisture, these bearing units are perfect for environments where corrosion is a concern. Their thermoplastic material ensures long-lasting protection and reduces maintenance down-time, making them a reliable choice for industries with stringent hygiene and durability requirements.

Versatile Mounting and Compatibility

Available in pillow block, flange, and take-up styles, the bearing units accommodate both metric and inch shaft sizes. This versatility enables easy integration into a variety of machinery and system designs, ensuring smooth installation and enhanced operational efficiency.

Reliable Performance for Critical Applications

With high impact resistance and low noise engineering, these units are designed for rugged use in food processing, pharmaceutical, beverage, and chemical sectors. Their maintenance-free, factory-lubricated setup ensures consistent performance even in demanding, high-moisture environments.

FAQs of Thermoplastic Bearing Units Waterproof Series:

Q: How do the Thermoplastic Bearing Units Waterproof Series maintain exceptional corrosion resistance in wet and chemical environments?

A: The units are manufactured from high-quality thermoplastic materials that inherently resist corrosion, even when exposed to moisture, chemicals, or aggressive cleaning agents. This makes them ideal for industries with strict hygiene and durability specifications.Q: What mounting types are available for these bearing units?

A: The waterproof series offers various mounting options, including pillow block, flange, and take-up units. This flexibility simplifies installation across diverse machinery setups commonly found in food processing, pharmaceutical, beverage, and chemical industries.Q: When is the optimal time to use these waterproof bearing units in industrial applications?

A: These bearing units are best used when operations face frequent exposure to water, chemicals, or high humidity, such as during routine sanitation cycles or in manufacturing processes demanding corrosion resistance and low maintenance.Q: Where can I source Thermoplastic Bearing Units Waterproof Series if I am a distributor or importer?

A: This series is available through authorized suppliers, exporters, and traders in China. Whether you require bulk orders or bespoke customizations, distribution channels support a variety of business needs for international markets.Q: What is the lubrication process, and does it require maintenance?

A: Each unit is factory-lubricated and designed to be maintenance-free. This eliminates the need for regular relubrication, reducing labor costs and ensuring longer, uninterrupted operation in harsh environments.Q: How does the units impact resistance and low noise benefit my application?

A: High impact resistance allows the bearings to endure heavy loads and shocks, while their low noise design ensures quieter operation. This is particularly beneficial for sensitive environments that prioritize cleanliness and minimal disruption, such as food or pharmaceutical production.Q: Are custom colors and shaft sizes available for specific application needs?

A: Yes, the bearing units can be ordered in standard white or custom colors to match specific requirements. They are compatible with both metric and inch shafts, providing a tailored solution for various machinery and application demands.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bearing Units & Housings Category

ASAHI Bearings Japan

Price 5500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome Steel

Seals Type : Rubber Sealed

Bore Size : 20 mm to 100 mm

Inner Diameter : 20 mm 100 mm

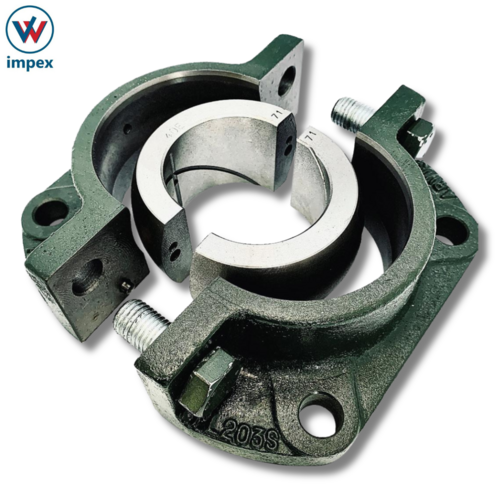

Arvis Bearing Housings

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Seals Type : Double Lip Seals

Bore Size : 20 mm to 100 mm

Inner Diameter : 20 mm

IPTCI Mounted Bearings

Price 2500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Highgrade Chrome Steel

Seals Type : Contact Seals

Bore Size : 25 mm

Inner Diameter : 25 mm

SLB Bearing Units

Price 2500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Cast Iron

Seals Type : Double Sealed

Bore Size : 25 mm

Inner Diameter : 25 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry