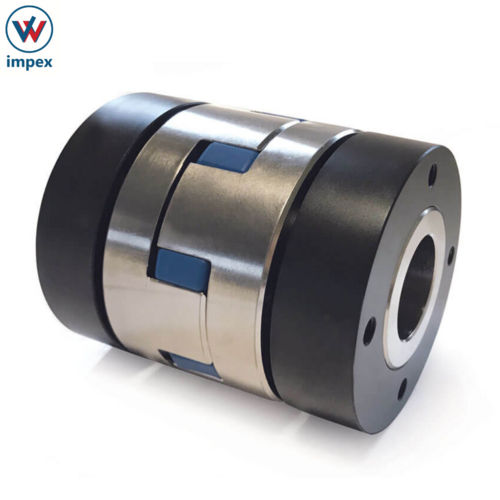

SIT Couplings & Locking Devices

Price 2500 INR/ Piece

SIT Couplings & Locking Devices Specification

- Retainer

- Self-Locking

- Precision Rating

- ISO Class 6 or better

- Inside Diameter

- Customizable as per requirement

- Thickness

- Variable as per model

- Lubrication Type

- Grease / Oil

- Material

- Alloy Steel / Stainless Steel

- Structure

- Flexible Coupling

- Seals Type

- Standard

- Number Of Rows

- Single

- Bore Size

- 20 mm to 120 mm

- Outside Diameter

- Up to 250 mm

- Limiting Speed

- Up to 5000 rpm

- Load Capacity

- High Torque Transmission

- Mounting Type

- Flange or Set Screw

- Size Availability

- Various sizes available

- Finish

- Corrosion Resistant

- Temperature Range

- -20°C to +100°C

- Misalignment Compensation

- Angular, Axial & Radial

- Compliance Standard

- DIN / ISO

- Torque Range

- Up to 25,000 Nm

- Design

- Zero Backlash

- Surface Treatment

- Phosphated or Painted

- Application

- Shaft Connection, Power Transmission

- Packaging Type

- Carton Box

About SIT Couplings & Locking Devices

SIT S.p.A. belongs to a large industrial group with historical roots that have kept the values of its founders intact over time, constantly evolving in numerous industrial sectors. Belonging to a group provides numerous synergies and financial solidity that guarantee its constant growth.

SIT is the leader in design and production of a vast and complete range of couplings that include torsionally rigid couplings, flexible couplings, zero backlash couplings, toothed couplings, couplings with shaft, bellows and disc couplings or to the client's own design.

SIT-LOCK key-way-free clamping bushings are ideal for any shaft-cube connection application. SIT-LOCK units are suitable for connecting any type of element (wheels, sprockets, gears, levers, pulleys, eccentrics, couplings, etc.) and can be used in a wide range of industrial applications.

SIT SPA is one of the leading manufactures of couplings and other power transmission products. They are world renowned for their commitment towards quality and customer satisfaction.

They offer a wide range of SIT couplings and other power transmission products such as:

TRASCO ES Couplings

SERVOPLUS Bellows Couplings

SERVOMATE Couplings

METALDRIVE Disc Couplings

SITEX ST Couplings

TRASCO Couplings

SITEX Couplings

ESAPLUS Elastic Couplings

Brass Couplings

Universal Joints

HRC Couplings

Bolt Couplings

SIT-LOCK Keyless Locking Devices

Self-Locking Bushing SERLOCK

SER-SIT Taper Bushing

SIT S.p.A. offers a vast range of self-aligning steerable monoblock bearing units and ball joints and connecting rod ends. Bearing units available in the series: cast iron, stamped sheet metal, silver, stainless silver and stainless steel.

Bearing Units and Rod Ends ASAHI

Plastic Bearing Units

ESBAL Rod Ends, Spherical Bearings and Articulations

Reliable Shaft Connection for High Torque

Experience secure and durable shaft coupling with SIT Couplings & Locking Devices, engineered for high torque transmission and flexible performance. Their robust alloy steel or stainless-steel construction ensures longevity and adaptability in challenging industrial environments, supporting torque requirements up to 25,000 Nm with no backlash.

Versatile Design Meets International Standards

SIT Couplings & Locking Devices cater to varied installation needs with customizable bore and outside diameters and a choice of corrosion-resistant surface treatments. Designed to comply with DIN and ISO standards, they deliver consistent performance across a broad temperature range and are suitable for shaft connections in power transmission applications.

Enhanced Misalignment Compensation

Benefit from reliable compensation for angular, axial, and radial misalignments thanks to the flexible coupling structure. SIT's zero-backlash design safeguards machinery from excess wear, ensuring long-term reliability and smooth operation even in dynamic or misaligned environments.

FAQ's of SIT Couplings & Locking Devices:

Q: How do SIT Couplings & Locking Devices accommodate misalignment during operation?

A: SIT Couplings & Locking Devices are designed with a flexible structure that compensates for angular, axial, and radial misalignments. This flexibility reduces vibration and mechanical stress on connected shafts, promoting smooth power transmission and prolonging equipment life.Q: What are the main applications for SIT Couplings & Locking Devices?

A: These devices are primarily used for shaft connection and power transmission in industrial machinery, where precise alignment and high torque capabilities are critical. Their design makes them ideal for various industries including manufacturing, automation, and material handling.Q: When should I choose a flange mounting type over a set screw for installation?

A: Flange mounting is recommended for applications needing stronger, more robust shaft connections and easier alignment, especially with larger diameters. Set screw mounting is suitable for smaller shafts and less demanding installations, providing a compact and straightforward setup.Q: Where are SIT Couplings & Locking Devices manufactured and exported from?

A: SIT Couplings & Locking Devices are manufactured in Italy and distributed, exported, and supplied globally through an extensive network of distributors and traders, ensuring reliable access to various industries worldwide.Q: What process is involved in customizing the bore size or outside diameter?

A: Customizations are made according to customer specifications, with precision engineering to match the required bore size (20 mm to 120 mm) or outside diameter (up to 250 mm). This ensures optimal fit and compatibility with diverse machine shafts and applications.Q: What are the benefits of SIT's zero-backlash design?

A: Zero-backlash design eliminates play between connected shafts, ensuring accurate torque transmission, reducing wear and tear, and improving the response of machinery in high-precision and dynamic applications.Q: How do I maintain SIT Couplings & Locking Devices for optimal performance?

A: Regular maintenance includes periodic inspection for wear, checking and replenishing lubrication (grease or oil as recommended), and verifying mounting integrity. Following SIT's guidelines ensures continued high performance and extends the service life of the couplings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

Kollmorgen Stepper & Servo Motors

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, HighGrade Steel Core

Structure : Robust, Precision Machined Housing

Number Of Rows : Other, Single or Multiple (Depending on Model)

Outside Diameter : 35 mm to 110 mm

Bottom Roller Bearings Textile Make Sro

Price 300-500 INR

Minimum Order Quantity : 10 Pieces

Material : Chrome steel

Structure : Deep Groove

Number Of Rows : Single Row

Outside Diameter : 32 mm

AEGIS SGR Bearing Protection Ring

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special conductive microfibers, Aluminum housing

Structure : Ring Type

Number Of Rows : Single Row

Outside Diameter : Varies as per model

CheckALL Valve

Price 8000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, 316 Stainless Steel

Structure : Check Valve

Number Of Rows : Other, Single

Outside Diameter : Varies by model

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry