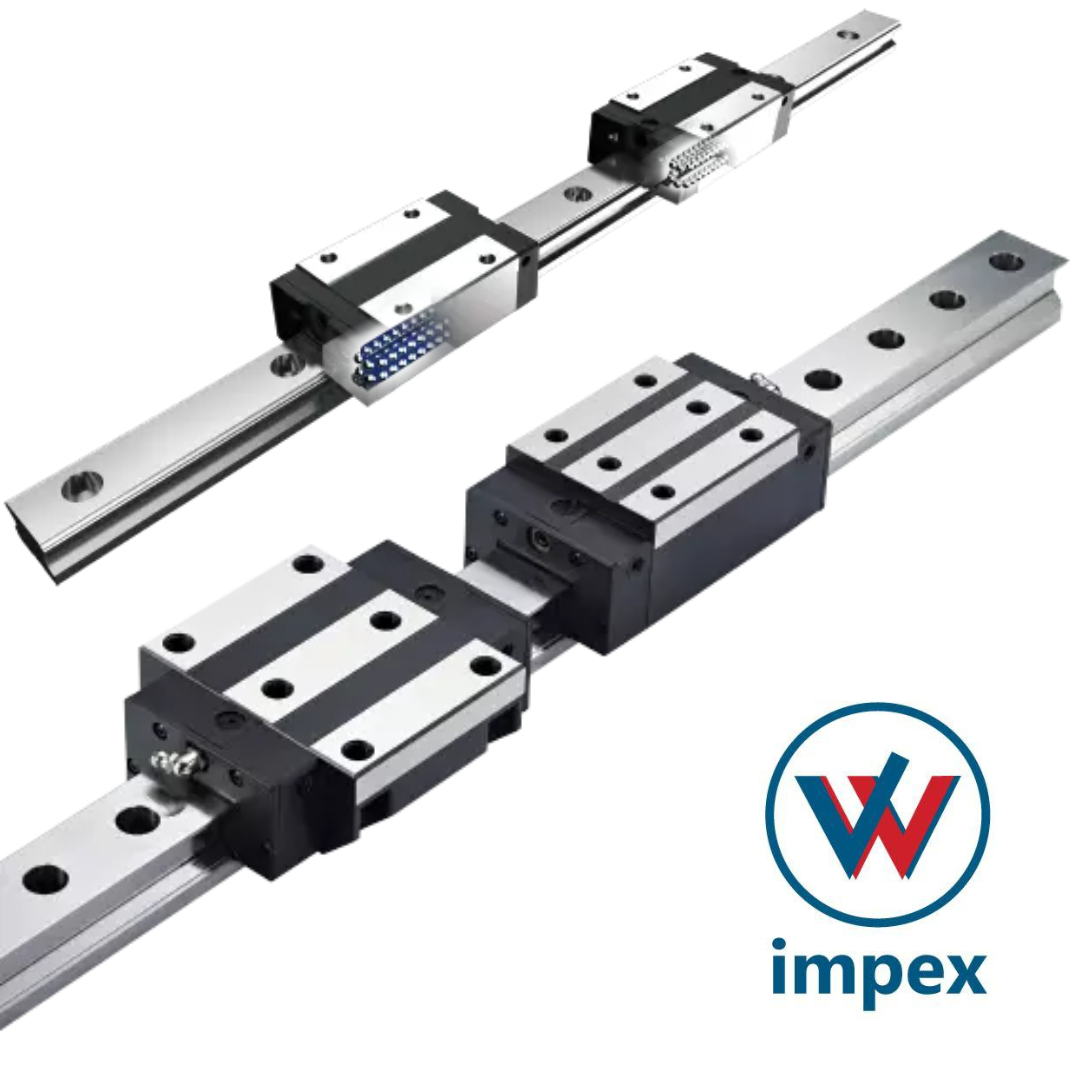

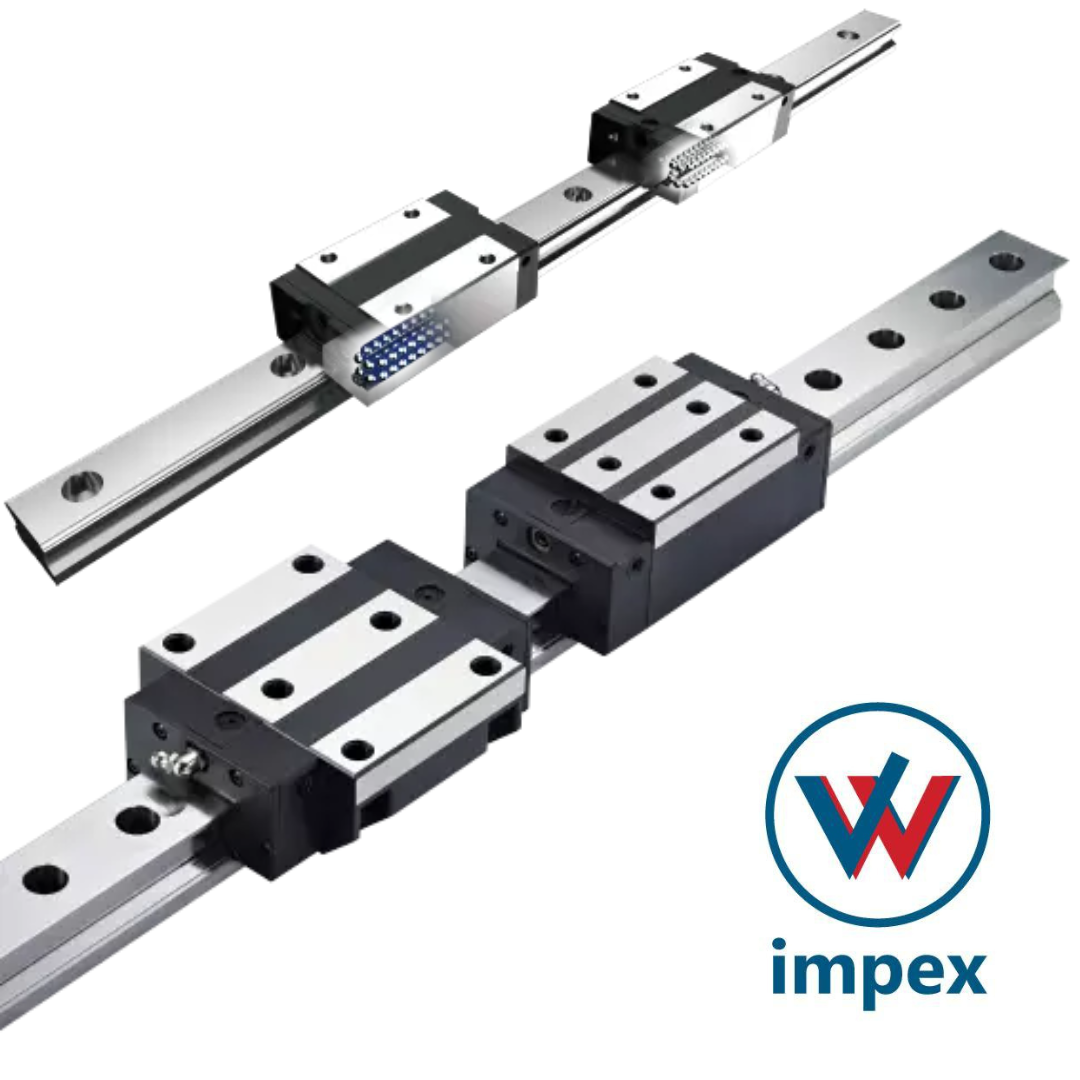

PMI Linear Motion System

PMI Linear Motion System Specification

- Thickness

- 12 mm, 15 mm, 20 mm

- Weight

- 1.5 kg/m (rail only)

- Material

- Aluminium, Stainless Steel

- Ball Bearing Type

- Recirculating Ball Bearing

- Roller Bearing Type

- Cylindrical Roller Bearing

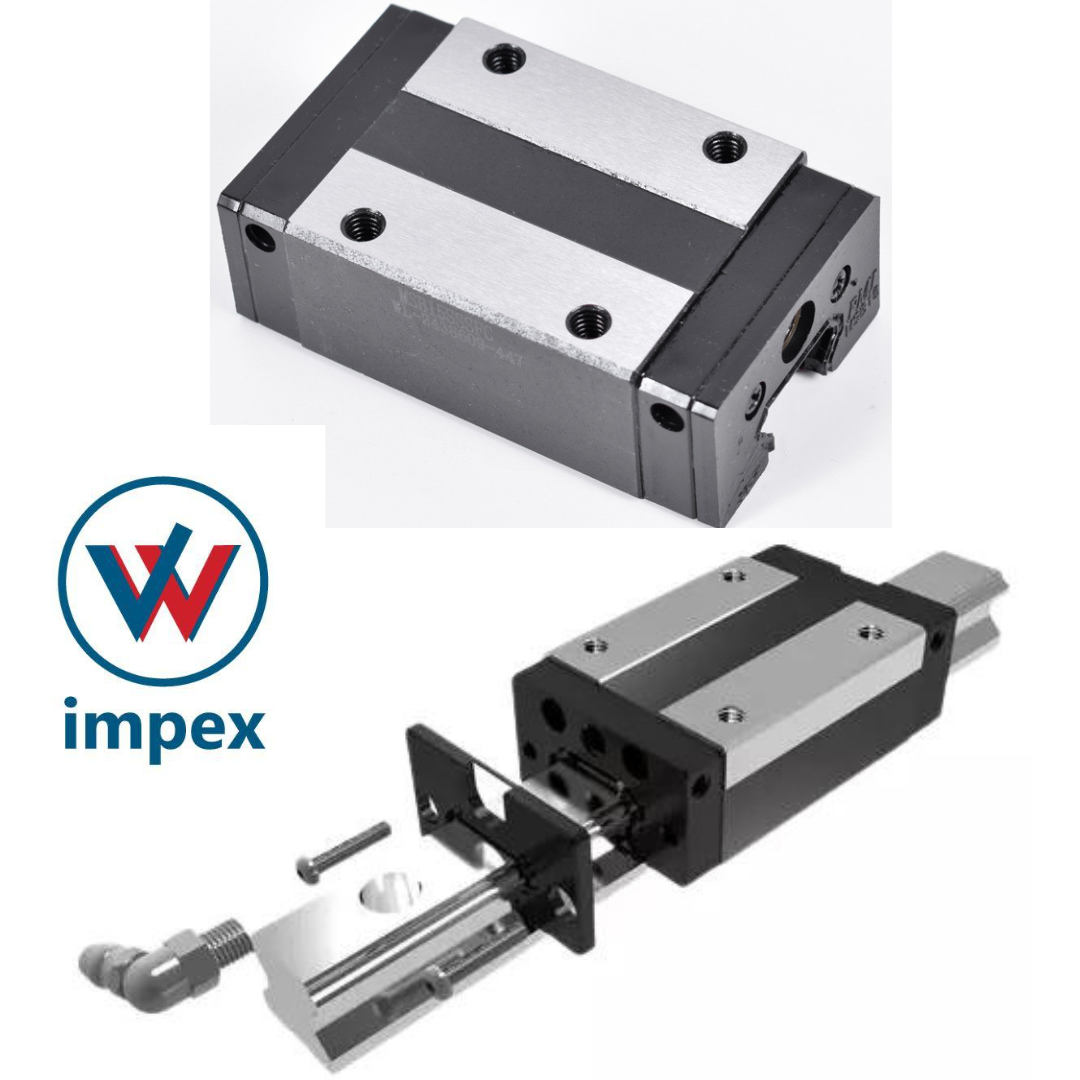

- Bushes Type

- Linear Motion Bushes

- Structure

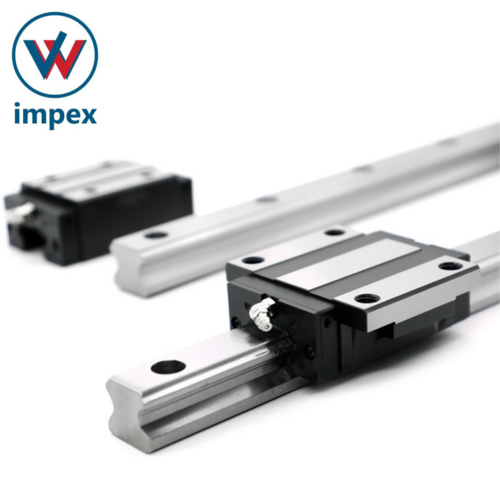

- Guideway Rail with Carriage

- Seals Type

- Double Lip Seals

- Number Of Rows

- 4

- Bore Size

- 16 mm, 20 mm, 25 mm (customizable)

- Outside Diameter

- 28 mm to 80 mm

- Limiting Speed

- Up to 80 m/min

- Load Capacity

- Maximum 18.7 kN

- Inner Diameter

- 16 mm to 50 mm

- Interchangeability

- Carriage and Rail are Fully Interchangeable

- Mounting Method

- Bolt-on and Clamping

- Lubrication Method

- Grease or Oil

- Application

- CNC Machines, Automation, Industrial Equipment, Robotics

- Corrosion Resistance

- Available with or without surface treatment

- Noise Level

- Low Noise Operation (<65 dB)

- Precision Class

- C, H, P, SP (customizable precision)

- Operating Temperature Range

- -40°C to +80°C

- Stroke Length

- Available up to 4000 mm

About PMI Linear Motion System

PMI Linear Motion System was established in 1990. Its highly involved in manufacturing of ball screws, linear guideway and mono stage, which is the critical component of precision machinery and mainly applied to Machine Tool, Electric Discharging Machine, Cutting Wire Machine, Plastics Injection Machine, Semi-conductor Equipment, Precision Orientation Equipment and other Equipments and machines.

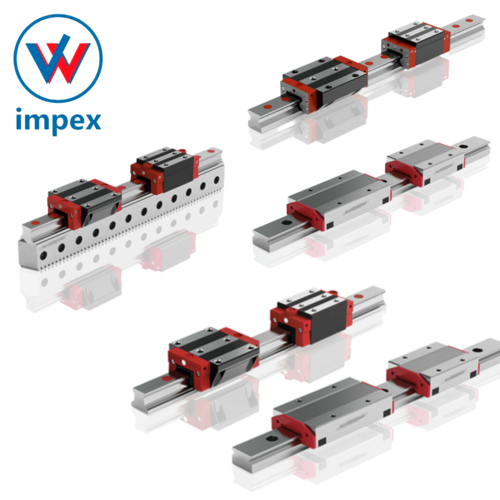

MSA Series : MSA series can achieve a well balanced pre-load for increasing rigidity in four directions while keeping a low frictional resistance. This is especially suit to high precision and high rigidity required motion.

MSB Series : MSB series can achieve a well balanced pre-load for increasing rigidity in four directions while keeping a low frictional resistance. This is especially suit to high precision and high rigidity required motion.

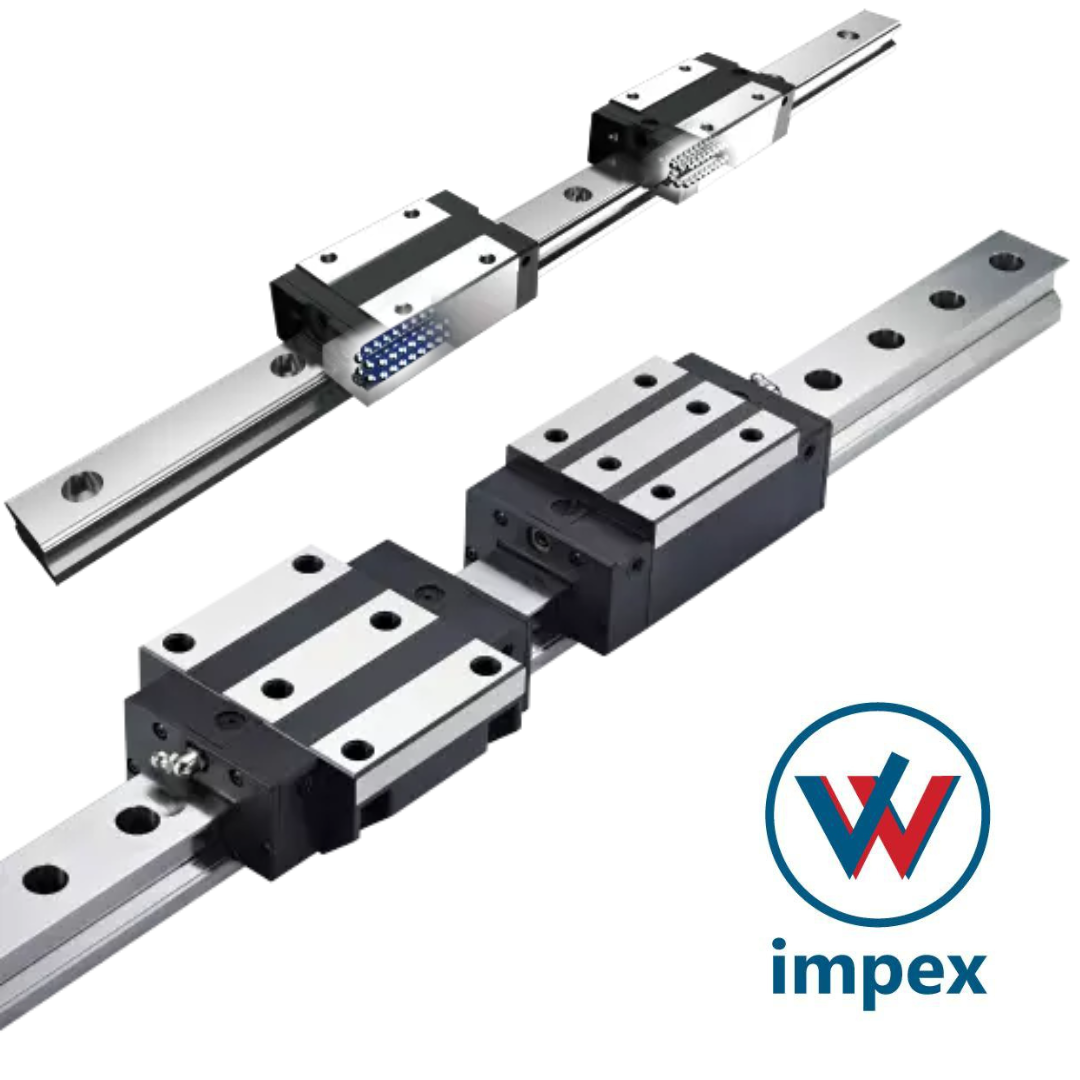

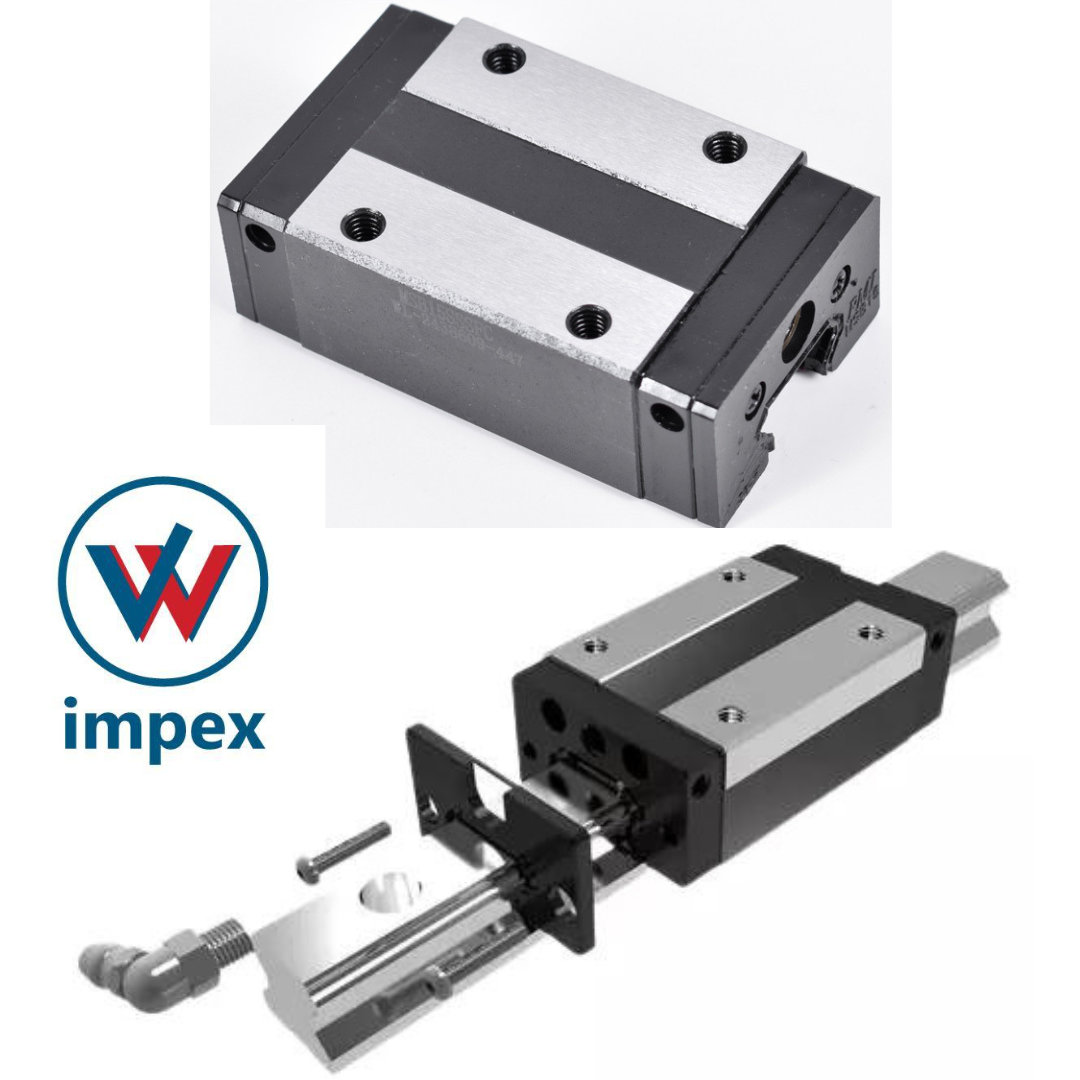

MSR Series The full roller type linear guideway, MSR series, equip with rollers instead of the ball, and therefore the MSR series can provide higher rigidity and loading than the normal type with the same size. Especially suit for the requests of high accuracy, heavy load and high rigidity.

MSC Series : MSC stows with Gothic-arch groove and designed to contact angle of 45 degree which enables it to bear an equal load in radial, reversed radial and lateral directions. Furthermore, ultra compact and low friction resistance design is suit to compact equipment. The lubrication route makes the lubricant evenly distribute in each circulation loop.

SME Series The ball chain type linear guideway, SME series, equip with the patent of ball chain design can make the vement smooth and stability, especially suit for the requests of high speed, high accuracy.

SMR Series The roller chain type linear guideway, SMR series, equip with rollers instead of the ball, and therefore the SMR series can provide higher rigidity and loading than the normal type with the same size. Besides, the patent of roller chain design can make the movement smooth and stability, especially suit for the requests of high accuracy, heavy load and high rigidity.

Precision Tailored for Your Industry

Choose from precision classes C, H, P, or SP, enabling you to match performance with application needs. Each class offers varying tolerances suitable for tasks ranging from general automation to high-accuracy CNC machining. Customization options extend to bore size and surface treatment for an optimal fit.

Versatile Installation and Maintenance

Benefit from bolt-on or clamping mounting methods, allowing straightforward integration into both new and existing equipment. Grease or oil lubrication ensures smooth operation and extends lifespan. Double lip seals protect against contaminants, minimizing maintenance requirements.

Engineered for Durability and Performance

Constructed with aluminium or stainless steel, PMI systems resist wear and corrosion, even under extreme temperatures. Operating at low noise levels (<65 dB) enhances their suitability for sensitive environments. Their robust structure and high load capacity accommodate demanding industrial and robotic automation tasks.

FAQs of PMI Linear Motion System:

Q: How can I select the appropriate precision class for my linear motion system?

A: The choice of precision class (C, H, P, SP) depends on your applications accuracy requirements. For general industrial tasks, C or H is suitable, while CNC machining and robotics may benefit from P or SP classes for higher precision. Consult our specialists to match precision with your performance needs.Q: What are the installation options for the PMI Linear Motion System?

A: This system supports both bolt-on and clamping mounting methods, providing flexibility during setup. It can be integrated seamlessly into new builds or retrofitted into existing machines, minimizing installation time and maximizing compatibility.Q: When should I use surface-treated (corrosion-resistant) rails and carriages?

A: Corrosion-resistant surface treatments are recommended for environments exposed to moisture, chemicals, or corrosive agentssuch as food processing, marine, or certain automated manufacturing environments. Specify this option when ordering if corrosion resistance is a priority.Q: Where is the PMI Linear Motion System typically applied?

A: These systems are widely used in CNC machines, automation lines, industrial machinery, and advanced robotics. Their customizable features allow adaptation across diverse industries requiring precise, reliable linear movement.Q: How is lubrication managed, and what impact does that have on system longevity?

A: Choose between grease or oil lubrication based on maintenance schedules and operational demands. Regular lubrication minimizes wear and ensures long-term reliability, while the double lip seals retain lubricant and block contaminants.Q: What are the main benefits of interchangeability between rail and carriage?

A: Full interchangeability allows for easy replacement or upgrading of either the carriage or rail, reducing downtime and maintenance costs. This modularity is especially valuable in fast-paced production environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Linear Motion Category

Ewellix Linear Guides

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Stainless Steel

Weight : 0.29 kg

Outside Diameter : 16 mm

Seals Type : Doublelip Seals

Schneeberger Linear Guide

Price 10000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Highquality Steel

Weight : 1.5 kg/m

Outside Diameter : 26 mm

Seals Type : Doublelip Seals

NB Linear Bearing

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome Steel, Stainless Steel

Weight : 50 g to 700 g

Outside Diameter : 15 mm to 80 mm

Seals Type : Rubber Seals

Shuton Precision Ball Screws

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Alloy Steel, Hardened and Ground

Weight : Depends on Size and Model

Outside Diameter : Customized per application

Seals Type : Labyrinth and Wiper Seals

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry