Steinel Guide Units

Price 15000 INR/ Piece

Steinel Guide Units Specification

- Thickness

- 3 mm - 20 mm

- Weight

- From 0.2 kg to 10 kg

- Material

- Alloy Steel / Hardened Steel

- Ball Bearing Type

- Precision Ball Bearing

- Roller Bearing Type

- Needle Roller Bearing

- Bushes Type

- Self-Lubricating Bronze Bush

- Structure

- Guide Pillar & Bush Assembly

- Seals Type

- Nitrile Rubber Seals

- Number Of Rows

- Single / Double Row

- Bore Size

- 8 mm to 80 mm

- Outside Diameter

- 16 mm - 100 mm

- Limiting Speed

- 6000 rpm

- Load Capacity

- Up to 150 kN

- Inner Diameter

- 8 mm - 80 mm

- Hardness

- 58-62 HRC

- Operating Temperature

- -20°C to +120°C

- Application

- Die and Mould Base Alignment

- Shaft Type

- Cylindrical / Stepped

- Tolerance

- ISO H7/H8

- Standard

- DIN / ISO Specification

- Corrosion Resistance

- Yes

- Customisation

- Available on Request

- Mounting Type

- Press Fit / Slip Fit

- Surface Finish

- Precision Ground With Hard Chrome Plating

About Steinel Guide Units

In 1925, Bernhard Steinel founded Bernhard Steinel Werkzeugmaschinenfabrik GmbH & Co. KG the cornerstone of a successful business. Both nationally and internationally, the name STEINEL quickly became synonymous with quality. STEINEL evolved from a supplier of standard parts to a systems provider.

STEINEL, a family-owned business with production facilities in Villingen-Schwenningen and Halblech/Buching, stands for top precision and offers high-quality punching and bending technology as well as mechanical engineering solutions.

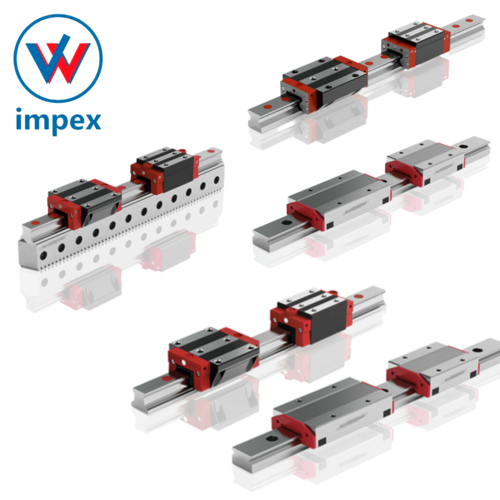

Guide Units

Our high-precision, durable guide units are designed for universal use in tool shops and the fields of machine engineering, measuring device design, apparatus engineering and fixture construction. In addition to our large range of standard guide units, our customer-specific guide units make it possible to implement tailor-made solutions optimally, quickly and economically with maximum quality and extended lifetime guaranteed.

Quality criteria of STEINEL guides

Outstanding lifetimes and high loading capacity due to: highest part precision

Outstanding surface quality

Optimum material selection

Tailored heat treatment process

Perfect matching

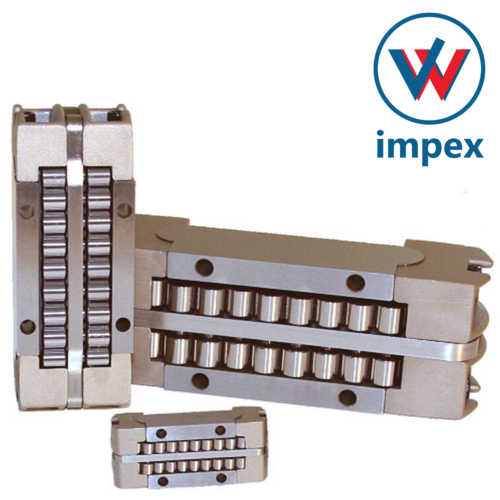

Sliding Guides

For a wide range of application fields, including in dirty (contaminated) environments with high lateral forces, in the versions with bronze coating or solid lubricant.

Roller Guides (Roller & Ball Guides)

Intended for preloaded guide units that are free of clearance. Standardised and available in diameters from 3 mm to 80 mm. Ball cages made of plastic, aluminium or brass, aluminium roller cages.

Quality criteria of STEINEL Roller Guides

Long life time Profile rollers and balls are helically arranged in the cage, and are free-wheeling mounted.

Fast stroke movements Speeds of up to 30 m/min. can be achieved as a result of the low friction of the rollers or balls.

High lateral forces possible The large number of load-bearing rollers or balls ensures an even force distribution.

High guide accuracy and interchangeability Profile rollers or balls of optimum precision and identical sorting are used.

Low maintenance expense

Guide Pillars

A wide range of standardised guide pillars with diameters from 3 mm to 100 mm, that can be used with sliding guide bushes and roller guides.

High-Precision Construction

Steinel Guide Units are meticulously crafted with precision ground surfaces and hard chrome plating, ensuring superior wear resistance and minimized friction. This meticulous attention to surface finish enhances the alignment accuracy essential for die and mould base applications, supporting consistent performance even in high-cycle operations.

Exceptional Load and Speed Capabilities

Designed to withstand demanding manufacturing environments, Steinel Guide Units accommodate substantial loads up to 150 kN and reach limiting speeds of 6000 rpm. The integration of precision ball and needle roller bearings ensures reliable motion, while nitrile rubber seals protect internal components for longer service life.

Customisation and Versatile Applications

Whether you require a standard or tailored solution, these guide units can be customized for unique specifications. Their compatibility with multiple mounting and shaft types, as well as single or double row configurations, makes them versatile for various die and mould assembly requirements. Sourcing options include distributor, exporter, importer, supplier, and trader channels, primarily from Germany.

FAQ's of Steinel Guide Units:

Q: How do Steinel Guide Units ensure precise alignment in die and mould bases?

A: The units utilize a precision ground surface with hard chrome plating, combined with tight ISO H7/H8 tolerances and a robust guide pillar and bush assembly. This construction guarantees stable, accurate alignment during high-precision operations.Q: What are the benefits of hard chrome plating on the guide units?

A: Hard chrome plating provides enhanced corrosion resistance and wear protection, prolonging service life and maintaining performance consistency, especially in demanding manufacturing environments.Q: When should you opt for single or double row Steinel Guide Units?

A: Single row configurations are ideal for lighter loads and compact assemblies, whereas double row units should be chosen for heavier load applications where greater stability and alignment precision are required.Q: Where can Steinel Guide Units be sourced or supplied?

A: These guide units are distributed, exported, imported, and supplied by authorized channels globally, with Germany being the primary source for genuine products and customisation options.Q: What is the recommended process for mounting the guide units?

A: Steinel Guide Units are available for both press fit and slip fit mounting types. Choose the appropriate method based on your assembly design and follow the standard procedure to ensure a secure, precise fit.Q: How do the bearing and bush options improve the guide unit's performance?

A: Precision ball bearings and needle roller bearings provide smooth rotational movement, while self-lubricating bronze bushes minimize maintenance needs. This combination enhances operational efficiency and extends the unit's functional lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Linear Motion Category

Schneeberger Linear Guide

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Other, 2

Material : Highquality Steel

Weight : 1.5 kg/m

Inner Diameter : 16 mm

Shuton Precision Ball Screws

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Other, Multiple (Depends on Model)

Material : Alloy Steel, Hardened and Ground

Weight : Depends on Size and Model

Inner Diameter : 16 mm to 80 mm

Tychoway Linear Roller Bearings

Price 25000 INR

Minimum Order Quantity : 1 Piece

Number Of Rows : Single Row

Material : Alloy Steel

Weight : 0.15 kg

Inner Diameter : 12 mm

Ball Spline For SLF OR SLT Type

Price 20000-30000 INR

Minimum Order Quantity : 1 Piece

Number Of Rows : Other, 2 or 4 Rows

Material : High Carbon Chromium Bearing Steel

Weight : 0.12 kg to 2.8 kg

Inner Diameter : 6 mm to 40 mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry