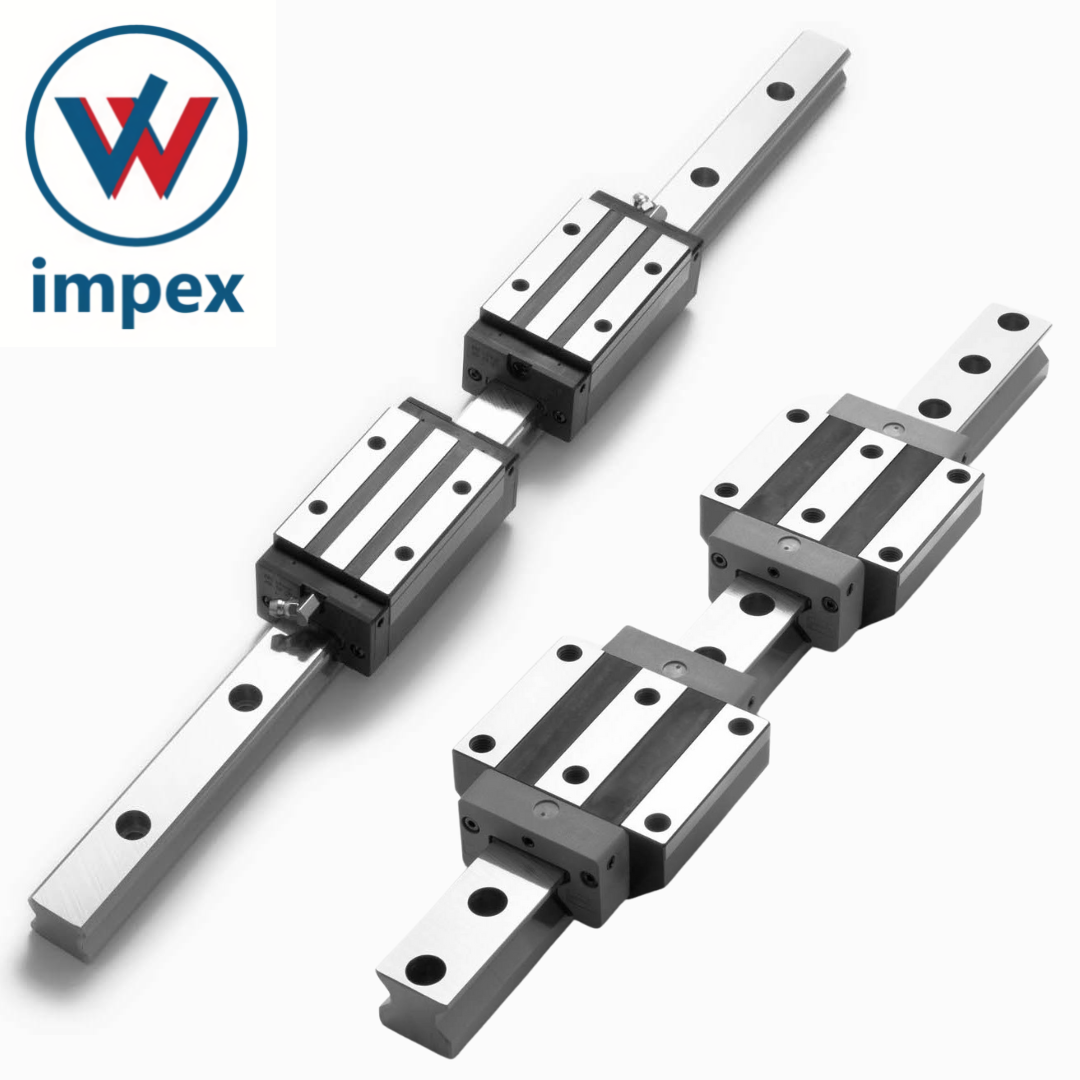

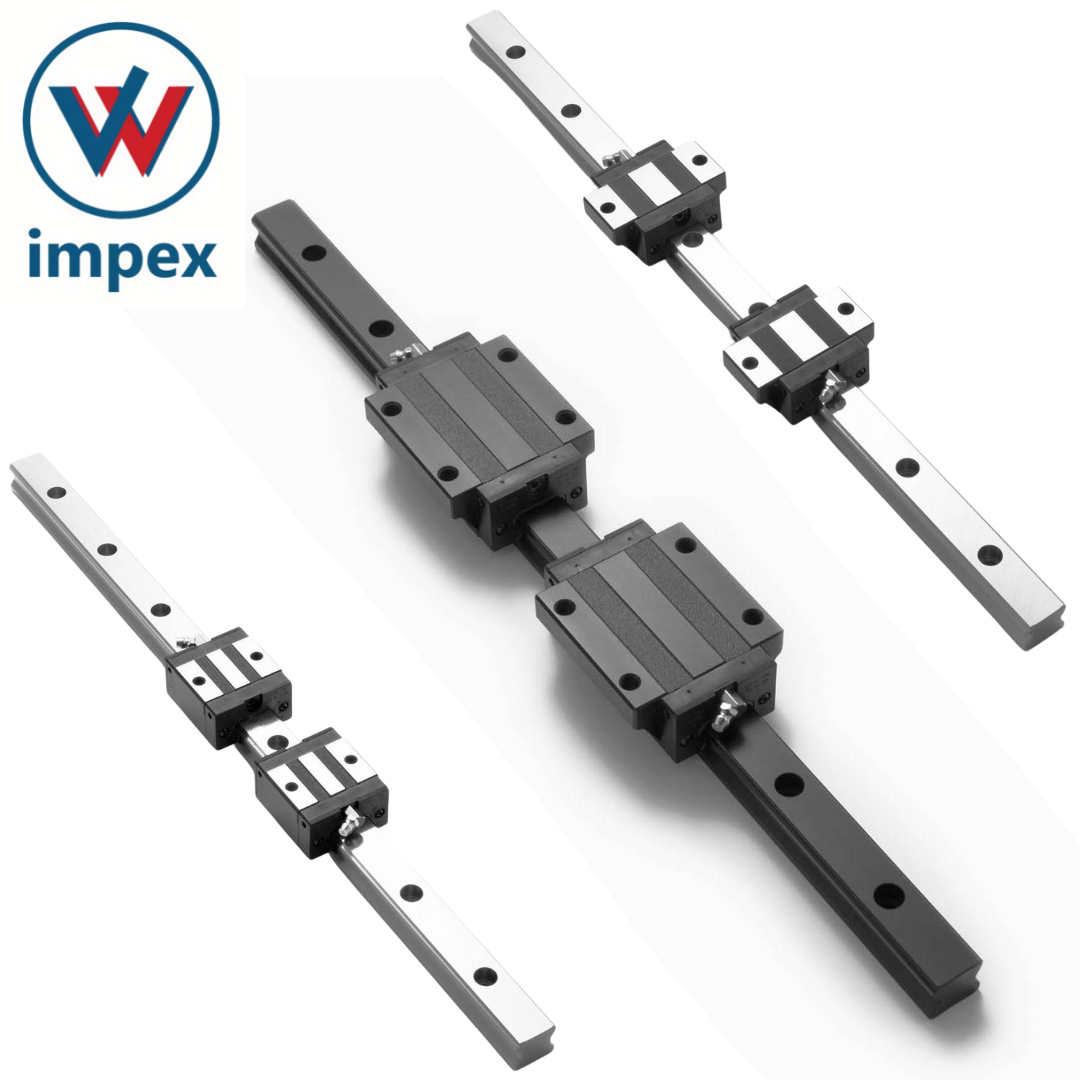

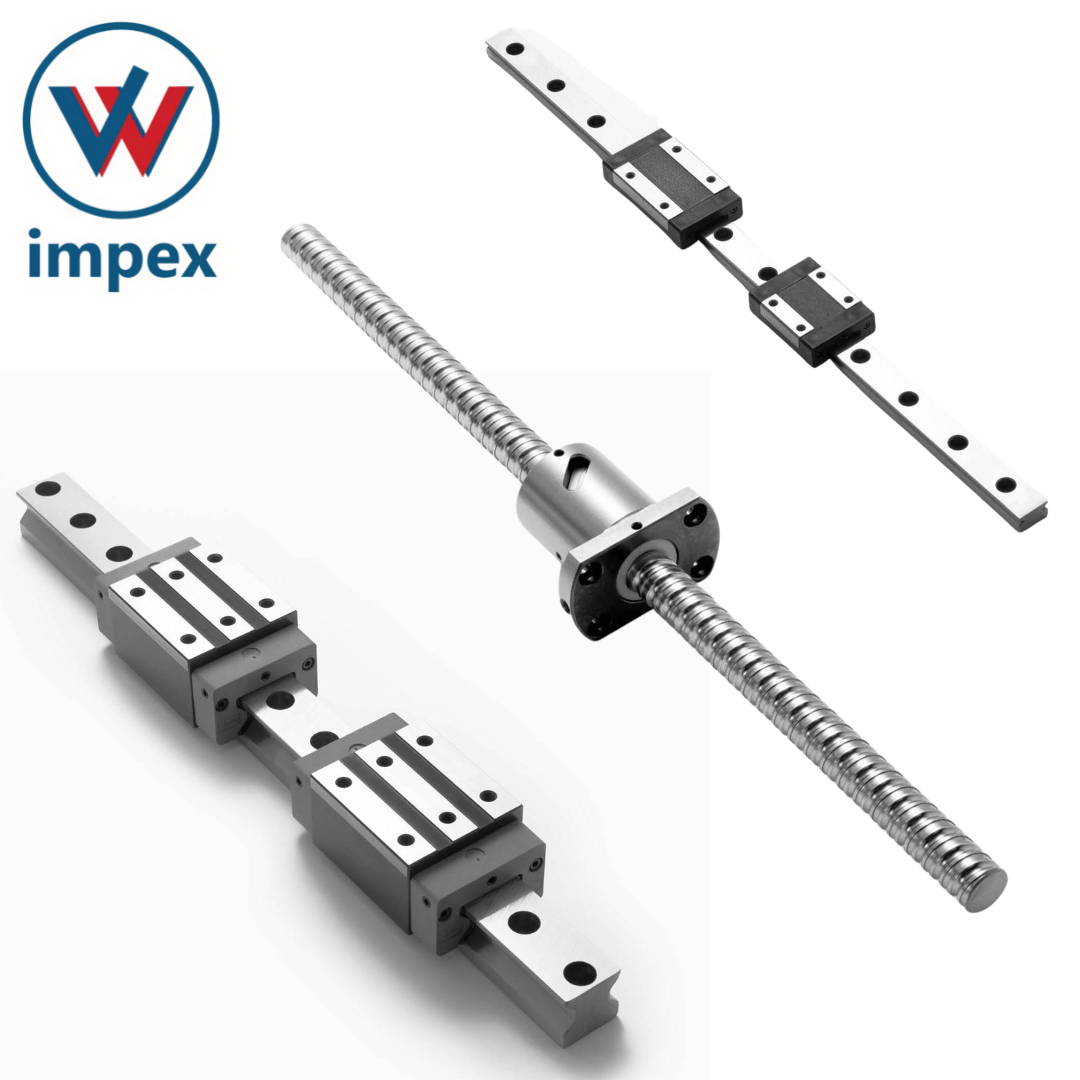

SBC Linear Motion Guide

Price 10000 INR/ Piece

SBC Linear Motion Guide Specification

- Thickness

- 20 mm

- Weight

- 1.5 kg

- Material

- High-Grade Alloy Steel

- Ball Bearing Type

- Precision Steel Ball

- Bushes Type

- Polymer Composite

- Structure

- Four-row Angular Contact

- Seals Type

- End Seals

- Number Of Rows

- 4

- Bore Size

- 20 mm

- Outside Diameter

- 57 mm

- Limiting Speed

- Up to 5 m/s

- Load Capacity

- 35 kN

- Inner Diameter

- 20 mm

- Shock Resistance

- High

- Preload Class

- Standard or Customizable

- Mounting

- Top and Side Mount

- Accuracy Grade

- H (High Precision)

- Rail Type

- Profiled Linear Rail

- Operating Temperature Range

- -10°C to +80°C

- Carriage Type

- Standard Carriage

- Lubrication Type

- Grease or Oil lubrication

- Application

- CNC Machines, Automation Equipment, Industrial Robotics

- Noise Level

- Low Noise Operation

- Surface Treatment

- Anti-corrosion Coating

- Guide Length

- Customized up to 4000 mm

About SBC Linear Motion Guide

SBC Linear Co., Ltd. has been providing linear rail systems to over 25 countries as the first developer and manufacturer of Linear rail systems in Korea.

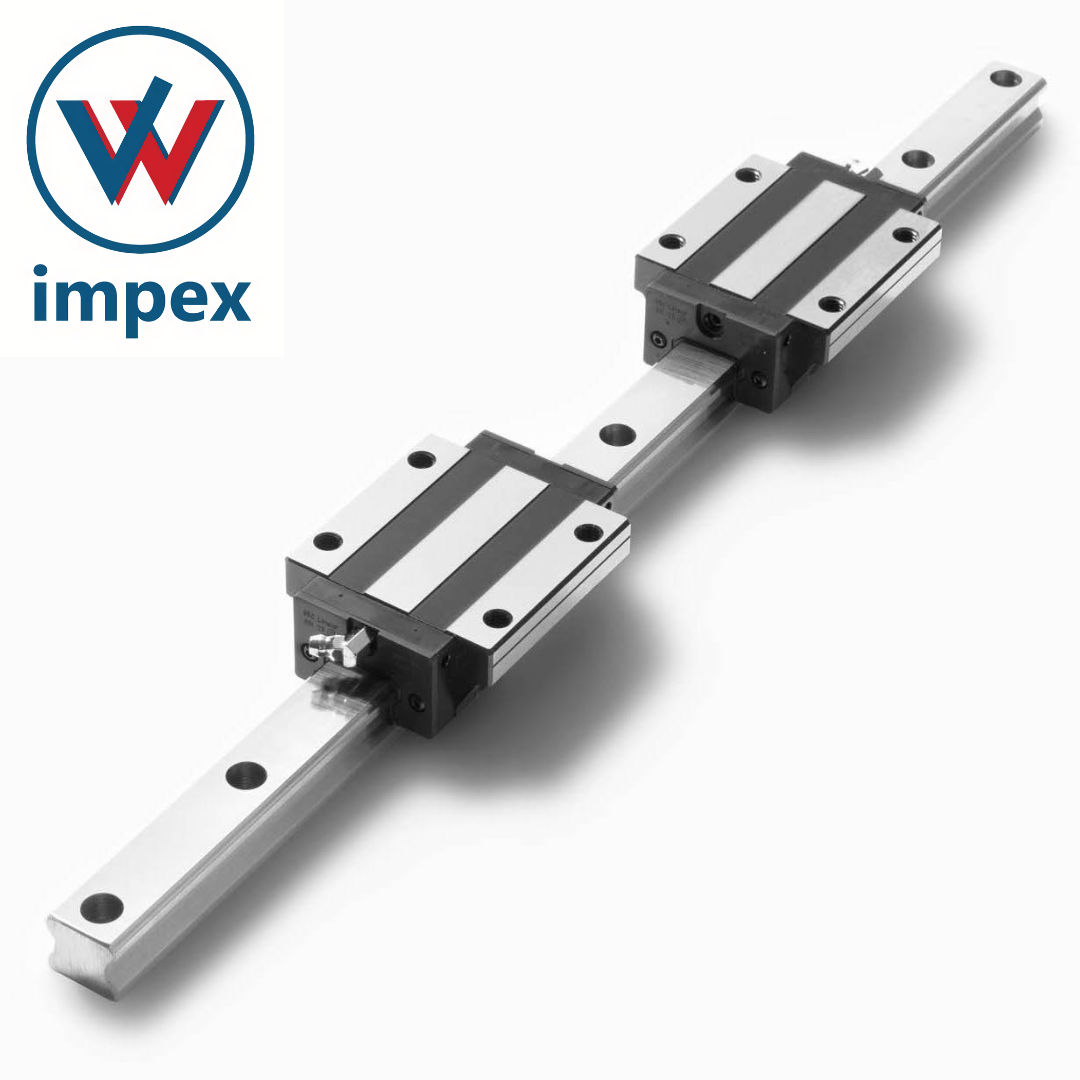

SBC Linearguide blocksprovide high capacity, low friction guidance of payloads. With 4 rows of recirculating balls engaged in a precision ground rail, these bearings provide load capacity in all directions.

- Industry standard sizes 15 to 65 with load capacities from 4.5kN to 320kN (1000lbs to 72000lbs)

- Rail lengths to 4000mm with splicing (butt joints) availableto makelonger lengths

- Each block has options for seals, scrapers, and maintenance free lubrication

- Corrosion resistant options for Raydent, TDC, and TDNC are also available

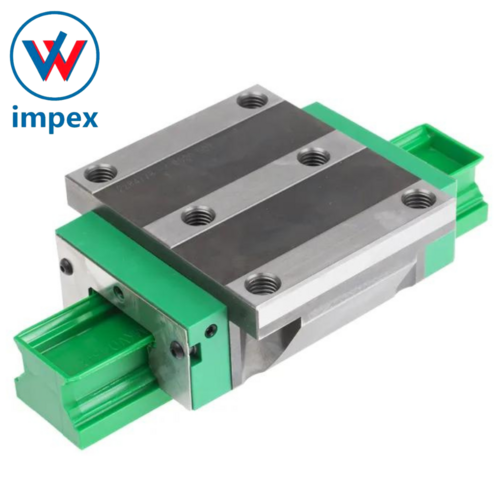

SBI High load type

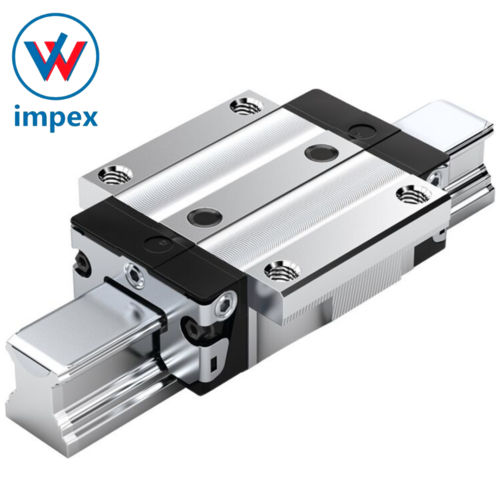

SBG Standard type

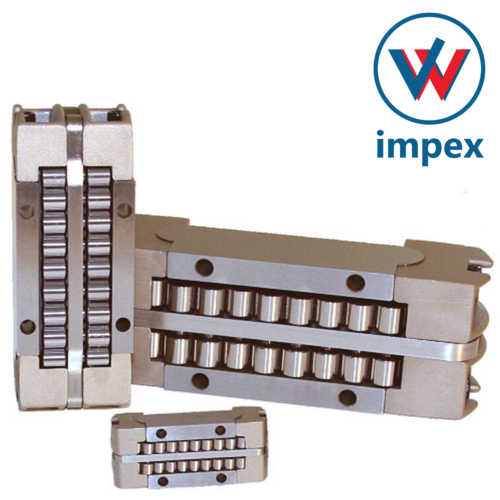

SPG/SPS Spacer type

Miniature type

SBI FL / FLL

SBI HL

SBI SL / SLL

SBI CL

SBG FL / FLL

SBG SL / SLL

SBS SL / SV

SBS SLL

SBC Linearguiderailsare designed to mate with the SBC linear guide blocks.

- Available are rail sizes15, 20, 25, 35, 45, 55,and65

- Available are standard lengths ranging from 160 mm to 4000 mm

We also cut rail to your specific size when requested.

| Design | Standard |

| Usage/Application | Rail Block |

| Size | 15-65 MM |

| Packing Type | EACH |

| Brand | SBC |

| Model Number | SBG-20-25-30-35-40-45-50 |

| Material | SBC Linear Rail System |

| Length | Standard |

| Packaging Type | Single |

Engineered for Demanding Applications

Designed for use in CNC machines, industrial robotics, and automation equipment, the SBC Linear Motion Guide ensures dependable performance under challenging conditions. Its four-row bearing configuration delivers enhanced stability and robust shock resistance, optimizing system longevity and precision.

Customizable Dimensions and Mounting

Available rail lengths can be tailored up to 4000 mm, making the guide exceptionally versatile for a range of industrial uses. With both top and side mounting options, its integration into varied assemblies is seamless and flexible, supporting innovative engineering requirements.

Superior Materials and Anti-Corrosion Coating

Manufactured from high-grade alloy steel and coated for superior anti-corrosion protection, this guide delivers long-lasting performance in environments where durability is paramount. Polymeric composite bushes and precision steel balls further support smooth, efficient motion and operational reliability.

FAQs of SBC Linear Motion Guide:

Q: How can I select the appropriate rail length for my SBC Linear Motion Guide?

A: The rail length for your SBC Linear Motion Guide can be customized up to 4000 mm based on your machine specifications. Please provide your required length during the consultation process to ensure the guide meets your installation and functional requirements.Q: What are the benefits of the four-row angular contact structure in this guide?

A: The four-row angular contact structure ensures high rigidity, increased load capacity (up to 35 kN), and superior shock resistance. This design delivers optimal stability, especially for demanding CNC and automation applications.Q: When should I consider using standard versus customizable preload classes?

A: Standard preload is suitable for most general applications where typical accuracy and rigidity are required. Opt for a customizable preload class if your application demands unique precision or stiffness, such as in high-speed or heavy-load operations.Q: Where is the SBC Linear Motion Guide typically used?

A: This linear motion guide is widely employed in CNC machines, automation equipment, and industrial robotics due to its robust construction, precise motion, and adaptability to various mounting requirements.Q: What is the recommended type of lubrication and how often should it be applied?

A: The guide supports both grease and oil lubrication. For optimum performance and longevity, apply lubrication at intervals specified in your operation manualfrequency may vary based on usage intensity and environmental conditions.Q: How does the anti-corrosion coating enhance the performance of the guide?

A: The anti-corrosion coating protects the high-grade alloy steel from rust and surface degradation, particularly in environments with moisture or chemical exposure, thereby extending the guides operational lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Linear Motion Category

Ewellix Linear Guides

Price 4000 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Stainless Steel

Seals Type : Doublelip Seals

Structure : Linear Guide Rail with Runner Block

Load Capacity : 3400 N

Tychoway Linear Roller Bearings

Price 25000 INR

Minimum Order Quantity : 1 Piece

Material : Alloy Steel

Seals Type : Double Sealed

Structure : Supported Rail

Load Capacity : 2000 N

Rexroth Linear Motion Guide Way

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

INA Linear Rail Guide

Price 10000 INR

Minimum Order Quantity : 1 Piece

Material : Steel

Seals Type : Highperformance seals

Structure : Linear rail guide with block carriage

Load Capacity : High

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry