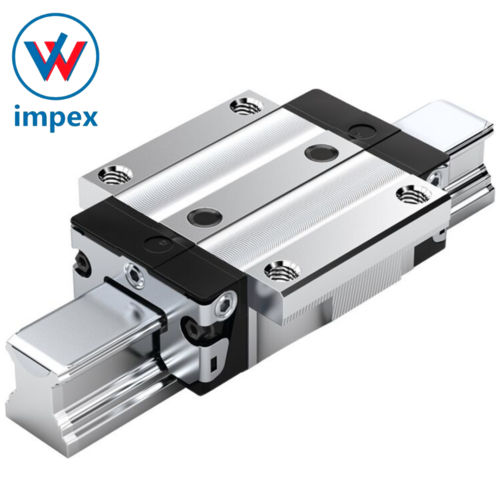

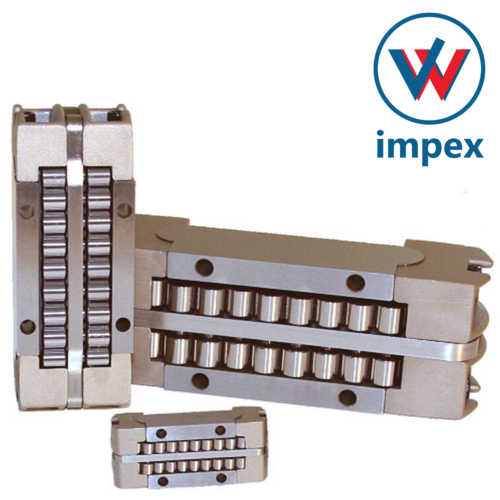

Tychoway Linear Roller Bearings

Tychoway Linear Roller Bearings Specification

- Weight

- 0.15 kg

- Thickness

- 10 mm

- Material

- Alloy Steel

- Ball Bearing Type

- Linear

- Roller Bearing Type

- Cylindrical Roller

- Bushes Type

- Sliding Bearing

- Structure

- Supported Rail

- Seals Type

- Double Sealed

- Number Of Rows

- Single Row

- Bore Size

- 12 mm

- Outside Diameter

- 25 mm

- Limiting Speed

- 8000 RPM

- Load Capacity

- 2000 N

- Inner Diameter

- 12 mm

About Tychoway Linear Roller Bearings

The extremely low friction of Tycho way Linear Roller Bearings enables them to provide very accurate positioning in machine slides by virtually eliminating the stick-slip phenomenon. The combination of positioning and travel accuracy benefits afforded by Tycho way Linear roller Bearings meet the worlds toughest competition.Tycho way recirculating Linear Roller Bearings provide predictable, repeatable positioning accuracy with minimum service requirements. A diverse range of sizes allows use in applications from compact diesto large machine tools. Tycho way Bearings have static load capacities rated from 4,330 to 122,000lbs. The smallest bearing, only 0.56 inches wide, can be mounted in very compact assemblies. Larger sizes are used in machine tools, paper.

Precision and Durability in Linear Motion

Tychoway Linear Roller Bearings combine a rust-proof coated alloy steel body and a hardened steel guide rail, providing exceptional resistance against wear and corrosion. Their double-sealed, pre-lubricated design ensures sustained accuracy even under challenging environmental conditions. These attributes make them ideal for precision motion machinery where long service life and consistent reliability are paramount.

Engineered for Versatile Applications

With a cylindrical roller bearing type and single-row structure, these linear bearings are tailored for systems that require smooth, high-speed linear motion. Their 12 mm bore and 8000 RPM limiting speed accommodate various engineering setups, offering flexibility for machinery in manufacturing, automation, and other precision-driven sectors.

FAQs of Tychoway Linear Roller Bearings:

Q: How are Tychoway Linear Roller Bearings typically installed in machinery?

A: Tychoway Linear Roller Bearings are designed with a bolt mount structure, allowing for secure, easy installation onto supported rails. This setup ensures correct alignment with precision motion systems and minimizes movement, which is crucial for maintaining repeatable accuracy in high-performance machinery.Q: What makes the hardened steel guide rail advantageous in industrial applications?

A: The use of a hardened steel guide rail significantly increases the wear resistance and longevity of the bearing assembly. This material choice provides a stable, tough tracking surface, supporting smooth and consistent linear motion even in environments subjected to constant operation or vibration.Q: When is it necessary to re-lubricate these pre-lubricated bearings?

A: Tychoway Linear Roller Bearings come pre-lubricated and feature a double-sealed design, which reduces maintenance requirements significantly. However, in extremely demanding or contaminated environments, periodic inspection and lubrication may be recommended as per equipment manufacturer guidelines to maximize service life.Q: Where are these bearings most commonly used?

A: These linear roller bearings are commonly employed in precision motion machinery such as CNC machines, automation systems, and high-speed industrial equipment. Their robust construction makes them suitable for various sectors, including manufacturing, electronics, and automotive industries.Q: What is the benefit of the rust-proof coating on the bearing surfaces?

A: The rust-proof coated finish adds an extra layer of protection against environmental moisture and corrosive particles. This feature ensures a longer operational lifetime and sustained performance, even when the bearings are exposed to humid or adverse atmospheric conditions.Q: How does the single-row cylindrical roller structure influence performance?

A: The single-row cylindrical roller structure offers a balance between high load-carrying capacity and minimized friction. This design delivers reliable guidance for linear motion, which is essential for applications demanding both precision and efficiency in load management.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Linear Motion Category

Steinel Guide Units

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Alloy Steel / Hardened Steel

Number Of Rows : Other, Single / Double Row

Outside Diameter : 16 mm 100 mm

Limiting Speed : 6000 rpm

Ewellix Linear Guides

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Stainless Steel

Number Of Rows : Other, 2

Outside Diameter : 16 mm

Limiting Speed : 3 m/s

NB Linear Bearing

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome Steel, Stainless Steel

Number Of Rows : Other, Multiple Rows

Outside Diameter : 15 mm to 80 mm

Limiting Speed : Up to 5000 rpm

Rexroth Linear Motion Guide Way

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry