IBC Super Precision Bearing

Price 5000 INR/ Piece

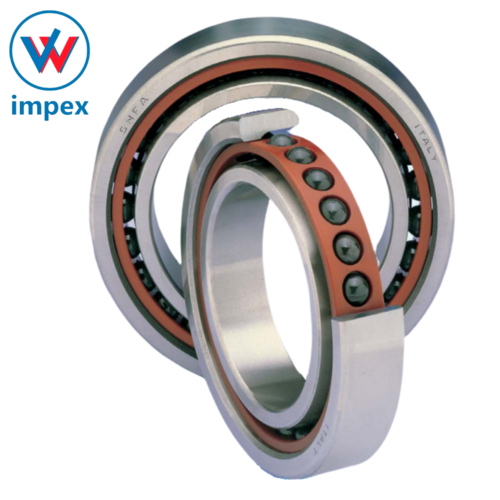

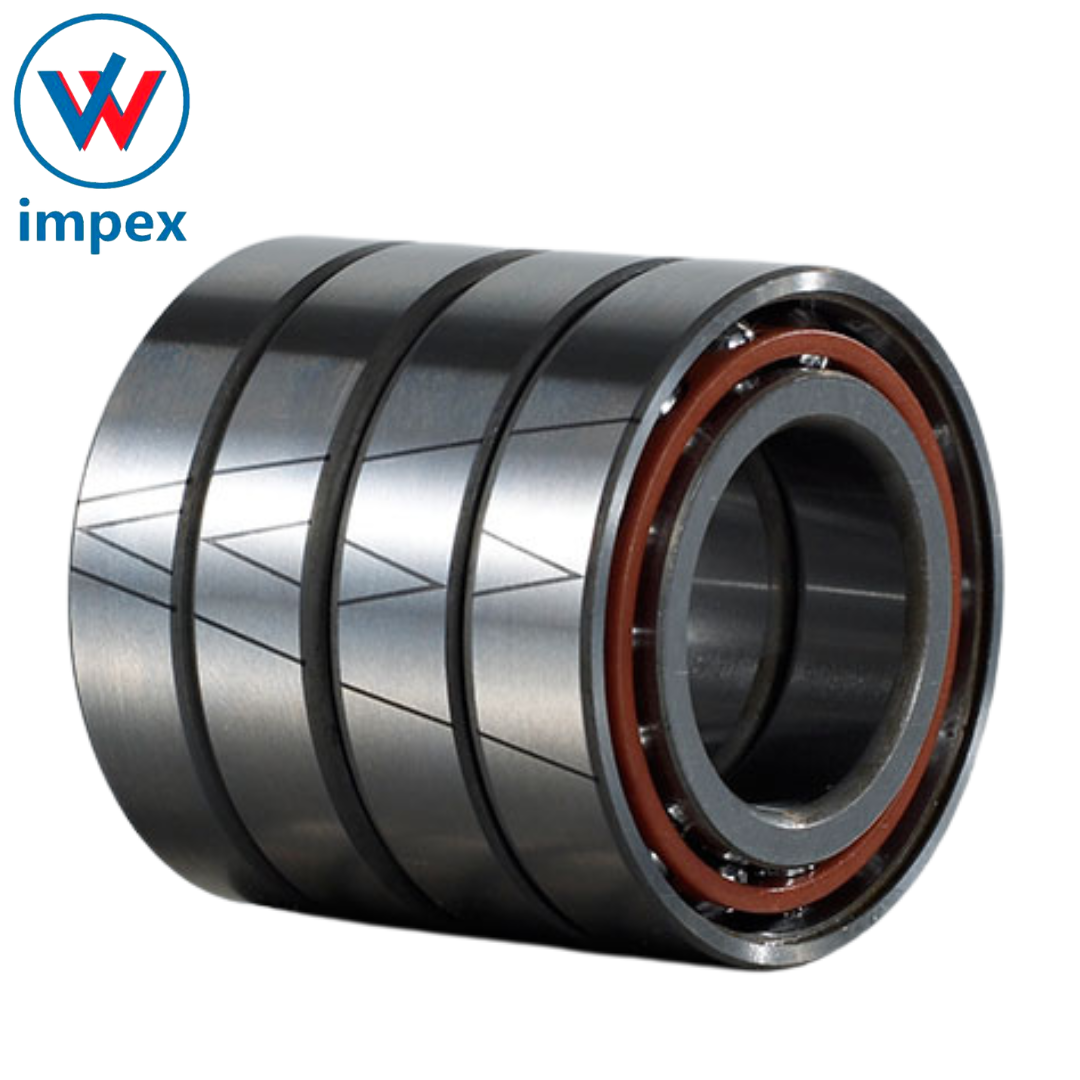

IBC Super Precision Bearing Specification

- Precision Rating

- P4

- Thickness

- 16 mm

- Lubrication Type

- Grease

- Retainer

- Steel

- Cage Material

- Sheet Steel

- Inside Diameter

- 30 mm

- Bearing Type

- Ball Bearing

- Material

- Chrome steel

- Structure

- Angular Contact

- Seals Type

- Open

- Number Of Rows

- Single Row

- Bore Size

- 30 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 18000 rpm

- Load Capacity

- High

- Noise Level

- Low

- Finish

- Polished

- Manufacturing Brand

- IBC

- Vibration Level

- Minimal

- Contact Angle

- 15°

- Temperature Range

- -30°C to +120°C

- Application

- Machine Tool Spindles

- Static Load Rating (C0)

- 17.6 kN

- Dynamic Load Rating (C)

- 29.6 kN

About IBC Super Precision Bearing

IBC Super Precision Bearing

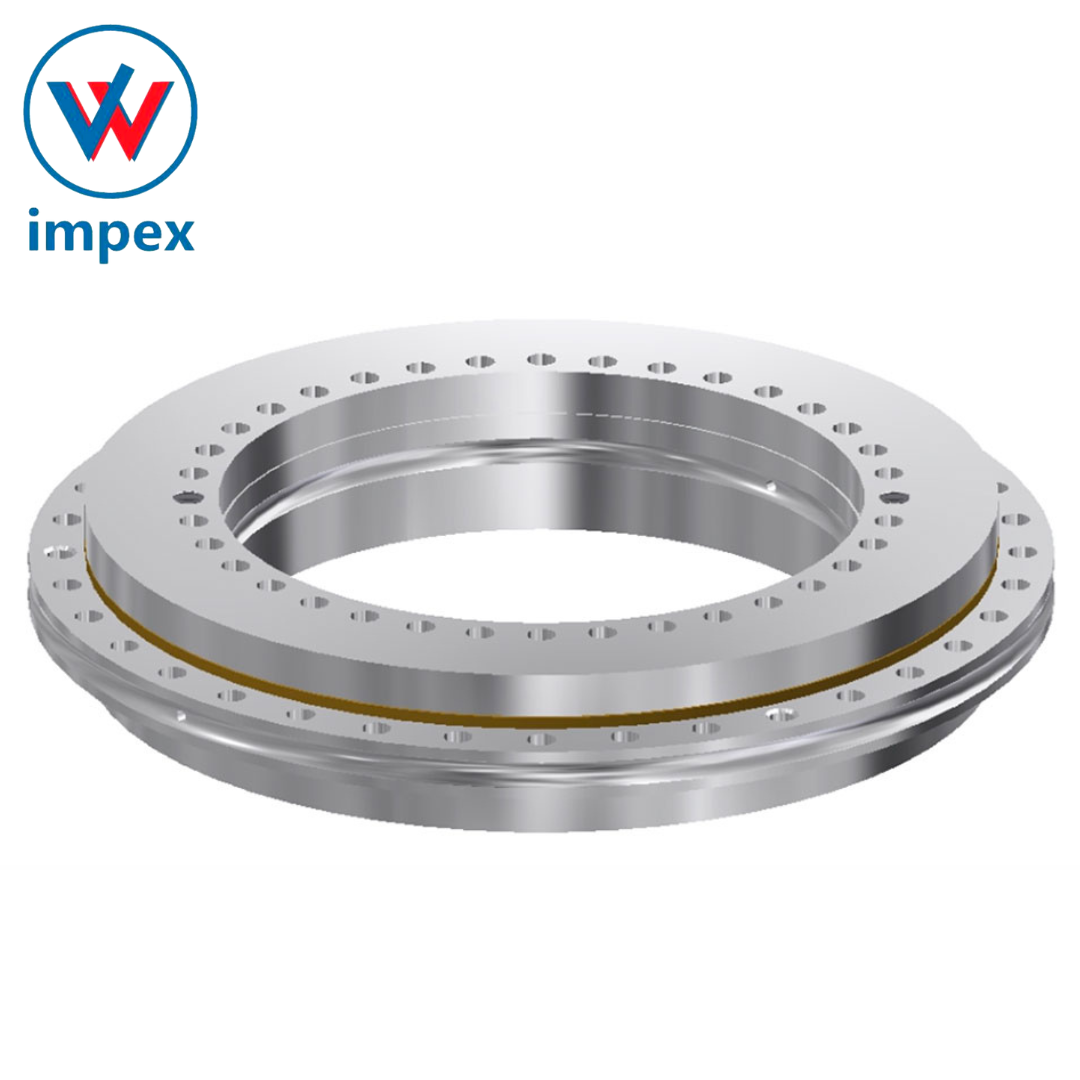

BC offers an exceptionally high quality range of precision and super precision bearings from their production plants in Germany and Switzerland.

Their capability to innovate has set them apart from other manufactures. The use of different materials for bearing components has been one of the divisive factors in increasing the performance of their products. The use of ceramic rolling elements, enhanced cage materials like PEEK overcome challenging environments.

IBCs product range is further enhanced by AT Coat thin dense chrome plated bearings which are designed for special applications, offering service life boosting characteristics as well as outstanding wear and corrosion protection properties.

The innovative way that IBC holds stock in component form and their streamlined assembly program allows for greatly reduced delivery lead times on matched bearings and special assemblies incorporating non standard materials produced specifically for customers actual requirements.

Product solutions include:

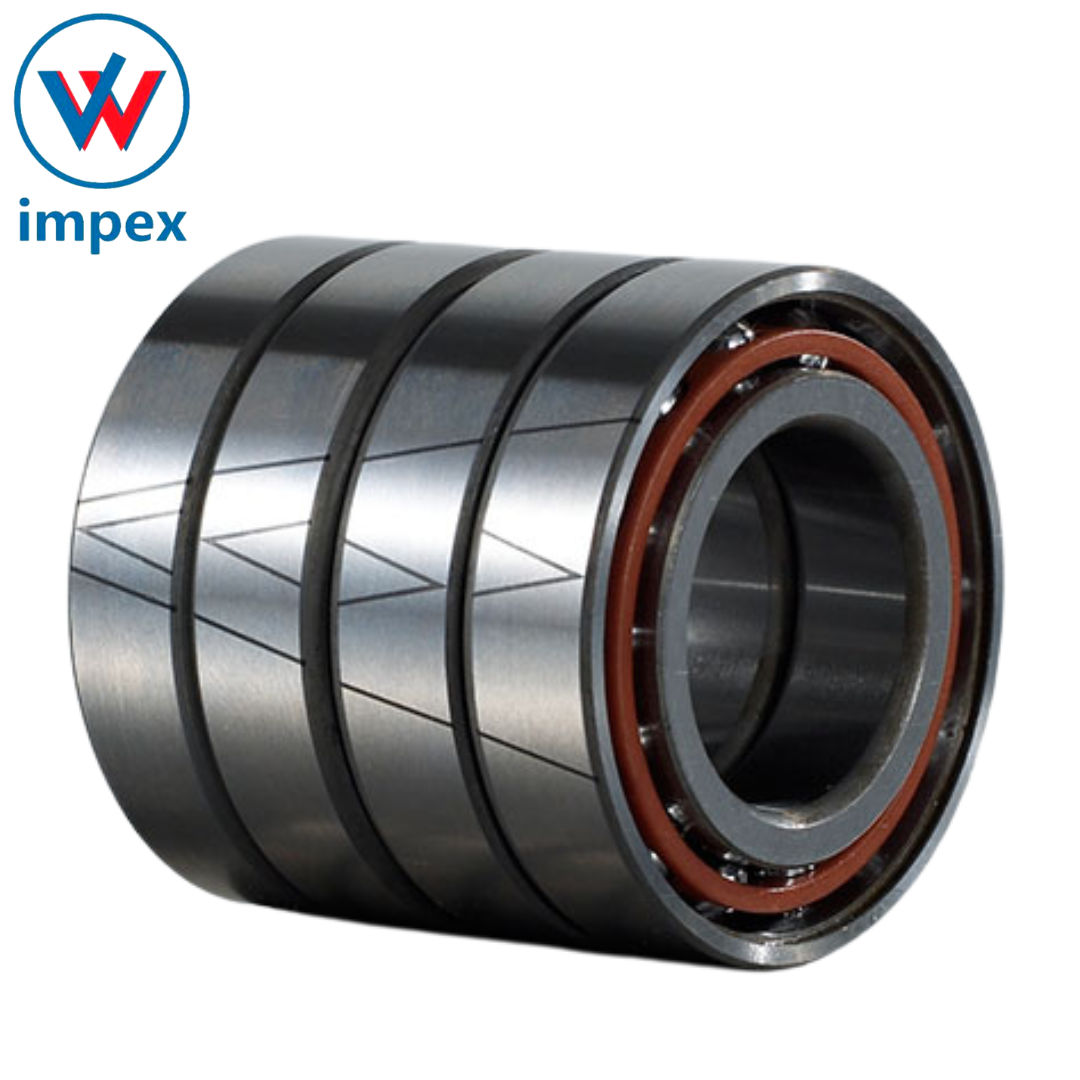

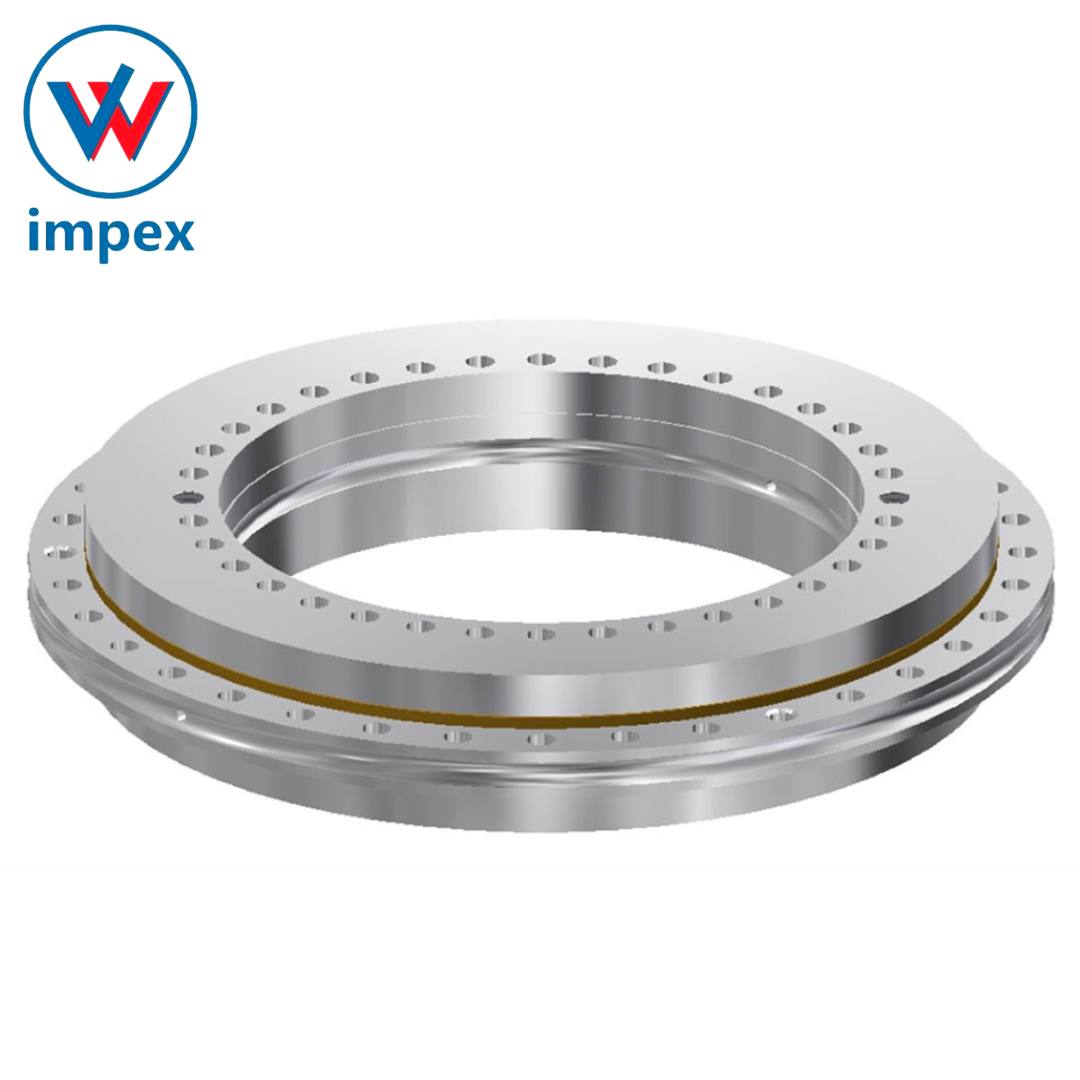

- Super Precision Angular Contact Ball Bearings

- Cylindrical Roller Bearings

- Ball Screw Support Bearings

- ATCoat Rolling Bearings

- Precision Locknuts

- Linear Motion Bearings

Superior Performance for Machine Tool Spindles

Designed specifically for machine tool spindles, the IBC Super Precision Bearing guarantees precise rotation and robust load handling. Its advanced angular contact structure, paired with P4 precision and high-quality chrome steel, minimizes operational errors even under high-speed conditions, ensuring top-tier machining outcomes.

Optimal Operating Conditions and Durability

This bearing operates seamlessly across a wide temperature range (-30C to +120C), maintaining integrity in demanding environments. Featuring a polished finish and sturdy steel retainer, the bearing resists wear and tear, offering a long service life and reliable performance in industrial settings.

Precision Engineering and Versatile Applications

IBCs bearings are meticulously crafted to meet rigorous precision requirements. With its single row angular contact configuration, 30 mm bore size, and 62 mm outer diameter, this bearing suits a range of high-speed spindle applications, making it an excellent choice for exporters, importers, and suppliers across India.

FAQs of IBC Super Precision Bearing:

Q: How should the IBC Super Precision Bearing with a 15 contact angle be installed for optimal performance?

A: To achieve optimal performance, the bearing should be installed carefully with precise alignment and correct axial load. Ensure the spindle and bearing seats are clean and accurately machined to maintain the tight tolerances required for P4 precision.Q: What are the main benefits of using this bearing in machine tool spindle applications?

A: This bearing offers high dynamic and static load capacities, minimal noise and vibration, high rotational accuracy, and outstanding durability, resulting in improved machine efficiency and extended service intervals.Q: When is it necessary to re-lubricate the IBC Super Precision Bearing?

A: The re-lubrication interval depends on speed, load, and operating conditions, but periodic checks are recommended. As this bearing uses grease lubrication and is of the open type, re-lubrication may be needed more frequently under continuous or high-speed operation.Q: Where can this bearing be used outside of machine tool spindles?

A: Although optimized for machine tool spindles, this bearing is suitable for any high-precision, high-speed industrial application where minimal vibration and exceptional load capacity are required, such as robotics or automated machinery.Q: What is the process for sourcing IBC Super Precision Bearings in India?

A: IBS Super Precision Bearings can be sourced through authorized distributors, importers, suppliers, and traders across India who specialize in industrial bearings and provide technical support for selecting and installing the right bearing type.Q: How does the P4 precision rating benefit machine tool operations?

A: The P4 precision rating ensures tight tolerances, reduced rotational errors, and highly consistent performance, all of which are critical for high-accuracy machining and prolonged bearing life.Q: What lubrication type is recommended for this bearing and why?

A: Grease lubrication is recommended due to the bearings open type design. Grease ensures adequate coverage and protection for high-speed applications, reducing maintenance requirements and effectively dissipating heat.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precision Bearings Category

RHP Super Precision Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Steel

Precision Rating : P5

Color : silver

Thickness : 11 mm

NSK Super Precision Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Precision Rating : P4

Thickness : 18 mm

NTN Super Precision Bearings

Price 10000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, Bearing Steel

Precision Rating : P4

Thickness : 16 mm

SNFA Precision Bearing

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : Silver

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry