Carter Bearings USA

Carter Bearings USA Specification

- Cage Material

- Steel

- Inside Diameter

- 10 mm

- Retainer

- Pressed Steel

- Thickness

- 9 mm

- Lubrication Type

- Grease

- Precision Rating

- ABEC 1

- Bearing Type

- Plain Bearing

- Material

- Chrome steel

- Structure

- Self-Aligning

- Seals Type

- Metal Shielded

- Number Of Rows

- Single

- Bore Size

- 10 mm

- Outside Diameter

- 30 mm

- Limiting Speed

- 16000 RPM

- Load Capacity

- 2500 N

- Finish

- Polished

- Temperature Range

- -20°C to +100°C

- Mounting Type

- Radial

- Dynamic Load Rating

- 2500 N

- Application

- Automotive, Industrial Machinery, Conveyors

- Static Load Rating

- 1200 N

- Packaging Type

- Box

- Product Code

- CB-1030MS

Carter Bearings USA Trade Information

- Minimum Order Quantity

- 5 Pieces

- Supply Ability

- Piece

- Certifications

- Yes

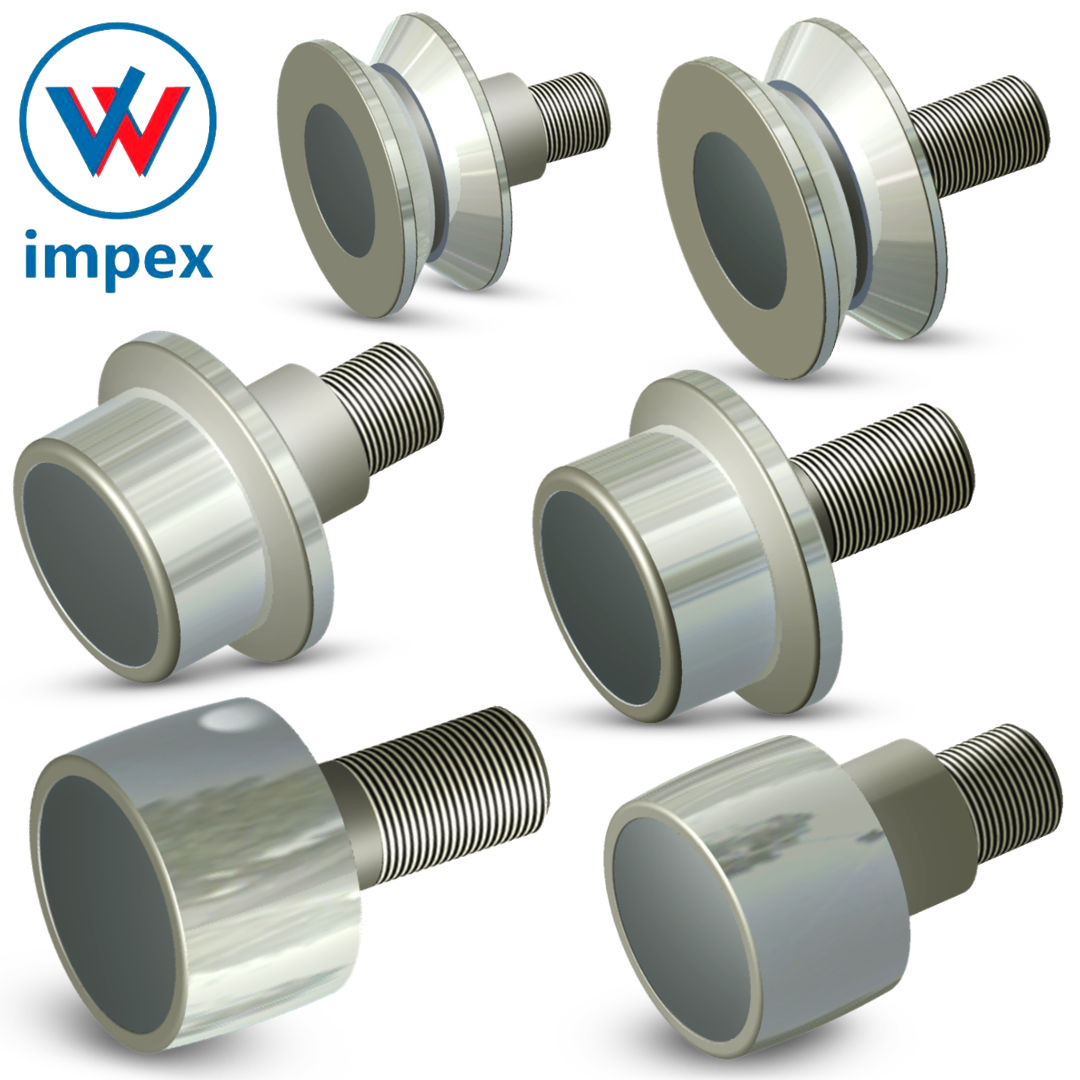

About Carter Bearings USA

Carter Manufacturing specializes in prototyping and manufacturing high precision bearings for both standard and specialized applications in industries such as chemical, food processing and industrial. Carter maintains a large inventory of all of their standard bearings which means they can meet your needs promptly.

Carter Bearing, with headquarters in Grand Haven, Michigan manufactures cam followers designed to meet customer needs all over the world. Carter Bearing also has the ability to produce custom bearings to fill the needs of any size customer from small end user to large OEM outfits.

- Carter Neverlube Cam Followers and Cam Yoke Rollers

Carters advanced design self-lubricating sleeve bearing provides continuous, dependable lubrication for the life of the unit. This advanced design self-lubricating sleeve bearing has a heat-treated steel roller with machined lubrication reservoirs that are pre-filled with specially developed lube mixtures. As the bearing operates, this lubrication penetrates through a porous inner sintered bronze bushing by capillary action providing continuous, dependable lubrication for the life of the bearing.

The permanent lubrication not only eliminates leakage due to over-lubrications, but the plastic lube mixture reverts to its original consistency when the bearing is not in use, Carter Unsealed Crowned Cam Follower preventing any leakage. This is an important advantage in applications such as food processing and pharmaceutical manufacturing. Because there are no internal moving elements, Neverlube bearings offer trouble-free operation in a wide variety of applications, including situations where the equipment is subject to frequent wash downs. Neverlube bearings offer many important benefits to engineers who are developing new equipment for special applications, or redesigning existing equipment to achieve competitive advantages such as lower cost and longer service life.

The simplified design of Neverlube bearings can mean lower cost - The self-lubricating feature also helps reduce maintenance costs and assures adequate lubrication at all times, greatly reducing the possibility of bearing failure and unscheduled downtime. In addition, the Hex Socket, which is an important aid to easy installation and replacement, and which is normally an "extra" is included at no extra cost.

Robust Construction and High Performance

Manufactured from polished chrome steel, the CB-1030MS provides superior strength and corrosion resistance. Its self-aligning capability ensures stable operation even under misalignment, making it ideal for automotive and industrial machinery. Designed for both longevity and reliability, this bearing can handle rigorous load requirements and high-speed applications.

Versatile Application in Industries

Carter Bearings USAs CB-1030MS bearing is widely used in conveyors, automotive components, and diverse industrial machinery. This versatility is enhanced by its single-row, radial mounting structure, making it suitable for various installation configurations. Its temperature tolerance ensures reliable performance in demanding environments.

FAQs of Carter Bearings USA:

Q: How should the CB-1030MS bearing be installed for optimal performance?

A: For optimal results, the CB-1030MS bearing should be mounted radially into compatible housings, ensuring the shaft and housing bore are clean and properly sized. Handle with care to maintain the integrity of the polished chrome steel surface and metal shields.Q: What is the process for lubricating the CB-1030MS bearing?

A: This bearing is pre-lubricated with grease, thanks to its metal-shielded design. Periodic maintenance is recommended, depending on operating conditions, to ensure the grease remains clean and effective for extended bearing life.Q: When should the CB-1030MS bearing be replaced?

A: Replace the CB-1030MS bearing if you notice abnormal noise, increased vibration, or decreased performance. Early replacement prevents damage to machinery and ensures consistent operational efficiency.Q: Where can CB-1030MS bearings be used?

A: The CB-1030MS bearing is suitable for diverse fields, including automotive assemblies, industrial machinery, and conveyor systems. Its temperature range and precision make it adaptable to tough environments and varying application needs.Q: What are the primary benefits of using the CB-1030MS bearing?

A: Users benefit from high durability, excellent load capacity (up to 2500 N), and resistance to high temperatures. The self-aligning structure and ABEC 1 precision provide reliable operation, while the metal shields protect against contaminants, reducing maintenance.Q: How does the self-aligning feature enhance bearing life?

A: The self-aligning structure compensates for shaft misalignment, minimizing stress on the bearing and its housing. This results in smoother operation, less wear and tear, and a longer service life for both the bearing and equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cam Followers Category

Smith Cam Follower Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 5 Pieces

Outside Diameter : 35 mm

Bore Size : 15 mm

Material : Other, Bearing Steel

Thickness : 20 mm

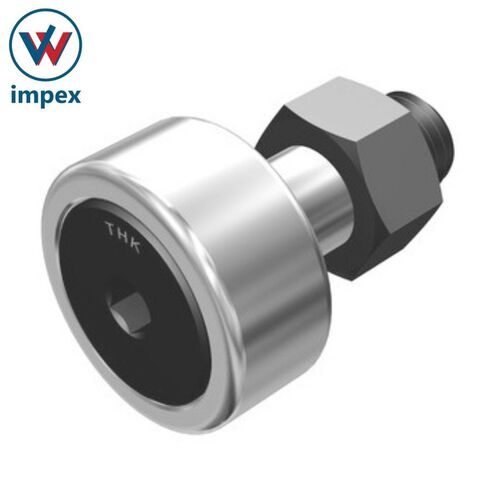

THK Cam Follower Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : 32 mm

Bore Size : 12 mm

Material : Chrome steel

Thickness : 16 mm

RBC Cam Follower Bearing

Price 8500 INR / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : 30 mm

Bore Size : 10 mm

Material : Chrome steel

Thickness : 14 mm

IKO Cam Follower Bearing

Price 560 INR / Piece

Minimum Order Quantity : 2 Pieces

Outside Diameter : 3 to 30 mm

Material : Other

Thickness : 3mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry