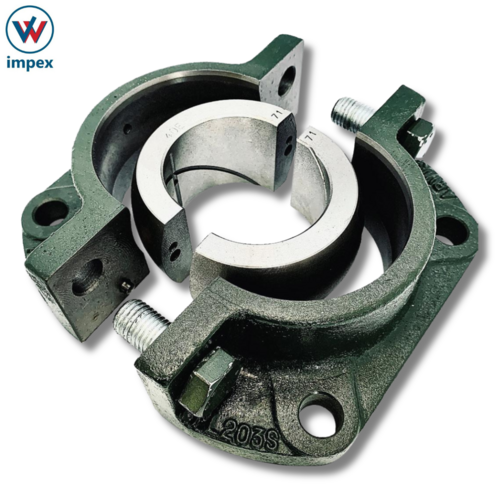

IPTCI Mounted Bearings

Price 2500 INR/ Piece

IPTCI Mounted Bearings Specification

- Weight

- 0.45 kg

- Thickness

- 18 mm

- Material

- High-grade Chrome Steel

- Ball Bearing Type

- Deep Groove Ball Bearing

- Bushes Type

- Self-lubricating

- Structure

- Four-Bolt Flange

- Seals Type

- Contact Seals

- Number Of Rows

- Single Row

- Bore Size

- 25 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 7000 RPM

- Load Capacity

- 1.1 kN

- Inner Diameter

- 25 mm

- Static Load Rating

- 1.1 kN

- Corrosion Resistance

- Yes

- Housing Material

- Cast Iron

- Temperature Range

- -20°C to 120°C

- Mounting Type

- Bolt-on

- Noise Level

- Low

- Application

- Conveyors, Agricultural Machinery, Industrial Equipment

- Interchangeability

- Standard ANSI/ABMA

- Model

- UCF205

- Dynamic Load Rating

- 1.75 kN

- Lubrication

- Pre-lubricated with Grease

About IPTCI Mounted Bearings

IPTCIis a manufacturer of standard and corrosion-resistant (washdown) mounted bearings. Their standard mounted bearings feature rigid construction and are available in both set screw and eccentric locking collar. Bore sizes range from 1/2 to 4 in. IPTCI corrosion resistant bearings for washdown applications include nickel plated, stainless steel, black oxide, or chrome coated units.

Their complete line of mounted bearings combines quality, innovation and affordability to give you the advantage you need. Their advantage-focused service means providing our customers with an edge over their competition. Whatever your mounted bearing needs, put our advantage-focus to work for you.

IPTCI'snew IP69K Series bearings are proven to perform in close-range, high-temperature caustic washdowns. Now available on IPTCI Corrosion Resistant Bearings.

Whether your bearing needs are light, standard or medium duty, IPTCI offers the widest variety of choices for your specific requirements. Covering a range of 1/2" to 4" bore, all IPTCI mounted bearings feature rigid construction and are available in both set screw and eccentric locking collar.

- Pillow Blocks

- 4 Bolt Flanges

- 2 Bolt Flanges

- 3 Bolt Flange Brackets

- Tapped Base Pillow Blocks

- Hanger Units

- Take Up Units

- 4 Bolt Piloted Flanges

- 3 Bolt Flanges

- Bearing Inserts

- Corrosion Resistant Products

- Standoff Products

Reliable and Versatile Performance

Designed for longevity and efficiency, the UCF205 bearing delivers steady performance even in demanding commercial and industrial environments. Its ability to resist corrosion and operate quietly supports a wide range of machinery, providing confidence in both indoor and outdoor usage.

Easy Installation and Maintenance

With a bolt-on, four-flange structure and pre-lubricated bearings, installation is straightforward, saving time and resources during setup. Standard ANSI/ABMA interchangeability ensures quick sourcing and replacement, keeping operations running smoothly.

Engineered for Heavy Loads and Speed

The high-grade chrome steel and deep groove ball design allow the bearing to handle dynamic loads up to 1.75 kN and speeds up to 7000 RPM. This makes it suitable for high-performance machinery, maximizing operational uptime and reliability.

FAQ's of IPTCI Mounted Bearings:

Q: How should the IPTCI UCF205 mounted bearing be installed?

A: The UCF205 bearing should be secured using the four-bolt flange directly onto a mounting surface, ensuring alignment with the shaft. Its bolt-on design streamlines installation and offers stability, making it suitable for various machines and equipment.Q: What are the main benefits of using this cast iron housed bearing in industrial equipment?

A: This bearing offers a rugged cast iron housing, low noise levels, corrosion resistance, and pre-lubricated self-lubricating bushes, ensuring reliability, longer service life, and less frequent maintenance for industrial and agricultural machinery.Q: When should the bearing be relubricated or inspected?

A: Although the UCF205 comes pre-lubricated, it is advisable to inspect and relubricate according to the equipment's operating conditions. For most industrial uses, inspection every 6-12 months suffices, but harsh environments may require more frequent checks.Q: Where can the UCF205 mounted bearing be used most effectively?

A: This bearing is engineered for conveyors, agricultural machinery, and a spectrum of industrial applications, excelling in environments that demand dependable load handling, corrosion resistance, and consistent operational speed.Q: What process ensures the bearing's corrosion resistance?

A: The UCF205 features a corrosion-resistant coating on its cast iron housing and high-grade chrome steel internals, making it suitable for applications where exposure to moisture, chemicals, or fluctuating conditions is common.Q: How does the ANSI/ABMA interchangeability standard benefit users?

A: Standard ANSI/ABMA interchangeability means the bearing can be easily replaced or sourced without compatibility concerns, reducing downtime for distributors, exporters, suppliers, and end-users.Q: What kind of maintenance is required for the IPTCI UCF205 bearing?

A: Routine maintenance involves periodic inspection and reapplication of lubricant if needed, as well as checking the seals and mounting bolts to ensure optimal performance and longevity.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bearing Units & Housings Category

ASAHI Bearings Japan

Price 5500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome Steel

Seals Type : Rubber Sealed

Bore Size : 20 mm to 100 mm

Inner Diameter : 20 mm 100 mm

Arvis Bearing Housings

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Seals Type : Double Lip Seals

Bore Size : 20 mm to 100 mm

Inner Diameter : 20 mm

Hub City Bearing Units

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Cast Iron

Seals Type : Synthetic Rubber Seals

Bore Size : 20 mm

Inner Diameter : 20 mm

SKF ConCentra Roller Bearing Units

Price 12000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Bearing steel

Seals Type : SKF triplelip labyrinth seal

Bore Size : 40 mm to 100 mm (standard)

Inner Diameter : 40 mm to 100 mm (standard)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry