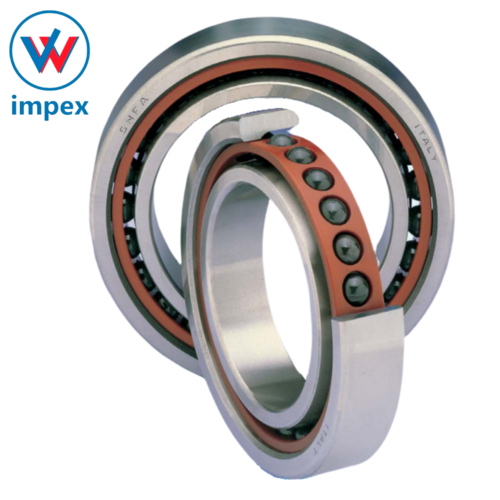

NTN Super Precision Bearings

Price 10000 INR/ Piece

NTN Super Precision Bearings Specification

- Retainer

- Brass

- Thickness

- 16 mm

- Inside Diameter

- 30 mm

- Precision Rating

- P4

- Cage Material

- Brass

- Lubrication Type

- Grease

- Bearing Type

- Super Precision

- Material

- Bearing Steel

- Structure

- Angular Contact

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 30 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 17000 RPM

- Load Capacity

- High

- Static Load Rating

- 13.8 kN

- Standard

- ISO 492

- Vibration Level

- V1

- Contact Angle

- 15°

- Application

- Machine Tool Spindles

- Heat Resistance

- Up to 120°C

- Dynamic Load Rating

- 19.5 kN

About NTN Super Precision Bearings

NTN offers a wide range of Precision Angular Contact Ball Bearings for use in high speed machining. These product designs are manufactured to address both radial & thrust loads while still maintaining speed requirements needed for metalworking and other machining processes. These designs are normally found in CNC spindles which are critical for maintaining tight tolerances to achieve proper finished goods in manufacturing.Precision Cylindrical Roller Bearings are essential in spindle designs utilized in the manufacturing marketplace. Both single and double row precision cylindrical roller bearing designs are manufactured with tighter tolerances and clearance options to maintain efficient finished goods. Cylindrical rollers bearings are required where thrust loads and rigidity are present in the machining process.

Precision Taper Roller Bearings are utilized within some CNC machining processes. They are found in small spindle designs that require heavy thrust load capabilities. They also can be found in other machining functions not related to the primary spindle itself. Their precision taper rollers are manufactured with tighter tolerances to maintain proper functionality.

The rigidity of the main spindle of a machine tool is associated with both bearing rigidity and shaft rigidity. Bearing rigidity is typically governed by the elastic deformation between the rolling elements and raceway surface under load. Usually, bearings are preloaded in order to increase the rigidity. Under same loading conditions, a roller bearing has a higher rigidity than a ball bearing of the same size.

NTN High Precision Bearings combine leading technology and the expertise of a global leader to optimize the performance of your machine. The range of precision bearings has been developed by NTN experts in close collaboration with some of the biggest names in machine tools. The benefit of the range:

Productivity: optimized production cost

Accuracy: high-quality machining

Reliability: reduced maintenance costs

Eco-Design: environmental protection

The range features the ULTAGE label, proof of its ultimate performance.

Spindle Bearings

High Precision Angular contact ball bearings - Standard, High-Speed and Ultra-high-speed

High precision cylindrical roller bearings with 1 or 2 rows of rollers - Standard and High-Speed

Angular Contact Ball Bearings for Axial loads

Ball Screw Support Bearings

BSTU - sealed

BST - open/sealed

Exceptional Precision for Demanding Spindles

NTN Super Precision Bearings are optimized for machine tool spindle applications, ensuring remarkable rotational accuracy and stability at high speeds. Manufactured to P4 precision standards, they provide consistent performance in environments requiring tight tolerances and minimal vibration.

High-Quality Construction for Longevity

Crafted from premium bearing steel and equipped with a brass cage and retainer, these bearings deliver durability and reliability. The open-seal design allows effective grease lubrication, supporting a long service life and reduced maintenance intervals.

Robust Performance in Challenging Conditions

With a dynamic load rating of 19.5 kN and static load rating of 13.8 kN, this bearing ensures high load-bearing capability. Its heat resistance up to 120C and limiting speed of 17,000 RPM make it suitable for continuous, high-speed operation.

FAQ's of NTN Super Precision Bearings:

Q: How do NTN Super Precision Bearings enhance machine tool spindle performance?

A: These bearings are engineered for high speed, accuracy, and load capacity, directly enhancing the precision and stability of machine tool spindles. Their P4 precision rating and 15 contact angle deliver smooth operation and reliable performance, even during complex machining tasks.Q: What makes this bearing suitable for high-speed spindle applications?

A: With a limiting speed of 17,000 RPM, a robust brass cage, and superior heat resistance up to 120C, this bearing is ideal for high-speed operations. The angular contact structure helps distribute loads efficiently, ensuring longevity and top performance.Q: When should I choose an NTN Super Precision Bearing with an open seal type?

A: Open seal types are best suited for environments where regular relubrication is possible and where lower friction is required. It allows for efficient heat dissipation and is perfect for applications like CNC machine tool spindles in controlled settings.Q: Where can I purchase NTN Super Precision Bearings in Japan?

A: These bearings are available through authorized distributors, exporters, importers, suppliers, and traders across Japan. Always verify the authenticity and specifications with the supplier to ensure the best fit for your application.Q: What is the recommended lubrication process for this bearing model?

A: Grease lubrication is recommended for this open-type bearing. Ensure that high-quality grease is used, and regularly relubricate following equipment manufacturer's guidelines to maintain optimal performance and lifespan.Q: How does the single-row design benefit my application?

A: The single-row angular contact design supports both radial and axial loads in a single direction, ideal for precise spindle arrangements. This structure minimizes internal friction and helps maximize speed and accuracy.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precision Bearings Category

RHP Super Precision Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Steel

Color : silver

Precision Rating : P5

Lubrication Type : Grease

NSK Super Precision Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Precision Rating : P4

Lubrication Type : Other, Grease/Oil

IBC Super Precision Bearing

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Precision Rating : P4

Lubrication Type : Grease

SNFA Precision Bearing

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry