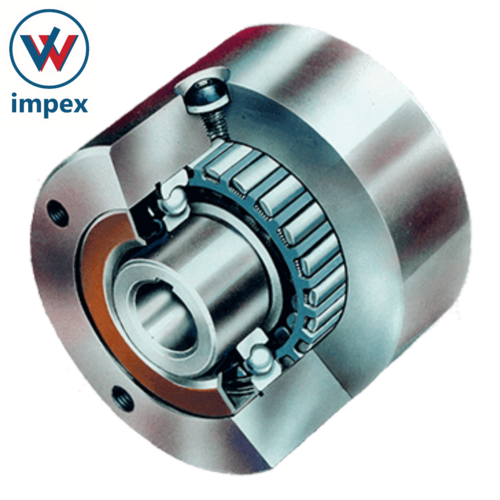

Cross and Morse Freewheel Clutch

Price 50000 INR/ Piece

Cross and Morse Freewheel Clutch Specification

- Thickness

- 19 mm

- Retainer

- Steel

- Cage Material

- Steel

- Lubrication Type

- Grease Lubrication

- Inside Diameter

- 35 mm

- Precision Rating

- P6

- Bearing Type

- Freewheel Clutch

- Material

- Alloy Steel

- Structure

- Sprag Type Freewheel Clutch

- Seals Type

- Metal Shielded

- Number Of Rows

- Single Row

- Bore Size

- 35 mm

- Outside Diameter

- 72 mm

- Limiting Speed

- 2500 RPM

- Load Capacity

- 3200 Nm

About Cross and Morse Freewheel Clutch

Cross & Morse Freewheels provide positive one-way drive with high torque capacity within a small unit. A ratchet and pawl mechanism is used with materials and heat treatment selected for a long operating life, with safe, positive transmission. IRFs are suited to low speed (up to 150 r.p.m.) overrun applications where shock loads may be encountered, such as Agricultural machinery. Standard stock units are available in two configurations; as standard sprocket for 1/2 inch pitch chains, or with a drilled flange to fit conveyor rollers, pulleys, or wheels. Standard units have threaded bore to cycle standards, but a range of Adapters enable fitting to keyed shafting. IRF clutches are also stocked in part-assembled condition for reworking to custom design, including finish parallel bore and key seat. Many special Industrial Ratchet Freewheels have been manufactured to meet customers requirements with torques over 1,000.Cross Safegard Overload Clutches

The Safegard series of overload clutches were developed to provide overload protection of high torque values with a compact unit. Directly interchangeable with other units in the market, this series offers low cost precision with minimal maintenance for a long reliable service life.

Safegard clutches are in two basic series, the Standard series, for optimum speed and torque, and the Mini series, for lower cost option on slower speed drives. Both series are also available as shaft couplings.

Torque Limiters & Couplings

The Morse Torque Limiter is a protective device that LIMITS TORQUE transmitted in a drive system by slipping when the torque demand exceed a preset value as a result of shock loads, overloads, or machine jams. It automatically re-engages when the overload torque has passed; no re-setting is required. It prevents machine damage and eliminates costly breakdown time.

The Torque Limiter utilises spring loaded friction surfaces for its operation; slip torque is preset by adjustment of the spring force. The Torque Limiter can be used with a sprocket, gear, sheave or flange as the center member clamped between two friction facings. Offered complete with a range of specially machined plate wheels and shaft to shaft couplings, with torque range 3 - 8540 Nm.

Tensioners

Spring loaded tensioners extend the life of roller chain, particularly on long centre distance drives. These products are suitable for simplex and multi strand applications.

Rotary Tensioner: Automatic 90* tensioning action.

Linear Tensioner: Automatic linear adjustment.

Straight Racks

Straight racks are available in standard lengths of 0.5, 1.0, 2.0 and 3 metres machined to 20* PA with pitch range 1 Mod. to 8 Mod. These are designed to combine with the standard spur gears to provide low cost conversion of rotary to linear motion.

Precision Construction for Demanding Applications

Manufactured from high-grade alloy steel, this freewheel clutch employs a sprag-type mechanism for consistent engagement and disengagement. Its black oxide coating ensures long-lasting durability, while grease lubrication maintains performance under demanding operational conditions.

Versatile Installation and Operational Flexibility

The clutch supports both keyway and press fit mounting, enabling compatibility with various shaft setups in conveyor and indexing applications. Its bi-directional torque transmission and P6 precision rating allow for reliable operation in systems requiring frequent starts and stops.

Optimal Sealing and Performance

Equipped with metal shielded seals, the clutch is safeguarded against contamination while retaining lubricants. Its 3200 Nm load capacity and 2500 RPM speed limit make it ideally suited for high-load, moderate-speed operations across multiple industrial sectors.

FAQs of Cross and Morse Freewheel Clutch:

Q: How is the Cross and Morse Freewheel Clutch installed in conveyor systems?

A: The clutch can be mounted using either a keyway or press fit method, depending on the shaft design of your conveyor system. Both installation types ensure a secure fit and reliable torque transmission for various industrial setups.Q: What are the benefits of using a sprag-type freewheel clutch in indexing and overrunning applications?

A: Sprag-type freewheel clutches provide precise motion control and quick engagement or disengagement, which is essential for accurate indexing and overrunning operations. This design also minimizes wear and ensures smooth transitions, increasing system longevity.Q: When should grease lubrication be maintained for this freewheel clutch?

A: Grease lubrication should be checked periodically depending on the operational environment and load. Regular maintenance ensures optimal clutch performance and protects internal components against wear and contamination.Q: Where can this clutch be effectively applied beyond conveyors?

A: Aside from conveyor drives, this freewheel clutch is suitable for automated indexing systems, overrunning devices in heavy machinery, and material handling equipment due to its high load capacity and bi-directional torque transmission.Q: What is the process for selecting the correct clutch size for a specific application?

A: To select the right clutch, consider the required bore and outside diameter, load capacity, limiting speed, and shaft mounting type. Matching these parameters with your applications requirements ensures reliable and efficient operation.Q: How does the bi-directional torque transmission benefit multi-directional conveyor systems?

A: Bi-directional torque transmission allows the clutch to engage and disengage in both rotational directions, providing flexibility for conveyor systems that require reversibility or multi-directional indexing.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Clutches & Brakes Category

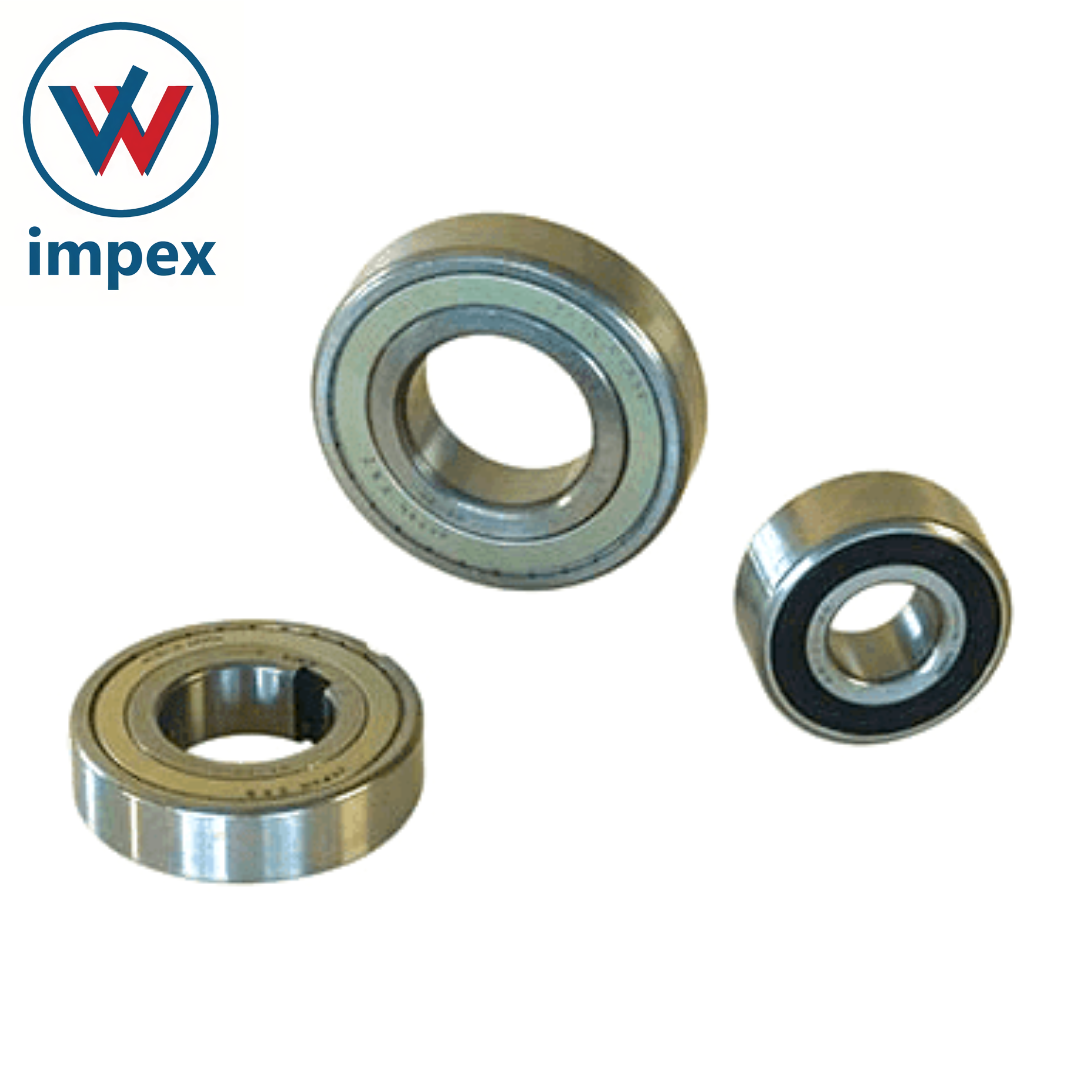

Aetna Clutch Release Bearing

Price 7950 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Number Of Rows : Other, 2

Lubrication Type : Other, Prelubricated Grease

Structure : Radial Double Row

GMN Freewheel Clutch

Price 18900 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Number Of Rows : Other, Single

Lubrication Type : Other, Grease Lubrication

Structure : Single Row Cylindrical Roller Freewheel

Binder Brakes and Clutches

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Number Of Rows : Other, Single

Lubrication Type : Grease

Structure : Disc Type

Coremo Brakes and Clutches

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special Alloy Steel

Number Of Rows : Other, Single

Lubrication Type : Other, Grease / Oil lubricated

Structure : Brake and Clutch Assembly

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry