Osborn Cam Followers And Load Runners

Price 8500 INR/ Piece

Osborn Cam Followers And Load Runners Specification

- Thickness

- Standard (varies by model; typically 10 mm to 35 mm)

- Retainer

- Steel

- Precision Rating

- P0, P6

- Lubrication Type

- Factory Lubricated, Relubrication Possible

- Inside Diameter

- 6 mm to 90 mm

- Cage Material

- Steel

- Bearing Type

- Cam Follower / Load Runner

- Material

- High Grade Alloy Steel

- Structure

- Stud Type, Yoke Type

- Seals Type

- Double Seal

- Number Of Rows

- Single Row

- Bore Size

- 6 mm to 90 mm (varies by model)

- Outside Diameter

- 16 mm to 150 mm (varies by model)

- Limiting Speed

- Up to 6000 RPM (varies by size)

- Load Capacity

- High Load Bearing (Specific capacity depends on size/model)

- Operating Temperature Range

- -30°C to +150°C

- Application

- Material Handling, Conveyors, Linear Motion Systems

- Corrosion Resistance

- Available with Corrosion-Resistant Coating

- Static Load Rating

- Available as per model specifications

- Surface Finish

- Ground and Hardened

- Dynamic Load Rating

- Available as per model specifications

- Interchangeability

- Compatible with global standards

- Mounting

- Threaded or Plain Shaft

About Osborn Cam Followers And Load Runners

Osborn Cam Follower, INC., a division of Jason, Inc., evolved from the Osborn Manufacturing Corp. Osborn Manufacturing had grown into the world's largest manufacturer of industrial brushes and foundry machines by the 1940s. The firm was organized and founded in 1887 by a group of investors headed by John Osborn and has evolved as the leader in idler roller & cam follower innovation.

Flanged Crowned

Eccentric Stud Plain Yoke

Flanged Eccentric Stud

V-Groove Concentric Stud

Flanged Yoke V-Groove

Eccentric Stud Heavy Duty Shafts

V-Groove Yoke Plain Concentric Stud

CAM RUNNER- idler - rollers give designers a new way to control linear motion and support the lighter loads that don't require the heavy-duty performance of Osborn's Load Runners idler-rollers. Although they're dimensionally interchangeable with conventional needle bearing cam followers, they provide important performance features no needle-bearing can deliver. No lubrication, no contamination.

Load Runners Styles - Each of the new styles of Osborn Load Runners was originally developed as a "special" to satisfy the requirements of extraordinary loads and severe environments. And each has been proven in thousands of hours of customer applications.

NYLON TREAD - Cost-effective performance in applications requiring a non-metallic outer face.

URETHANE TREAD- Proven in special applications calling for a Wear-Resistant, non-metallic rolling surface. STAINLESS STEEL Use where corrosive or other conditions make standard steel rollers unsuitable.

HIGH-TEMPERATURE - For ovens, galvanizing lines, heat treat furnaces and industrial dryers. Solid Lubricant Now Available Osborn's latest innovation in the Load Runner line is the addition of MicroPoly solid lubricant to the bearing assemblies. It is now available for special Load Runners orders, for hard-to-service or extra-heavy-duty applications.

FLR Flanged - Concentric Stud Style, Inch Sizes

FLRC - Flanged Crown Style - Concentric Stud Style, Inch Sizes

FLRH - High Temp Flanged Style Cam Followers - Inch Sizes

FLRS Stainless Steel Concentric Stud Flanged Cam Followers - Inch Sizes.

FLRSE - Stainless Steel Eccentric Stud Flanged Cam Followers - Inch Sizes

FLRY Flanged Yoke Style - Inch Sizes

HPCE Plain - Eccentric Stud Style - Metric Sizes

CLRY Crowned Yoke Style - Inch Sizes

HPV V-Grooved - Concentric Stud Style - Metric Sizes

HPVE V-Grooved - Eccentric Stud Style - Metric Sizes

HPVA V-Grooved - Yoke Style - Metric Sizes

PLRUE Urethane Tread Eccentric - Inch Sizes

PLRU Urethane Tread Concentric - Inch Sizes

PLRSE Plain - Eccentric Stud Plain Style, Inch Sizes

A Stainless Steel

PLRNE Nylon Tread Load Runners - Eccentric Stud Style

PLRN Nylon Tread Load Runners - Concentric Stud Style

PLRE Plain - Eccentric Stud Style, Inch Sizes

VLR V-Grooved - Concentric Stud Style, Inch Sizes

VLRH V-Grooved Style, Inch Sizes

VLRSE V-Grooved - Eccentric Stud Plain Style

Engineered for Versatile Applications

Osborn Cam Followers and Load Runners suit a variety of industries, including material handling, conveyor systems, and linear motion platforms. Their robust construction and adaptability make them ideal for demanding environments, ensuring smooth performance across a wide range of applications and industries.

Premium Durability and Performance

Constructed from high-grade alloy steel, each cam follower features ground and hardened surfaces and a steel cage (retainer), ensuring exceptional durability. The load runners support high load capacities and maintain precision with their P0 and P6 ratings, while double seals offer protection against contaminants for extended lifespan.

Designed for Harsh Conditions

Operating effectively from -30C to +150C and available with corrosion-resistant coatings, these cam followers are built to handle tough environments. The sealed design keeps lubrication in and contaminants out, making them reliable in both indoor and outdoor settings, regardless of temperature or exposure.

FAQ's of Osborn Cam Followers And Load Runners:

Q: How do I select the correct Osborn Cam Follower or Load Runner for my application?

A: Choosing the right model involves reviewing your application's load requirements (dynamic and static load ratings), operating temperature, speed (up to 6000 RPM depending on size), mounting style (threaded or plain shaft), as well as environmental factors such as exposure to corrosion. Consult the product specification table and select according to bore size, outside diameter, and required type (stud or yoke).Q: What are the benefits of the corrosion-resistant coating available on Osborn Cam Followers?

A: The corrosion-resistant coating protects the cam followers and load runners from rust and deterioration, extending their service life in environments exposed to moisture, chemicals, or outdoor conditions. This feature enhances reliability and reduces maintenance frequency in challenging industrial settings.Q: Where can Osborn Cam Followers and Load Runners be used effectively?

A: These components are suitable for material handling systems, conveyor applications, linear motion assemblies, and a variety of other industrial processes where smooth and reliable movement is essential. Their adaptability and robust construction allow for use in both standard and demanding settings.Q: What maintenance is required for Osborn Cam Followers and Load Runners?

A: Each unit is factory-lubricated for immediate use, but they are also designed for relubrication to ensure optimal long-term performance. Routine inspection and relubrication schedules should be established based on the intensity and environment of your application.Q: When should I opt for the single row configuration offered by Osborn?

A: A single row bearing is ideal for general applications where directional loads are prevalent and space is a consideration. It delivers sufficient load capacity in most material handling and conveyor systems, aligning with standard design needs without occupying excess space.Q: How does the double seal design enhance the performance of these cam followers?

A: The double seals provide superior protection by keeping dust, debris, and contaminants out while retaining lubricant inside. This minimizes maintenance needs and increases operational reliability, particularly in harsh or dirty environments.Q: What makes Osborn Cam Followers compatible with global standards?

A: Osborn's cam followers and load runners are engineered to meet widely recognized international specifications for bearing dimensions and performance, ensuring easy interchangeability and replacement, regardless of your location or the original equipment brand.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cam Followers Category

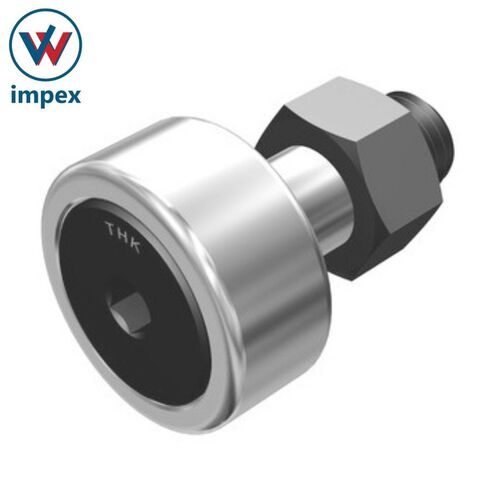

THK Cam Follower Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome steel

Outside Diameter : 32 mm

Thickness : 16 mm

Cage Material : Steel

Smith Cam Follower Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Other, Bearing Steel

Outside Diameter : 35 mm

Thickness : 20 mm

Cage Material : Steel

Carter Bearings USA

Price 500

Minimum Order Quantity : 5 Pieces

Material : Chrome steel

Outside Diameter : 30 mm

Thickness : 9 mm

Cage Material : Steel

JNS Cam Followers

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Quality Bearing Steel

Outside Diameter : 22 mm to 72 mm

Thickness : Varies by model (typically 16 mm to 30 mm)

Cage Material : Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry