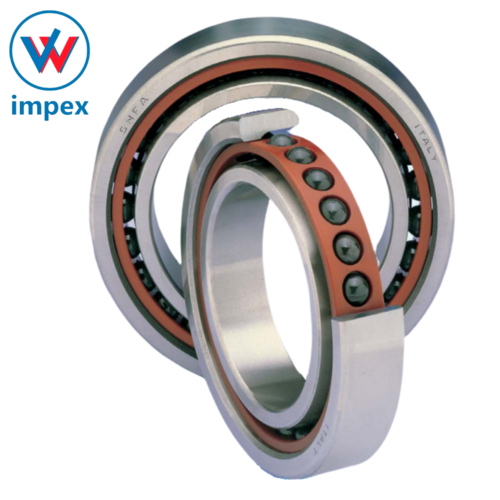

RHP Super Precision Bearing

Price 7500 INR/ Piece

RHP Super Precision Bearing Specification

- Inside Diameter

- 15 mm

- Lubrication Type

- Grease

- Cage Material

- Brass

- Thickness

- 11 mm

- Precision Rating

- P5

- Retainer

- Brass

- Usage

- Industrial

- Bearing Type

- Super Precision

- Material

- Steel

- Size

- Different Available

- Structure

- Angular Contact Ball Bearing

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 15 mm

- Color

- silver

- Outside Diameter

- 35 mm

- Limiting Speed

- 40000 RPM

- Load Capacity

- High

- Application

- Machine Tools, Spindle Motors

- Finish

- Polished

- Static Load Rating

- 5200 N

- Temperature Range

- -30°C to +120°C

- Vibration Level

- Low

- Dynamic Load Rating

- 8000 N

RHP Super Precision Bearing Trade Information

- Minimum Order Quantity

- 1 Piece

- Delivery Time

- 7 Days

About RHP Super Precision Bearing

RHP Bearings have a long heritage, which is respected throughout the world. RHP Super Precision Bearing (Ransom, Hoffman and Pollard) was formed in 1969 as a result of the amalgamation of three of the UK's leading bearing manufacturers. RHP Bearings has gone onto field of various bearing types in a multitude of applications. NSK a major world force in rolling bearing technology is an organization committed to global localization. Recognizing the synergy with RHP since 1990, NSK joined force to create NSK-RHP which is strongly identified as a core brand by customers throughout the world.

Currently NSK-RHP has three specialties:

- RHP Inch series bearing

- RHP Bearing units incorporated into different housings

- RHP Super Precision Bearings for Machine Tool Application

In the field of modern machine tool building, instrument making and other engineering activities, ever increasing demands are placed on bearing performances in the terms of higher rotational accuracies and speeds. These demands are reliably met with RHP Super Precision Bearings, which demonstrates the following distinct features:

Features:

- Extreme accuracy

- High rotational speed

- Minimum friction and heat generation

- Controlled rigidity

NSK-RHP Super Precision Bearings:

NSK-RHP manufacturers three basic types of Super Precision Bearings:

- Single row angular contact ball bearings

- Ball screw support bearings

- Single row radial ball bearings

- Angular contact ball bearings

This is the most adaptable and important bearing within the NSK-RHP range for use in machine tool spindles. The many combinations of contact angle and preload allow precise bearing selection to cope with most arduous of requirements, be they speed or capacity. The range has preferred contact angles 15 degrees and 25 degrees and laminated phenolic resin cages. Bearings can be supplied singly, in paired units or multiple sets.

The NSK-RHP Excel range has been introduced in response to industries need for higher speeds and has a larger number of balls. They also offer higher stiffness. They are dimensionally interchangeable with bearings with normal ball diameter. The NSK-RHP Ultra range is designed for particularly high speed application.

The NSK-RHP Excel, Ultra and normal ranges can be supplied with silicon nitride (ceramic) balls. These offer higher speeds and lower operation temperatures, as well as enhanced stiffness.

Ball Screw Support Bearings:

- NSK-RHP has available a comprehensive range of ball screw support bearings, cartridge and pillow block

- Units Ball Screw support bearings with their high rigidity, low torque, simple mounting and elimination

- Of the need for preload adjustment provide ideal support solution

- RHP ball screw support bearings are

Designated BSB have 60 degrees contact angle and are manufactured to P3 tolerances. The balls are separated by one piece, glass fiber reinforced nylon molded cage.

High Precision Engineering

Designed with a P5 precision rating, this bearing delivers exceptional accuracy and smooth motion for applications that demand superior performance. Its high load capacity and low vibration levels make it ideal for machine tools where reliability and consistency are critical.

Reliable Operation Across Temperatures

The bearing operates efficiently within a temperature range of -30C to +120C, allowing it to perform reliably in various industrial settings. Its robust construction and premium materials provide dependable performance, even under challenging thermal conditions.

Versatile Industrial Application

With different sizes available and a high-speed capability of up to 40,000 RPM, the RHP Super Precision Bearing is suitable for diverse industrial sectors. Its angular contact design and open seal type facilitate easy maintenance and effective lubrication when used with quality grease.

FAQs of RHP Super Precision Bearing:

Q: How is the RHP Super Precision Bearing typically used in industrial applications?

A: The bearing is commonly employed in machine tools and spindle motors, where accuracy, high speed, and load capacity are crucial for productivity and longevity. Its precision and low vibration make it suitable for sensitive industrial processes.Q: What is the process for installing this angular contact ball bearing?

A: Installation should be carried out in a clean environment, ensuring the bearing and housing are free of contaminants. Proper alignment is essential, and lubrication with high-quality grease must be applied before use to guarantee optimal performance and lifespan.Q: When should this bearing be selected over other types?

A: This super precision bearing is ideal when your machinery demands high speed, excellent load handling, and minimal vibration, especially in machine tools and spindle applications. Its precision rating and robust structure provide superior results in these use cases.Q: Where can I source RHP Super Precision Bearings in India?

A: RHP Super Precision Bearings are available through authorized distributors, exporters, importers, suppliers, and traders throughout India. It is recommended to purchase from reputable dealers to guarantee authenticity and proper support.Q: What benefits does the P5 precision rating provide to industrial users?

A: The P5 precision rating ensures high dimensional accuracy and consistent performance, reducing operational noise, vibration, and wear. This translates to longer machine life, improved productivity, and lower maintenance costs for industrial users.Q: How does the open seal structure affect the bearings operation and maintenance?

A: The open seal design enables easier monitoring and access for lubrication, making maintenance straightforward. However, it is essential to protect the bearing from exposure to contaminants in the environment for optimal operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precision Bearings Category

IBC Super Precision Bearing

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Bearing Type : Ball Bearing

Load Capacity : High

Structure : Angular Contact

NSK Super Precision Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Bearing Type : Other, Super Precision

Load Capacity : High

Structure : Angular Contact

NTN Super Precision Bearings

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, Bearing Steel

Bearing Type : Other, Super Precision

Load Capacity : High

Structure : Angular Contact

SNFA Precision Bearing

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry