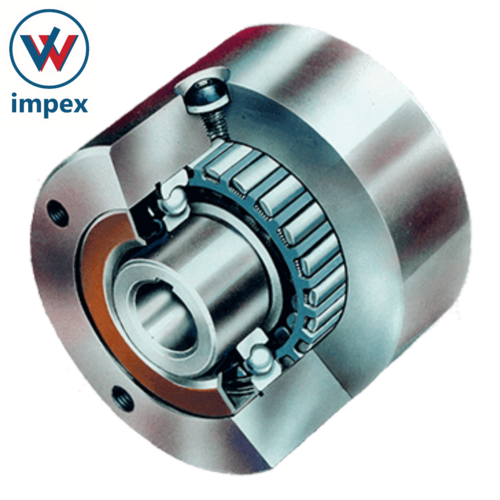

Stieber Freewheels Clutch

Stieber Freewheels Clutch Specification

- Thickness

- 17 mm

- Inside Diameter

- 25 mm

- Retainer

- Steel

- Cage Material

- Steel

- Lubrication Type

- Grease Lubricated

- Precision Rating

- ISO Class 6

- Bearing Type

- Freewheel Clutch Bearing

- Material

- Chrome steel

- Structure

- Clutch Freewheel

- Seals Type

- Metal Sealed

- Number Of Rows

- Single Row

- Bore Size

- 25 mm

- Outside Diameter

- 62 mm

- Limiting Speed

- 5000 RPM

- Load Capacity

- 3150 N

- Torque Capacity

- 42 Nm

- Model Number

- FS 25

- Temperature Range

- -20°C to +100°C

- Application

- Backstop, Indexing, Overrunning

- Weight

- 0.32 kg

- Finish Type

- Anti-corrosive

- Mounting Type

- Shaft Mounted

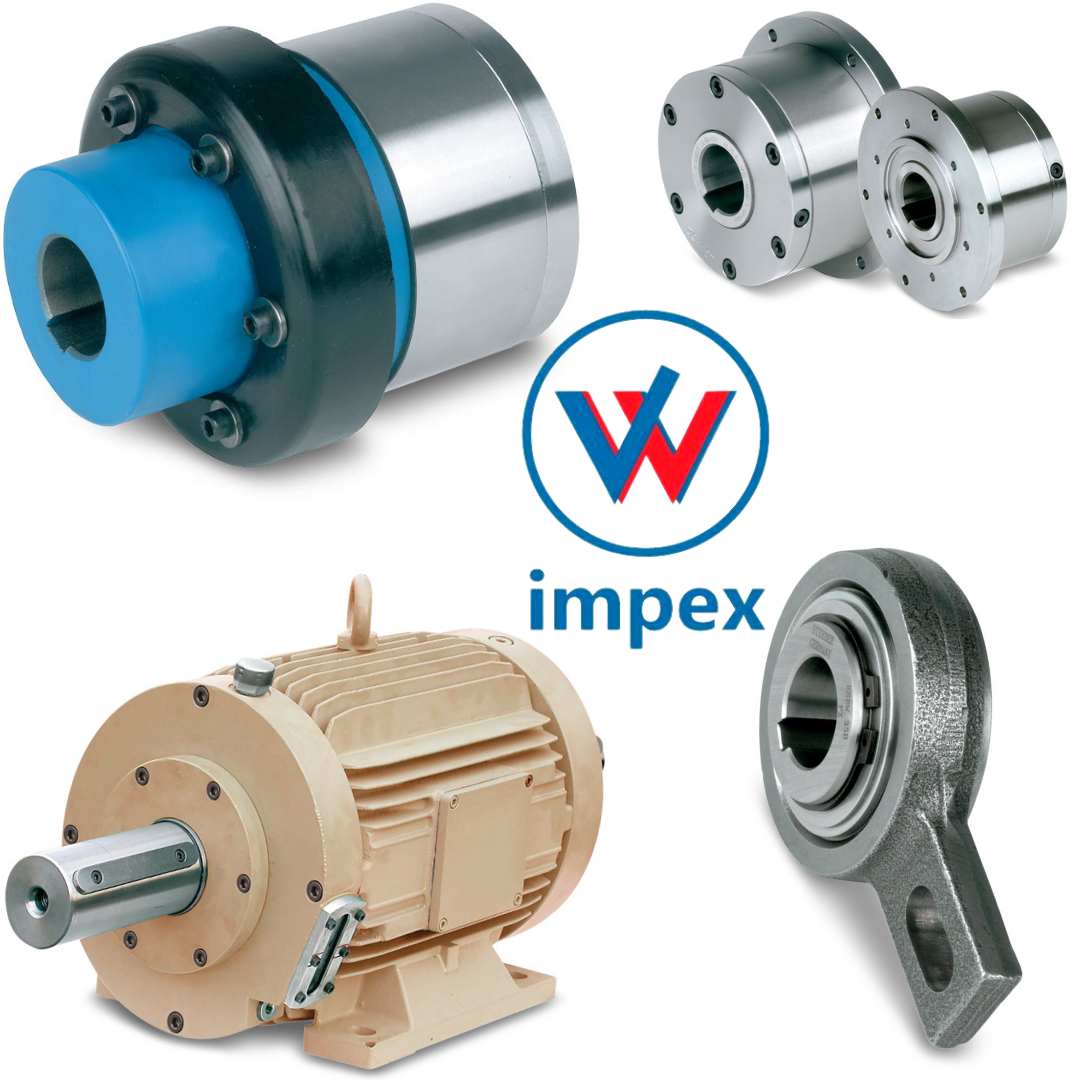

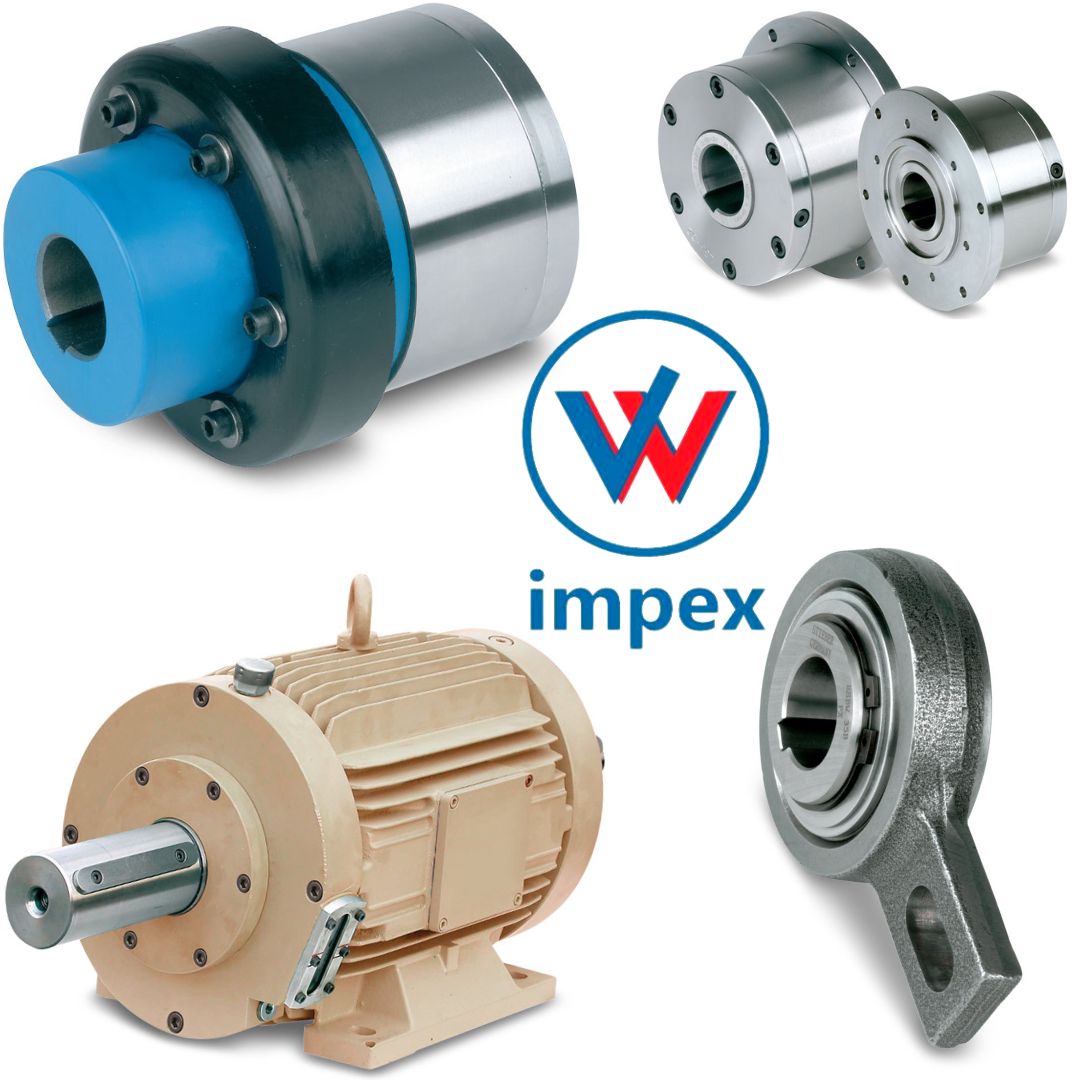

About Stieber Freewheels Clutch

Stieber Freewheels Clutch |

Type CSK is a sprag type freewheel integrated into a 62 series ball bearing (except sizes 8 and 40). It is bearing supported, delivered grease lubricated and protected against dust of more than 0.3mm. The use of additional "Nilos" type seals is recommended especially when the working temperature exceeds 50 degree C. Oil bath lubrication is also possible.

All the CSK versions are equipped with "Form chromed" sprags. The process increases several times the overrunning life time.

Torque transmission is ensured by a press fit assembly into a rigid outer housing with N6 tolerance, and onto a shaft with n6 tolerance. The initial bearing radial clearance is set at C5, and is reduced if using the press fit as specified.

Reliable Performance and Design

The FS 25 clutch leverages advanced freewheel technology and a single-row structure for effective motion control. Designed to endure high rotational speeds and heavy loads, it is built from quality chrome steel with a steel retainer and anti-corrosive treatment, ensuring longevity and consistent operation.

Versatile Industrial Applications

Stieber Freewheels FS 25 serves essential roles in machinery requiring backstop, indexing, and overrunning functions. Its high-load capacity and broad temperature tolerance make it suitable for manufacturing, automation, and conveyance systems, providing reliable torque handling and motion precision.

FAQs of Stieber Freewheels Clutch:

Q: How does the FS 25 Freewheels Clutch enhance machinery performance?

A: The FS 25 clutch provides precise torque transmission and prevents reverse rotation, ensuring smooth and reliable operation in applications such as backstop, indexing, and overrunning.Q: What benefits does the anti-corrosive finish offer in industrial settings?

A: The anti-corrosive finish protects the clutch from environmental wear and moisture, significantly extending its lifespan and maintaining consistent functionality in harsh conditions.Q: Where can the Stieber Freewheels FS 25 clutch be installed?

A: This clutch is shaft-mounted and can be integrated into various industrial machinery, including conveyors, automation systems, and equipment needing rotational motion control.Q: When should I use a freewheel clutch like the FS 25?

A: A freewheel clutch is ideal when machinery requires prevention of reverse rotation, safe overrunning operations, or accurate indexing, particularly in manufacturing or material handling setups.Q: What is the process for maintaining the FS 25 clutch?

A: Regular inspection for wear, checking lubrication (grease type), and ensuring seals and casing integrity form the standard maintenance routine for optimal clutch performance.Q: What is the application advantage of the metal sealed design?

A: Metal seals safeguard internal components from contaminants and mechanical wear, improving reliability and reducing maintenance frequency, especially in high-demand environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

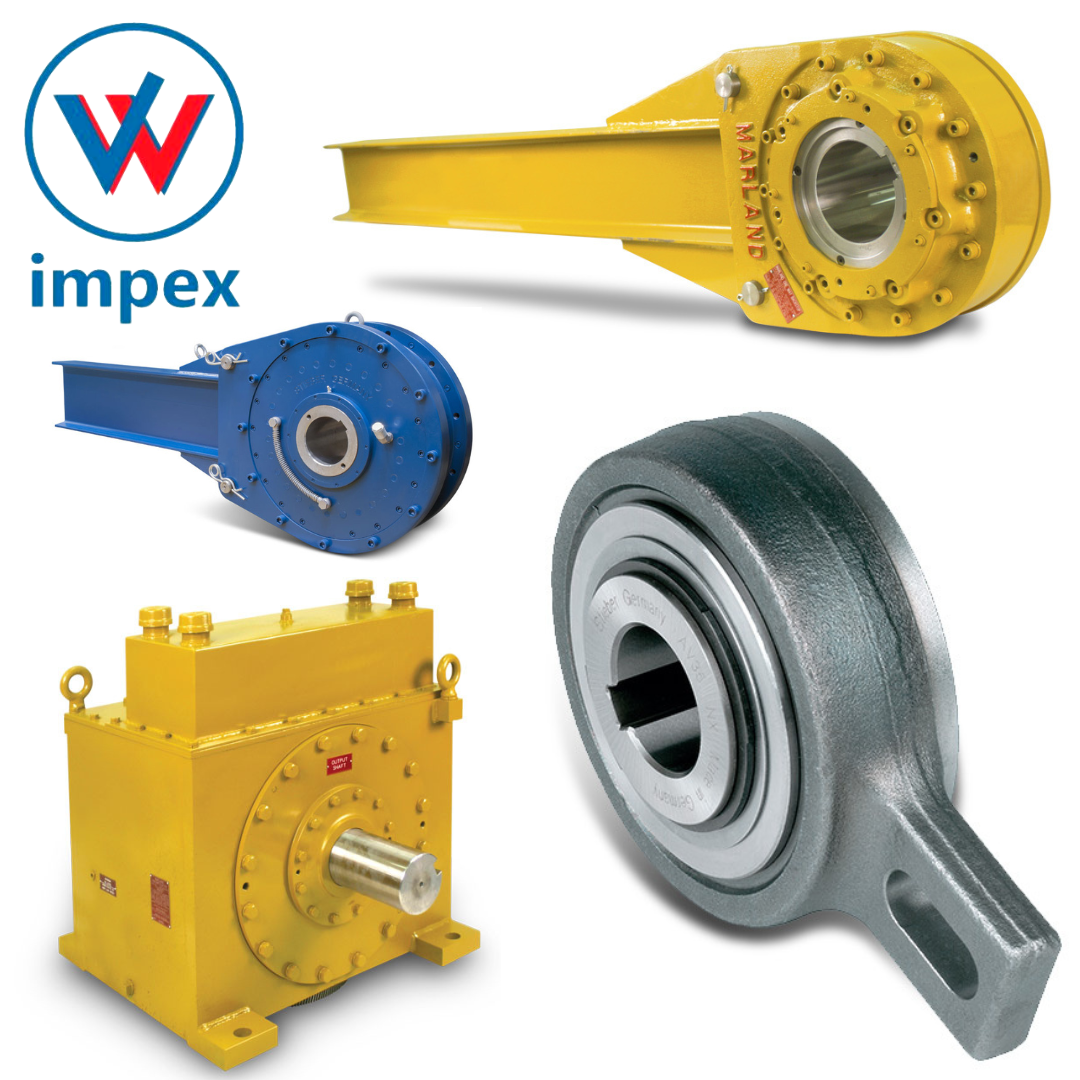

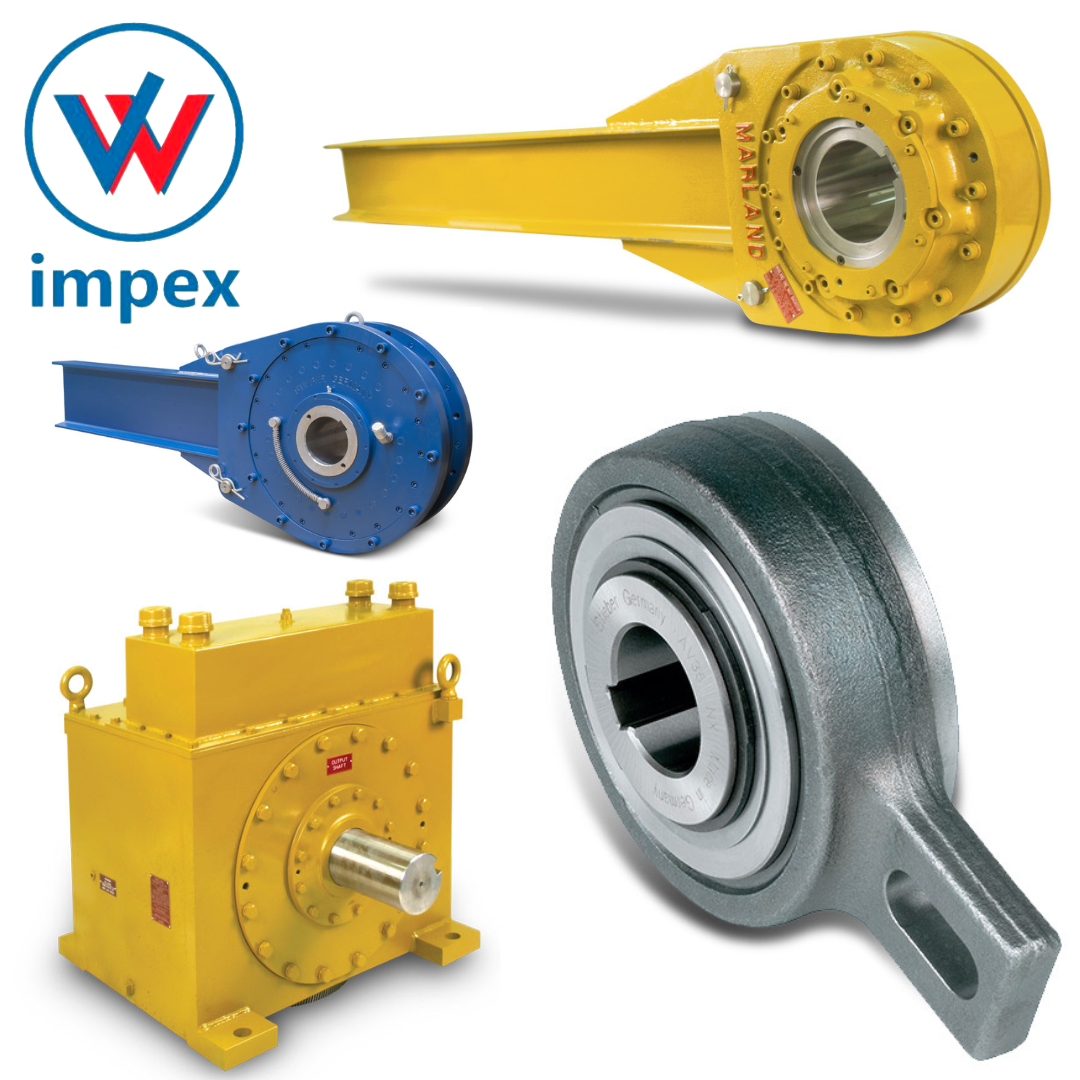

More Products in Clutches & Brakes Category

Free Wheel Clutches Bearing

Price 2000

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Inside Diameter : 35 mm

Bore Size : 35 mm

Load Capacity : 7500 N

Cross and Morse Freewheel Clutch

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Inside Diameter : 35 mm

Bore Size : 35 mm

Load Capacity : 3200 Nm

Coremo Brakes and Clutches

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special Alloy Steel

Inside Diameter : Customizable

Bore Size : Customizable

Load Capacity : Heavy Duty

Binder Brakes and Clutches

Price 65000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel

Inside Diameter : 25 mm

Bore Size : 25 mm

Load Capacity : Heavy Duty

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry