Call: 08045801215

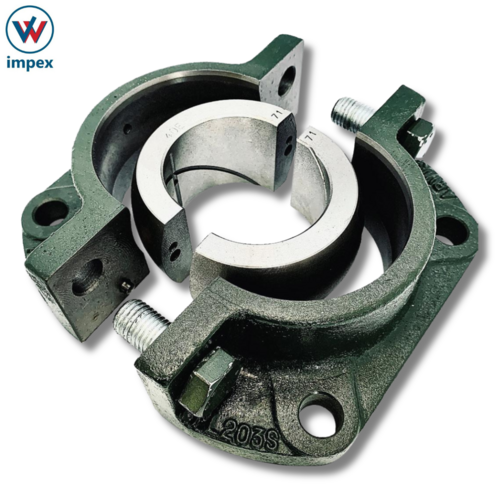

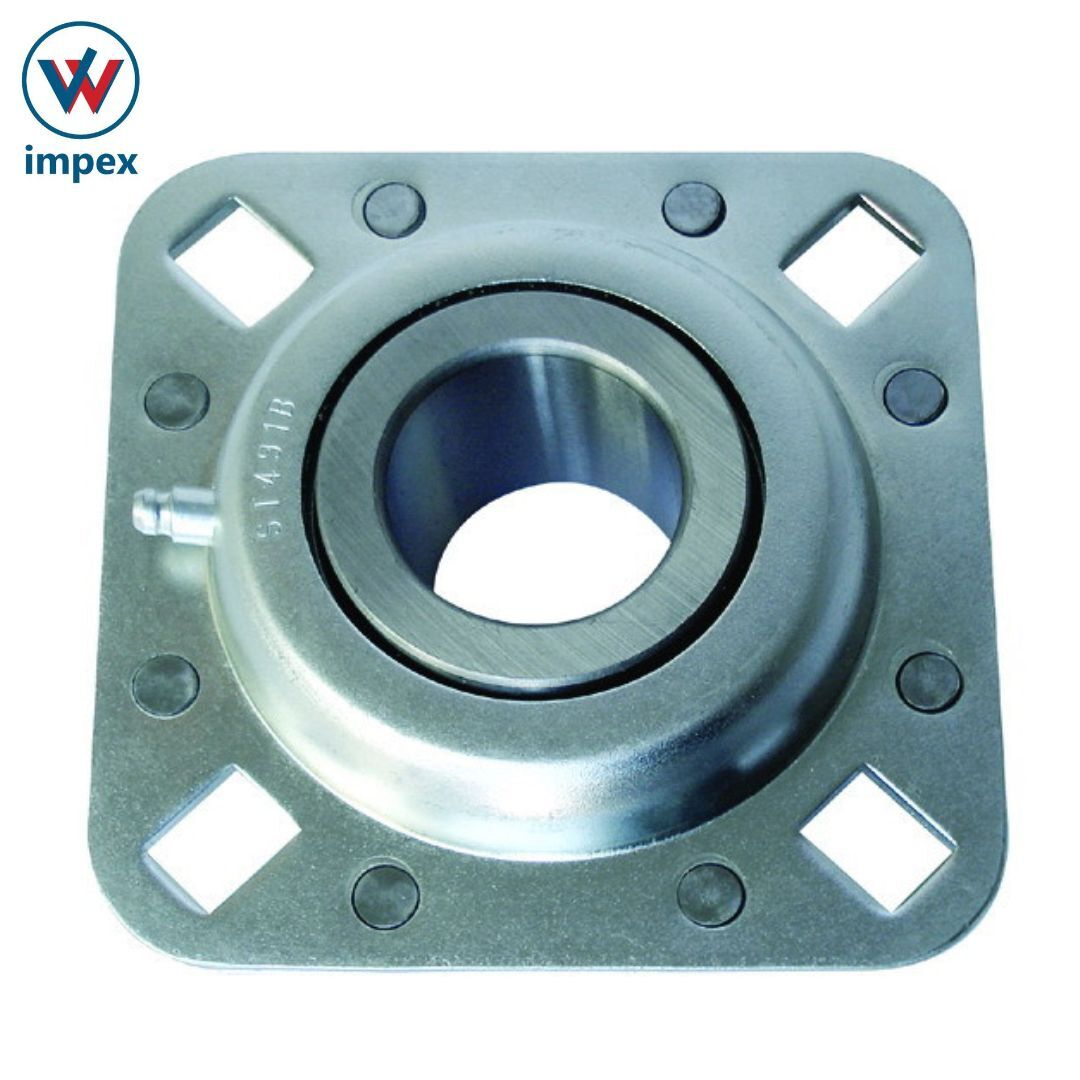

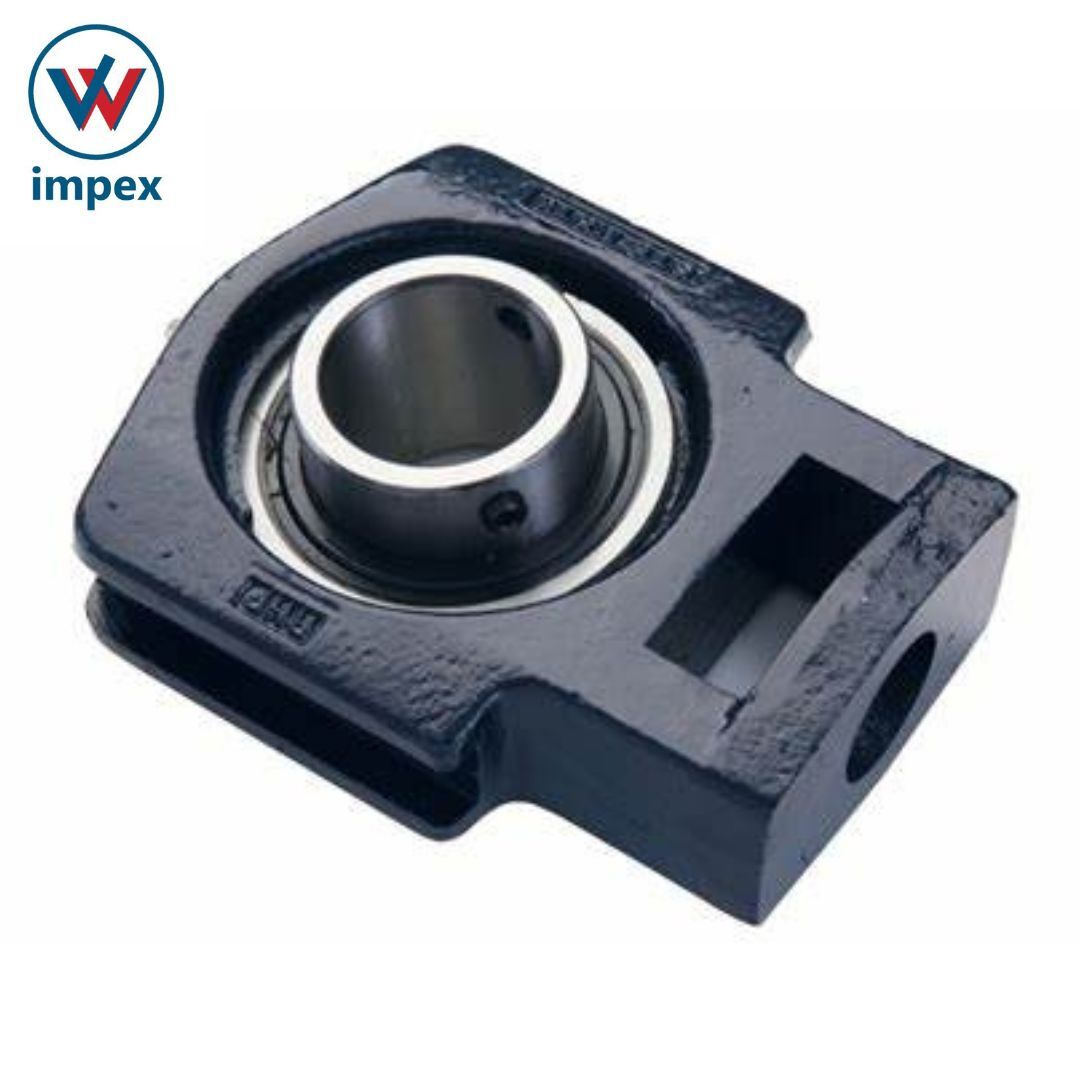

SLB Bearing Units

Price 2500 INR/ Piece

MOQ : 2 Pieces

SLB Bearing Units Specification

- Weight

- 0.6 kg

- Thickness

- 34.1 mm

- Material

- Cast Iron

- Ball Bearing Type

- Insert Ball Bearing

- Structure

- Mounting Housing

- Seals Type

- Double Sealed

- Number Of Rows

- Single Row

- Bore Size

- 25 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 5300 RPM

- Load Capacity

- Maximum 28 kN

- Inner Diameter

- 25 mm

- Mounting Type

- 2 Bolt

- Operating Temperature Range

- -20°C to 120°C

- Lubrication

- Pre-lubricated with Lithium Grease

- Corrosion Resistance

- Yes

- Application

- Conveyors, Agricultural Equipment, Textile Machinery, Mining

- ISO Certification

- ISO 9001:2015

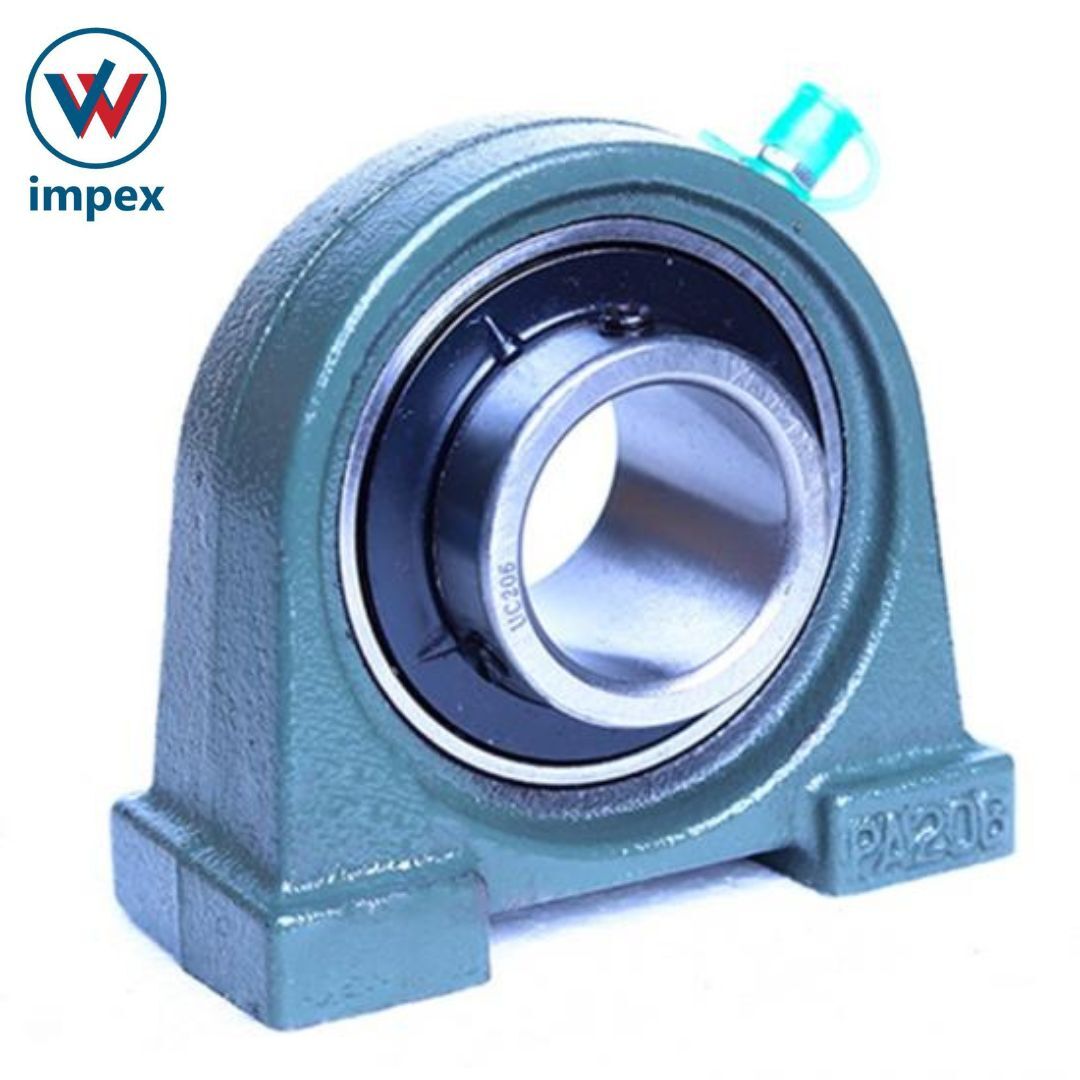

- Housing Type

- Pillow Block (UCP)

- Interchangeability

- Standardized Dimensions

- Housing Finish

- Painted

- Misalignment Tolerance

- Up to 2 Degrees

About SLB Bearing Units

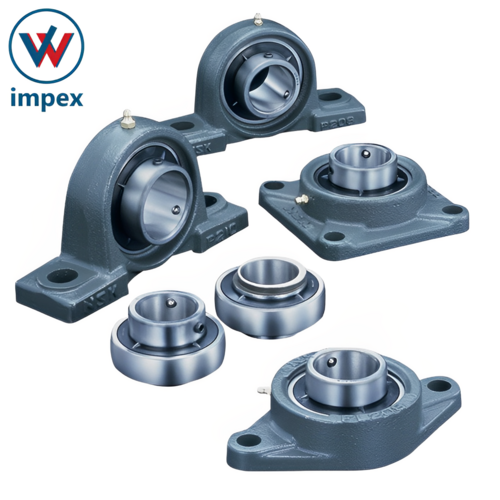

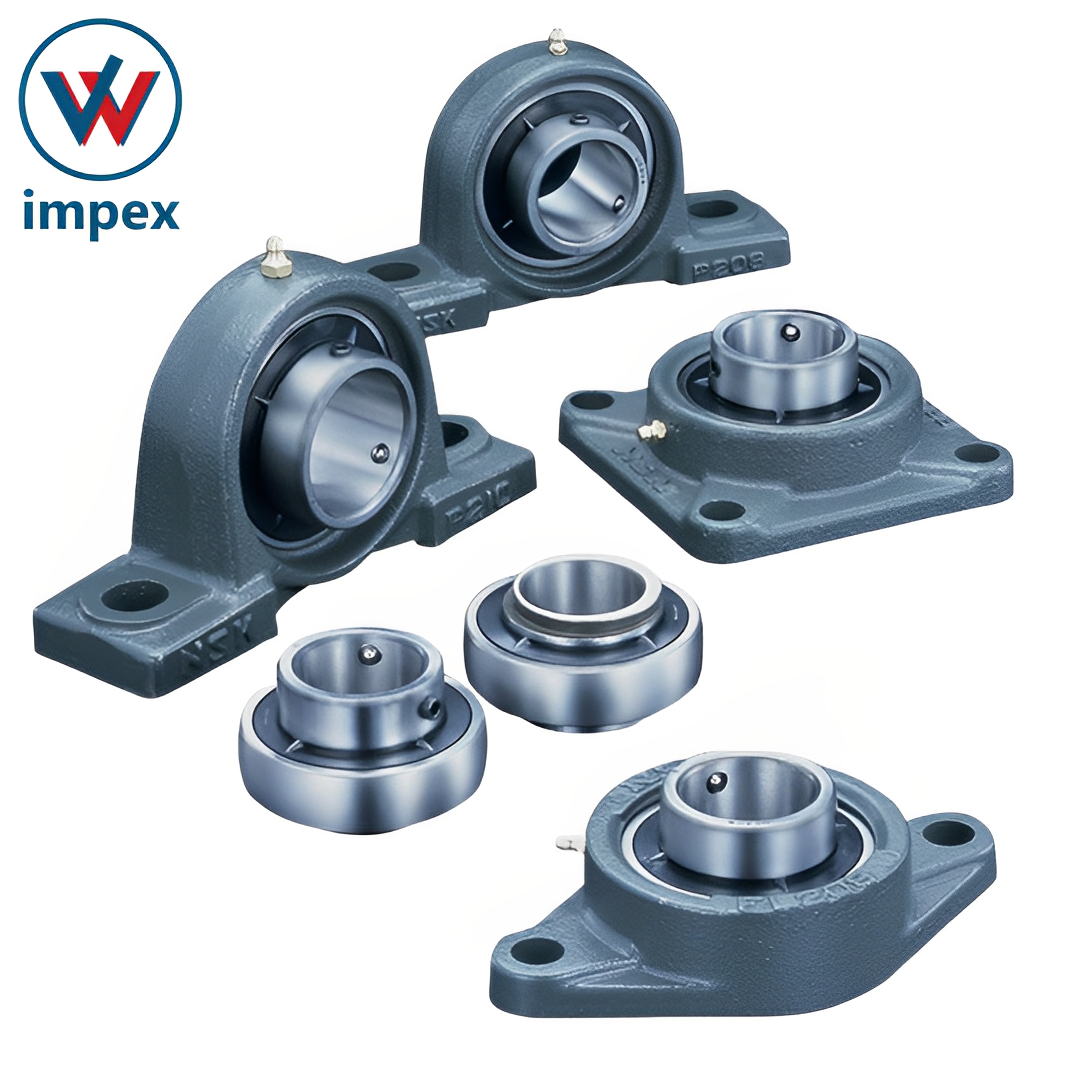

The housings are mainly casting housings. There are pressed steel plate housings as well align with ease during operation and can be conveniently mounted or dismounted. The bearing units can operate satisfactorily under working conditions, especially for machines operating in dusty or muddy surroundings. Thus, they are widely used in agricultural, construction and transmission machineries, etc...There are various types of sealing devices for our products, such as synthetic rubber seals, slinger with synthetic rubber seals and triple lip seals etc.. Sufficient lubricating grease has been put into the bearings during manufacturing, which can act as lubricating as well as rust proof. No more grease is needed to put in during the lubricating period when the bearings operate under normal conditions. Lubricating grease can be added from the fittings when the relubricate bearings operate under hard conditions. The outer ring of the bearing has spherical outside surface which can be fitted to the concave spherical surface of the housing, and the fit between them can be clearance fit or interference fit according to different conditions. This combination provides self-alignment between the self-contained bearing and the housing, and compensates for a certain alignment errors or flexing of the shaft when the bearing is in operation. This definitely increases the bearing service life.Versatile Application Range

Designed for demanding environments, SLB Pillow Block Bearing Units are ideal for conveyors, mining, agricultural, and textile machinery. Specifically engineered to tolerate variable loads and misalignment up to 2, they ensure consistent, smooth operation. Their robust construction and pre-lubrication make them suitable for settings where reliability and durability are essential, helping minimize downtime and maintenance requirements.

Certified Quality and Corrosion Resistance

These bearing units feature a painted cast iron housing and double-sealed insert bearings, ensuring excellent corrosion resistance. With ISO 9001:2015 certification, they adhere to strict quality standards, offering dependable performance in both indoor and outdoor installations. The units are pre-lubricated with lithium grease for optimal protection and longevity, enhancing their resilience in harsh industrial environments.

FAQ's of SLB Bearing Units:

Q: How do I install the SLB Pillow Block Bearing Unit with 2-bolt mounting?

A: To install, position the unit on the mounting surface, aligning the two bolt holes. Secure the unit using appropriate bolts, tightening firmly. Ensure the shaft is properly seated through the insert ball bearing, and check for correct alignment. The standardized dimensions support easy interchangeability with compatible units.Q: What benefits does the double-sealed bearing design provide?

A: The double-sealed design protects internal components from contaminants like dust, moisture, and debris, extending operational life and reducing the need for frequent maintenance. This feature ensures consistent performance in abrasive and wet environments, such as those found in agriculture or mining.Q: Where can these bearing units be used effectively?

A: SLB Pillow Block Bearing Units are suitable for a range of applications including conveyor systems, textile machinery, agricultural equipment, and mining operations. Their corrosion-resistant, robust design allows reliable function in both harsh and controlled environments.Q: When should I consider re-lubrication, given the pre-lubricated feature?

A: These units are pre-lubricated with lithium grease for immediate use; under normal operating conditions, re-lubrication is typically not required for extended periods. However, in high-speed or contaminant-heavy conditions, periodic checks are advised to ensure optimal grease levels and bearing integrity.Q: What is the misalignment tolerance of the bearing unit, and why does it matter?

A: This pillow block unit tolerates misalignments up to 2, accommodating shaft deflections and small mounting inaccuracies. This flexibility helps reduce stress on the machinery, leading to quieter, smoother operation and longer service life.Q: How does ISO 9001:2015 certification enhance confidence in this product?

A: ISO 9001:2015 certification ensures these bearing units are manufactured following strict quality management systems. Buyers can trust in their reliability, consistency, and compliance with international standards, whether sourcing as distributors, exporters, or suppliers.Q: What should I consider regarding load capacity and speed when selecting this bearing unit?

A: With a maximum load capacity of 28 kN and a limiting speed of 5300 RPM, this unit is well-suited for medium to heavy-duty tasks. Always assess your application's dynamic requirements to ensure the selected unit operates within its safe performance parameters.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Bearing Units & Housings Category

Arvis Bearing Housings

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Bore Size : 20 mm to 100 mm

Seals Type : Double Lip Seals

Limiting Speed : Up to 4000 RPM

ASAHI Bearings Japan

Price 5500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome Steel

Bore Size : 20 mm to 100 mm

Seals Type : Rubber Sealed

Limiting Speed : Up to 8500 rpm

Browning Mounted Ball Bearings Units

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Cast Iron Housing

Bore Size : 1 inch

Seals Type : DoubleSealed

Limiting Speed : 1500 RPM

SealMaster Mounted Units Roller Bearings

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : CHROME STEEL , CANVAS

Bore Size : Standard as per Catalouge

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry