Call: 08045801215

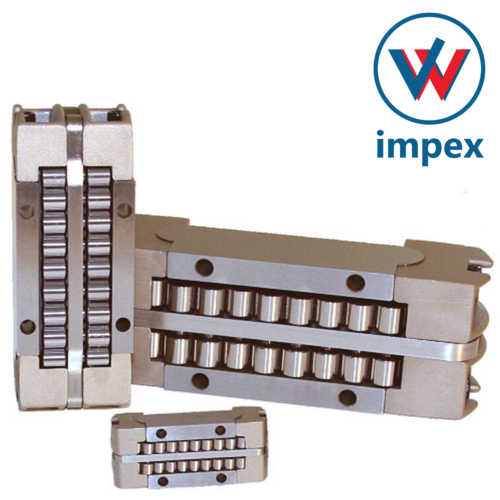

Shuton Precision Ball Screws

Price 15000 INR/ Piece

MOQ : 1 Piece

Shuton Precision Ball Screws Specification

- Weight

- Depends on Size and Model

- Thickness

- As per model specification

- Material

- Alloy Steel, Hardened and Ground

- Ball Bearing Type

- Precision Ground Ball Bearing

- Bushes Type

- Polymer Bushes

- Structure

- Single Nut, Double Nut

- Seals Type

- Labyrinth and Wiper Seals

- Number Of Rows

- Multiple (Depends on Model)

- Bore Size

- Standard and Customized Sizes Available

- Outside Diameter

- Customized per application

- Limiting Speed

- Up to 6000 RPM

- Load Capacity

- High Dynamic and Static Loads (consult catalogue)

- Inner Diameter

- 16 mm to 80 mm

About Shuton Precision Ball Screws

Shuton Precision Ball Screws

Shuton is a leading company in the design and manufacture of high performance ball screws located in the Country, central focus and leader of the machine tool industry.

SHUTON preloaded compact nut ball screws offer many advantages:

PRIME preloaded compact nut ball screw is designed with internal ball recirculation system 'S'. This is the normal recirculation for shorter leads. Each ball circuit is independent, and has its own S-shaped deflector.

The nut in double nut ball screws is comprised of two parts separated by a washer, the thickness of which determines the preload force.

At SHUTON these two parts are embedded, in order to eliminate potential radial displacement and improve the alignment and concentricity of both parts.

Double nut ball screw maintenance is very rapid, as it does not need to be dismounted from the machine.

COMPLEX double nut ball screw is designed with U external ball recirculation system, normally used for short lead Ph<20. Ball return is done via a recirculating tube assisted solely by two shaped deflectors.

Additional Information:

Shuton is a leading company in the design and manufacture of high performance ball screws located in the Country, central focus and leader of the machine tool industry.

SHUTON preloaded compact nut ball screws offer many advantages:

- Better alignment and concentricity of the whole nut with the screw.

- Reduced nut length, thus less mass.

- Elimination of the bearing holder parts in rotary nut designs.

- Possibility of special designs, with compact nut-carrying bodies.

PRIME preloaded compact nut ball screw is designed with internal ball recirculation system 'S'. This is the normal recirculation for shorter leads. Each ball circuit is independent, and has its own S-shaped deflector.

The nut in double nut ball screws is comprised of two parts separated by a washer, the thickness of which determines the preload force.

At SHUTON these two parts are embedded, in order to eliminate potential radial displacement and improve the alignment and concentricity of both parts.

Double nut ball screw maintenance is very rapid, as it does not need to be dismounted from the machine.

COMPLEX double nut ball screw is designed with U external ball recirculation system, normally used for short lead Ph<20. Ball return is done via a recirculating tube assisted solely by two shaped deflectors.

Additional Information:

- Item Code: Shuton Ball screws

- Minimum Order Quantity: 1 pcs

Exceptional Precision and Durability

Shuton Precision Ball Screws provide lead accuracy down to 0.005 mm/300 mm and incorporate robust, hardened raceways. Multiple preload and nut configurationssingle or doublemake them adaptable for projects demanding utmost control, reliability, and low maintenance in challenging industrial settings.

Flexible Applications and Customization

Designed to suit CNC machinery, robotics, automation, and machine tools, Shuton Ball Screws support strokes up to 6000 mm, custom diameters (ID 16 mm to 80 mm), and dynamic/static load ratings tailored as per application. Configurable bore sizes and mounting options ensure seamless integration.

User-Oriented Design for Optimized Performance

With polymer bushes, precision bearings, and dual seal options, these ball screws minimize friction, resist contamination, and handle high rotational speeds up to 6000 rpm. Suitable for use in diverse environments, they maintain stability and longevity across a wide temperature range (-10C to +80C).

FAQs of Shuton Precision Ball Screws:

Q: How do I select the right preload type for my application using Shuton Precision Ball Screws?

A: Preload selection depends on your rigidity and backlash requirements. Light preload suits low-load, high-speed operations, while medium and heavy preloads are ideal for applications demanding higher stiffness and minimum backlash, such as precision CNC machinery and robotics.Q: What is the minimum achievable backlash in Shuton Precision Ball Screws, and why is it beneficial?

A: Shuton Precision Ball Screws offer backlash less than 0.005 mm, which ensures exceptional positional accuracy. This ultralow backlash is crucial for precision-driven environments like CNC machines and automation systems where repeatability is essential.Q: Which lubrication methods can be used, and how does it affect performance?

A: Both grease and oil lubrication are suitable for Shuton Ball Screws. Proper lubrication minimizes wear, enhances lifespan, and promotes smoother operation, especially under high-speed or load-intensive conditions. Choose the method based on your applications maintenance schedule and environmental factors.Q: Where can these ball screws be used, considering their construction and accuracy?

A: With their versatile mounting (flange/threaded), nut types, and robust, ground alloy steel build, Shuton Ball Screws are perfect for CNC machines, automation lines, robotic arms, and precision machine tools, particularly when high reliability and accuracy are critical.Q: What is the process for customizing stroke length, bore size, or load rating?

A: To customize stroke length (up to 6000 mm), bore size, or load ratings, consult your distributor or supplier with your applications dimensional and performance requirements. Shuton offers a wide range of modifications to ensure compatibility and optimal load capacity.Q: When should different seal types be considered for ball screw selection?

A: Labyrinth seals are best for environments with moderate contamination, while wiper seals should be used where debris, fine particles, or coolant exposure are concerns. Selecting the appropriate seal type helps extend operational life and reduces maintenance.Q: What are the main advantages of using Shuton Precision Ball Screws in high-speed applications?

A: Thanks to their precision-ground components, hardened raceways, and robust dynamic load ratings, Shuton Ball Screws support limiting speeds up to 6000 rpm. This ensures reliable performance and precise motion control in demanding, high-speed automation and machining processes.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Linear Motion Category

SBC Linear Motion Guide

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : HighGrade Alloy Steel

Seals Type : End Seals

Tychoway Linear Roller Bearings

Price 25000 INR

Minimum Order Quantity : 1 Piece

Material : Alloy Steel

Seals Type : Double Sealed

Rollico Flat Cages with Needle Roller and Balls

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Usage : Industrial

Color : silver

Zimmer Clamping and Braking

Price 7500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Bearing steel

Usage : INDUSTRIAL

Color : SILVER

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry