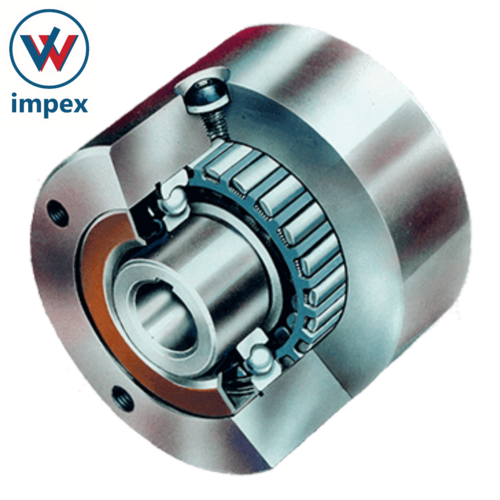

GMN Freewheel Clutch

Price 18900 INR/ Piece

GMN Freewheel Clutch Specification

- Lubrication Type

- Grease Lubrication

- Thickness

- 17 mm

- Retainer

- Steel

- Precision Rating

- P0, P6 (Standard/High-Precision)

- Cage Material

- Steel

- Inside Diameter

- 25 mm

- Bearing Type

- Freewheel Clutch

- Material

- Chrome steel

- Structure

- Single Row Cylindrical Roller Freewheel

- Seals Type

- Sealed

- Number Of Rows

- Single

- Bore Size

- 25 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 4500 rpm

- Load Capacity

- 900 Nm

About GMN Freewheel Clutch

The insert elements consist of a cage, sprags - number in relation to the shaft size - and a spring to preload the friction contact between the sprags and the mating parts. So called insert elements are not self centering and require additional bearing support for proper function as provided with our complete units, ball bearing sizes and backstops.

FUNCTION : The functional principle of sprag type freewheel clutches is based on static friction. A certain number of sprags are in constant friction contact with the connecting parts. Sprags are components with variable height. They are uprighted when the connecting parts are rotated and clamped between the connecting parts while there is static friction between sprags and connecting parts. The static friction is guaranteed by a specific geometry (clamping angle) of the sprags to the connecting parts.

GMN sprag type freewheel clutches are extremely space-saving and offer outstanding torque, indexing reliability/frequency and service life.

Versatile Applications in Motion Control

Perfect for applications that demand controlled motion locking and unidirectional rotation, the GMN FC 25 freewheel clutch is indispensable in systems requiring backstop, overrunning, or indexing functions. Its robust construction and reliable performance make it suitable for use in industrial automation, conveyors, machinery, and motor drives.

Precision Engineering and High Durability

Crafted from premium chrome steel with a precision ground finish, the FC 25 ensures excellent durability and superior rotational performance. The clutch features a sealed design to protect from contaminants, whilst grease lubrication extends operational lifespan even in demanding environments. The model meets both standard and high-precision requirements (P0, P6).

FAQ's of GMN Freewheel Clutch:

Q: How is the GMN FC 25 Freewheel Clutch typically mounted in machinery?

A: The FC 25 can be mounted using either a press fit or with a keyway, offering flexibility to match various shaft mounting preferences in industrial setups.Q: What are the main applications for the GMN FC 25 Freewheel Clutch?

A: This model is commonly used as a backstop, indexing clutch, or overrunning clutch in conveyors, drive systems, and other machinery requiring controlled, one-way motion.Q: When should I choose FC 25 with a keyway inner ring versus a plain type?

A: Opt for the keyway type when positive torque transmission with a shaft key is needed. The plain type suits applications that require a press fit for smooth, continuous operation.Q: Where can I source the GMN FC 25 Freewheel Clutch?

A: As a distributor, exporter, importer, supplier, and trader of German precision products, you can acquire the FC 25 from authorized sellers specializing in GMN components.Q: What is the process for selecting the correct direction of rotation?

A: Select right or left one-way rotation depending on your system's functional requirements; the clutch is factory-configured to engage in the specified direction.Q: How does the FC 25 benefit machinery performance?

A: Its high load capacity, precision rating, and sealed, grease-lubricated design ensure reliable unidirectional motion, minimize maintenance, and extend operational life, thereby boosting overall machinery efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

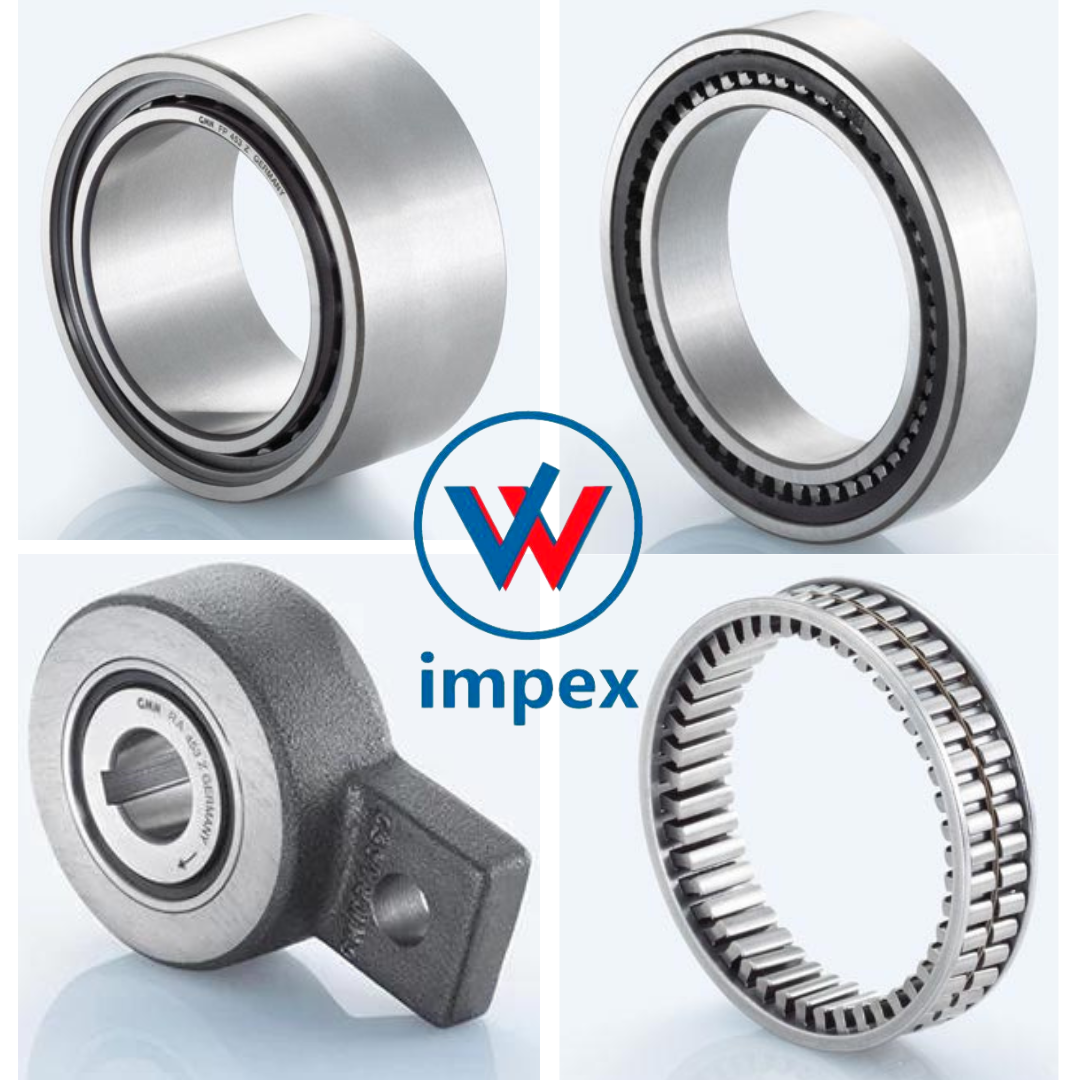

More Products in Clutches & Brakes Category

Free Wheel Clutches Bearing

Price 2000

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Thickness : 17 mm

Retainer : Steel

Structure : Single Row Roller Clutch

Cross and Morse Freewheel Clutch

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Thickness : 19 mm

Retainer : Steel

Structure : Sprag Type Freewheel Clutch

Ringspann Freewheel Clutch

Price 19000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Thickness : 20 mm

Retainer : Metal Retainer

Structure : Single Row Freewheel Clutch

Stieber Freewheels Clutch

Price 2500

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Thickness : 17 mm

Retainer : Steel

Structure : Clutch Freewheel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry