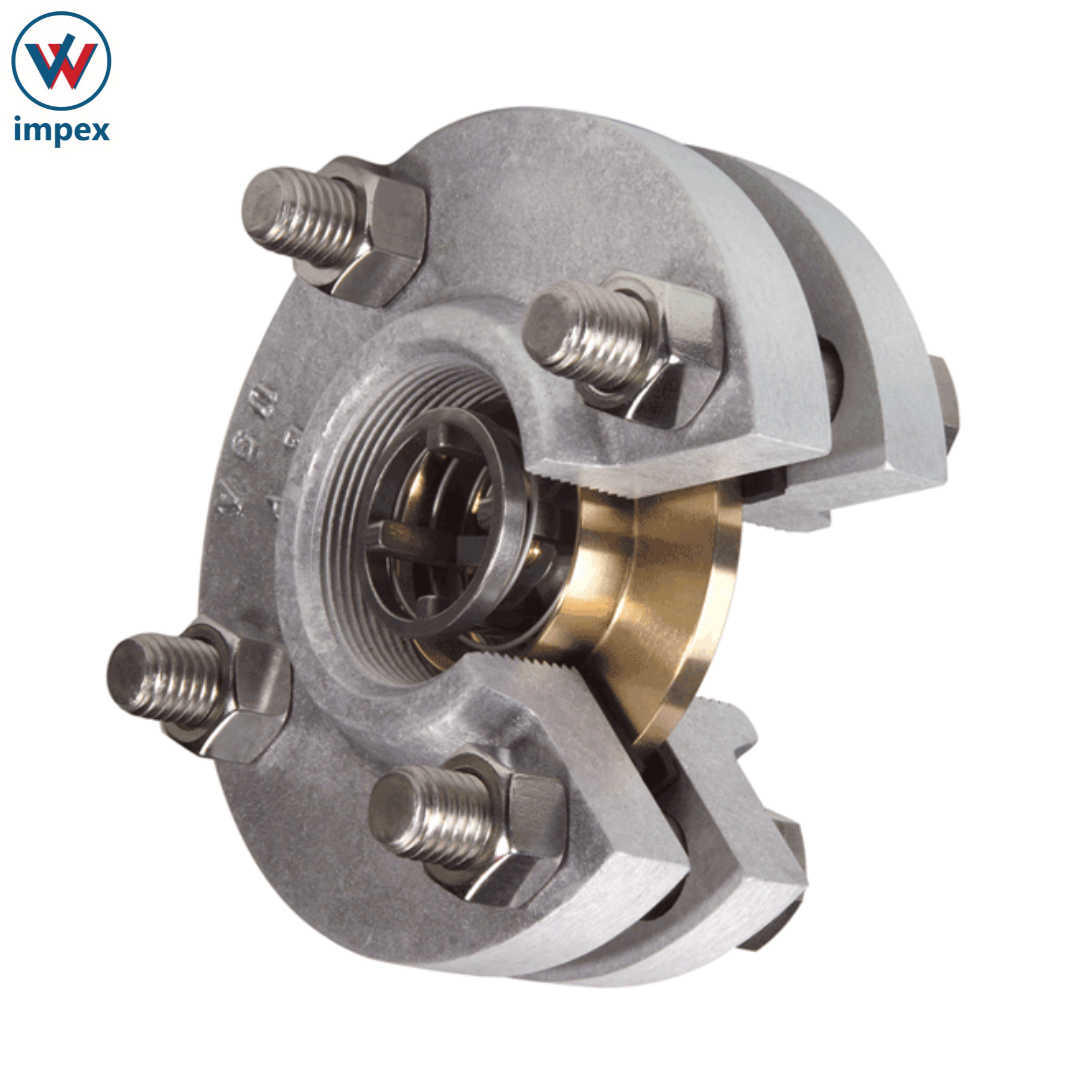

CheckALL Valve

Price 8000 INR/ Piece

CheckALL Valve Specification

- Inside Diameter

- Varies by model

- Thickness

- Varies by model

- Cage Material

- Stainless Steel

- Precision Rating

- Industrial Standard

- Retainer

- Spring

- Lubrication Type

- Self-lubricating

- Material

- 316 Stainless Steel

- Structure

- Check Valve

- Seals Type

- Viton O-ring

- Number Of Rows

- Single

- Bore Size

- 1/2 to 2 (varies by model)

- Outside Diameter

- Varies by model

- Flow Direction

- Uni-directional

- Temperature Range

- -20°C to 200°C

- End Connection

- Threaded (NPT)

- Installation Position

- Any Position

- Operating Pressure

- Up to 500 psi

- Application

- Fluid & Gas Industrial Applications

- Size Range

- 1/8" to 2" NPT

About CheckALL Valve

Since their inception in 1958, Check-All Valve has expanded from producing one valve with one material to manufacturing a series of valves in a wide range of materials. Many companies manufacture check valves in addition to other product lines; however, they are dedicated solely to the design and manufacture of check valves.

Check-All Valve produces a complete line of inline, spring-loaded, poppet-style check valves to serve a wide range of industries and practically every service application. Every Check-All valve is designed and built to perform to your exact needs and specifications. Their spring check valves are offered with metal-to-metal or soft seats in sizes ranging from 1/8 NPT to 20 flanged connections. Spring cracking pressures range from 1/8 PSI to 85 PSI and virtually any setting in between. Pressure ratings are available from full vacuum to 10,000 PSI with standard and exotic materials of construction also available.

Types of Check-All Valve:

1) Silent Check Valves - A silent check valve utilizes a spring to assist the poppet in closing the check valve prior to fluid flow reversal. This eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden stoppage of flow in a fluid process system.

2) Spring Loaded Check Valves - A spring loaded check valve (a.k.a. spring check valve) incorporates a spring to assist in closing the check valve. They are designed to close prior to fluid flow reversal. Preventing backflow eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden fluid stoppage of flow in a fluid process system.

3) Poppet Check Valves - A poppet check valve incorporates a disc (normally at the end of a "sleeve or "stem) utilized as the checking mechanism. It is often spring loaded to help close the valve prior to fluid flow reversal. This eliminates the hydraulic shock also known as water hammer. Water hammer is a result of the sudden fluid stoppage of flow in a fluid process system.

4) Inline Check Valves - Inline check valves utilize a check mechanism that functions in the fluid line or media pathway of a process piping system. Oftentimes, these check valves are of a compact design allowing for space saving and/or ease of installation into an existing system.

Styles of CheckValve :

1) Flange Connection

Flange Insert Check Valve Style F1, F6, FP

Horizontal, Vertical, Flanged & Drilled Style Check Valve HV

Wafer Insert Check Valve Style WV

2) Threaded Connection

Adapter Check Valve Style AM, AF

Bushing Check Valve Style BU, BR

Connector Check Valve Style CN, CR

Mini-Check Valve Style M1, M8

Universal High-Pressure Check Valve Style U1, R1

Universal Low-Pressure Check Valve Style U3, UR

3)Sanitary Connection

3-A Sanitary Check Valve Style 3S

Sanitary Cartridge Check Valve Style SC

Sanitary Insert Check Valve Style CB, TC

4) Welded Connection

Butt Weld Check Valve Style B4, B8

Universal Socket Weld Check Valve Style US

5) Tubing Connection

Tubing Check Valve Style TV

Tubing Check Valve, Flared Style TF

6) Lined Pipe Connection

Horizontal, Vertical, Flanged & Drilled PTFE Lined Style HT

Lined Pipe Insert Check Valve Style LP

Robust Fluid and Gas Handling

Manufactured from high-quality 316 stainless steel with a Viton O-ring, the CheckALL Valve offers excellent corrosion resistance and sealing performance. It efficiently manages both fluid and gas flows in demanding industrial environments, supporting pressures up to 500 psi and temperatures from -20C to 200C. This makes it suitable for a variety of industrial applications that require reliability and safety.

Flexible and Easy Installation

With threaded NPT end connections and compatibility with any installation position, the CheckALL Valve adapts effortlessly to new or existing piping systems. Its single-row structure and simple mounting process facilitate quick integration, minimizing downtime during maintenance or upgrades. Available in multiple sizes, it ensures a perfect fit for your specific requirement.

Designed for Industrial Standards

Precision-rated for industrial use, this valve incorporates a stainless steel spring retainer and self-lubricating components to ensure longevity and dependable operation. Its sturdy design, coupled with export, import, and supply capabilities in the United States, make it a trusted choice for distributors and traders in the sector.

FAQ's of CheckALL Valve:

Q: How does the CheckALL Valve ensure leak-proof operation in industrial applications?

A: The CheckALL Valve uses a robust 316 stainless steel body paired with a Viton O-ring seal, which together provide exceptional resistance against pressure and temperature fluctuations. This ensures a reliable, leak-proof seal in both fluid and gas handling systems.Q: What is the recommended process for installing the CheckALL Valve?

A: Simply thread the valve into the NPT pipe connection of your system, ensuring flow direction matches the uni-directional marking. It can be installed in any position-vertical or horizontal-making installation straightforward with minimal requirements.Q: When should I consider using the CheckALL Valve in my application?

A: This check valve is ideal when you need to prevent backflow in fluid or gas applications operating up to 500 psi and within a temperature range of -20C to 200C. It fits well in a variety of industrial, commercial, or utility piping systems.Q: Where can this valve be utilized?

A: The CheckALL Valve is suitable for many industries, such as chemical processing, water treatment, gas distribution, and manufacturing facilities-any environment where controlled, one-way fluid or gas flow is necessary.Q: What are the benefits of the self-lubricating feature?

A: The self-lubricating design minimizes maintenance needs by reducing friction and wear on internal components. This enhances operational reliability and extends the service life of the valve, even in demanding environments.Q: How can I select the proper size of CheckALL Valve for my system?

A: Choose a size that matches your pipe threading (1/8" to 2" NPT) and consider the required bore size (1/2" to 2") based on your application's flow rate. Consult technical data sheets or speak to a supplier for help in selecting the right model for optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

Saurer Temco Bearing

Price 3600 INR / Piece

Minimum Order Quantity : 2 Pieces

Size : Different Available

Usage : Industrial

Warranty : Yes

Color : silver

IGUS Bearing

Price 790 INR / Piece

Minimum Order Quantity : 5 Pieces

Size : Different Available

Usage : Industrial And Commercial

Warranty : Yes

Color : White And Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry