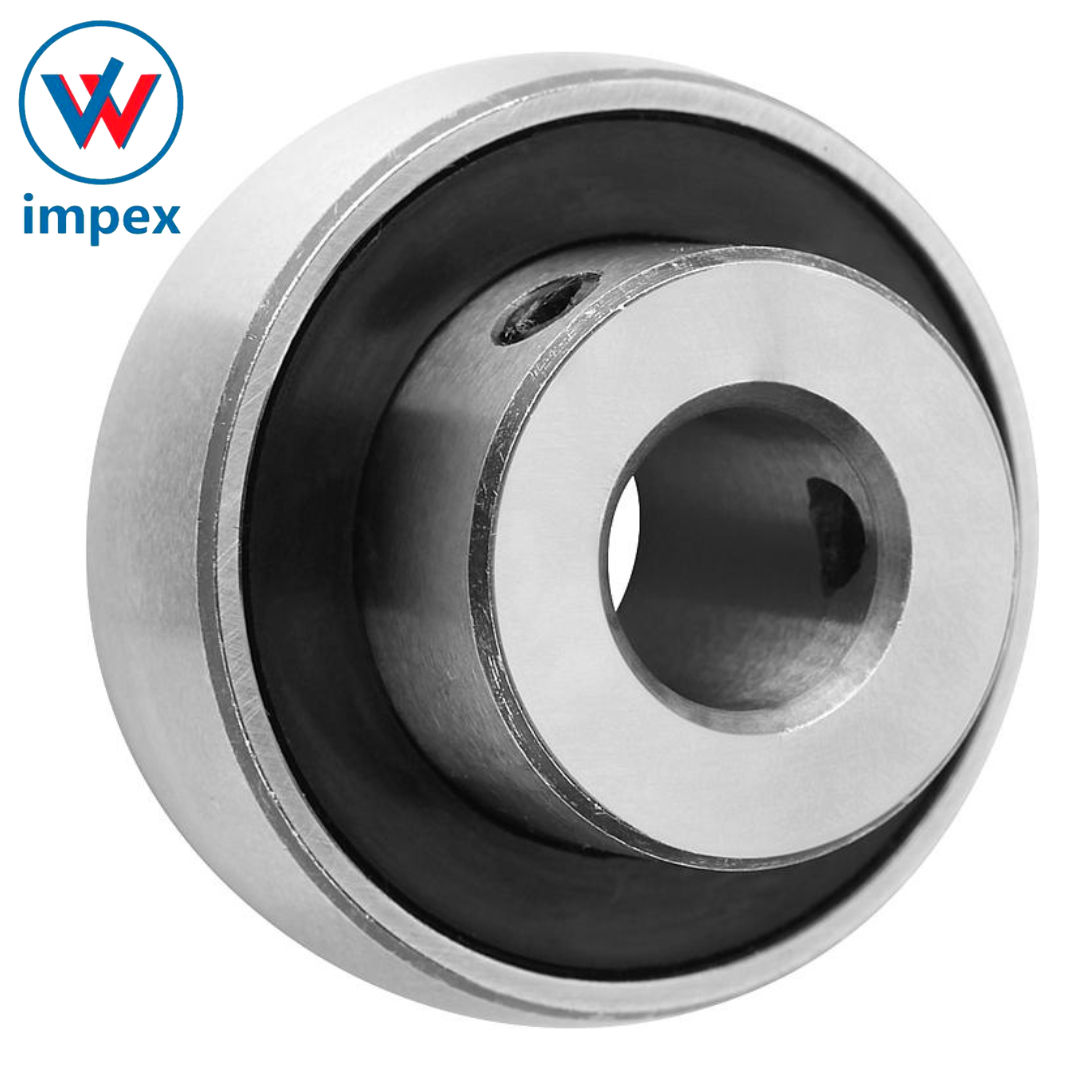

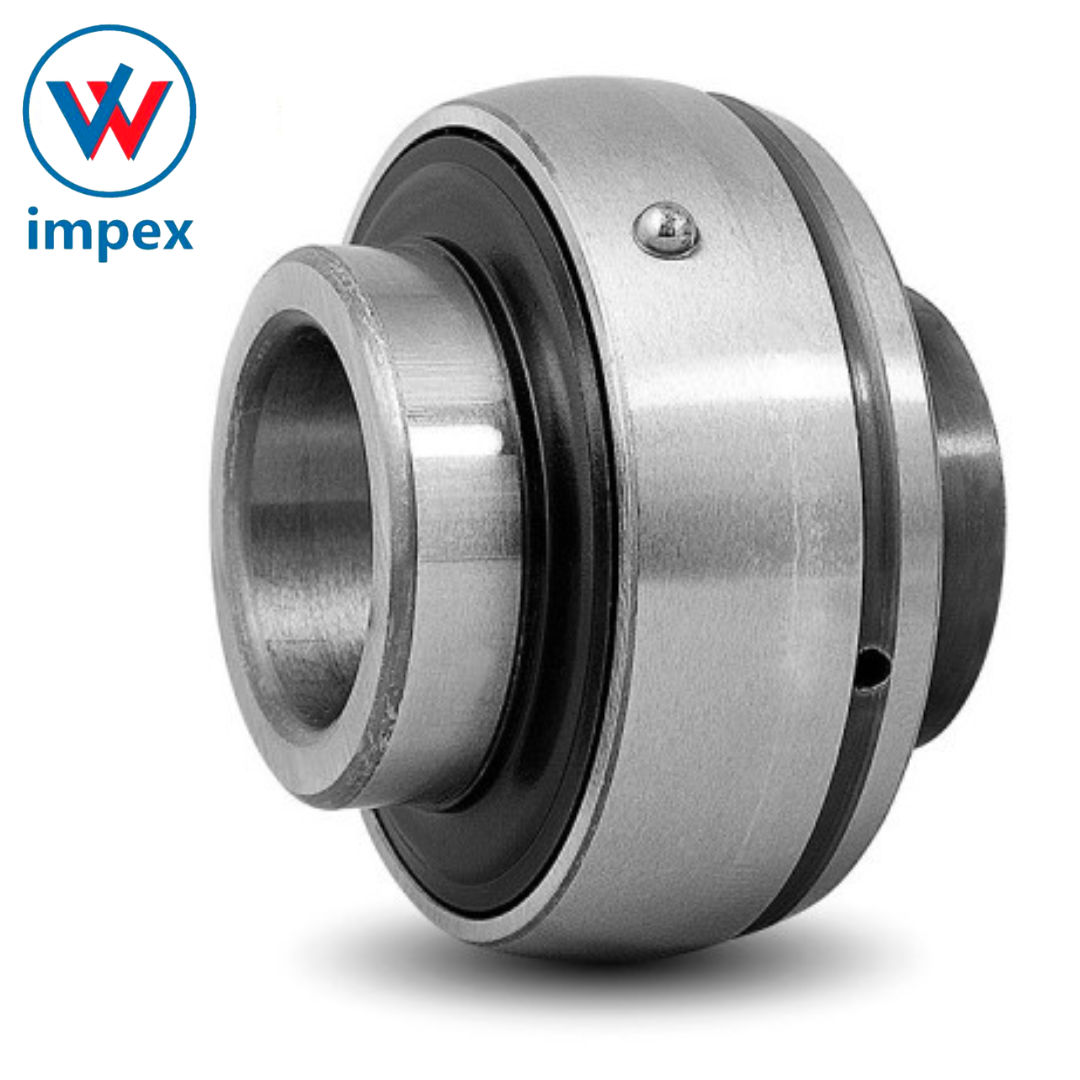

High Temperature Inserts UC Bearing

Price 1000 INR/ Piece

High Temperature Inserts UC Bearing Specification

- Lubrication Type

- High Temperature Grease

- Cage Material

- Steel

- Inside Diameter

- 20 mm

- Thickness

- 14 mm

- Retainer

- Steel

- Precision Rating

- P6

- Bearing Type

- High Temperature Insert Bearing

- Material

- Chrome steel

- Structure

- UC Insert Bearing

- Seals Type

- Double Sealed

- Number Of Rows

- Single

- Bore Size

- 20 mm

- Outside Diameter

- 47 mm

- Limiting Speed

- 6000 RPM

- Load Capacity

- High

- Dynamic Load Rating

- 16.5 kN

- Static Load Rating

- 8.85 kN

- Application

- Food Processing, Textile Machinery, Industrial Furnaces

- Packaging Type

- Box

- Finish Type

- Corrosion Resistant

- Operating Temperature Range

- Up to 180°C

- Mounting Type

- Set Screw

- ISO Certification

- ISO 9001:2015

High Temperature Inserts UC Bearing Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- Days

- Certifications

- Yes

About High Temperature Inserts UC Bearing

High Temperature Inserts UC Bearing

High Temperature Inserts (UC Bearing) are specifically designed to operate in temperatures up to 250*C 280*C. The combination of heat stabilization, greater internal clearance, advanced Viton seals, specially selected high temperature lubricants, what make these units & inserts the perfect solution that can endure operating at elevated temperatures. Available in 250*C and 280*C.

Product Flyer- C4 Internal Clearance

- Viton Seals

- Steel Cages

- Fixed and Float (expansion)

- All Housing Styles Available

| UC 204 BHTS 2RS VT 250*-280* |

| UC 205 BHTS 2RS VT 250*-280* |

| UC 206 BHTS 2RS VT 250*-280* |

| UC 207 BHTS 2RS VT 250*-280* |

| UC 208 BHTS 2RS VT 250*-280* |

| UC 209 BHTS 2RS VT 250*-280* |

| High Temp Flange units UCF 204 BHTS 2RS VT 250*-280* |

| UCF 205 BHTS 2RS VT 250*-280* |

| UCF 206 BHTS 2RS VT 250*-280* |

| UCF 207 BHTS 2RS VT 250*-280* |

| UCF 208 BHTS 2RS VT 250*-280* |

| UCF 209 BHTS 2RS VT 250*-280* High Temp plummer Block |

| UCP 204 BHTS 2RS VT 250*-280* |

| UCP 205 BHTS 2RS VT 250*-280* |

| UCP 206 BHTS 2RS VT 250*-280* |

| UCP 207 BHTS 2RS VT 250*-280* |

| UCP 208 BHTS 2RS VT 250*-280* |

| UCP 209 BHTS 2RS VT 250*-280* |

Exceptional Heat Resistance

Designed to operate in temperatures up to 180C, this UC Insert Bearing is suitable for high-heat industrial applications such as furnaces and textile machinery. Its advanced high-temperature grease ensures smooth operation and longevity, even in continuous, demanding processes.

Reliability for Critical Industries

Certified under ISO 9001:2015, the bearing provides peace of mind to industries demanding stringent quality standards. Whether used in food processing or heavy machinery, its corrosion-resistant finish and double-sealed structure keep contaminants out, maintaining optimal performance.

Precision and High Load Capacity

The bearing delivers a dynamic load rating of 16.5 kN and a static rating of 8.85 kN, supporting both rotational precision and high operational loads. Featuring a P6 precision rating, its chrome steel construction and steel retainer guarantee excellent performance and durability.

FAQs of High Temperature Inserts UC Bearing:

Q: How is the High Temperature UC Insert Bearing installed in machinery?

A: The bearing features a set screw mounting system, allowing for straightforward installation onto shafts. Its UC insert structure enables secure placement while minimizing movement during high-speed operation.Q: What advantages does the double sealed design provide in industrial environments?

A: The double seal protects the interior components from contaminants, moisture, and high-temperature exposure, substantially extending the bearings lifespan and maintaining performance across demanding applications.Q: When should this bearing be used instead of standard bearings?

A: This bearing is ideal when your application involves high temperatures, corrosive environments, or requires high load capacity and precision, such as in food processing equipment, textile machinery, and industrial furnaces.Q: Where is this bearing commonly utilized?

A: It is frequently used in sectors that require reliable operation under harsh conditions, including food processing plants, textile factories, and industrial furnace settings, both in Italy and internationally.Q: What is the process for maintaining this bearing?

A: Maintenance involves inspecting the seals and cleaning the exterior. Thanks to the high temperature grease lubrication and corrosion-resistant finish, routine service needs are minimalperiodically check for wear or contamination to ensure long-term performance.Q: How does ISO 9001:2015 certification benefit users?

A: The ISO 9001:2015 certification provides assurance of consistent quality, robust manufacturing processes, and reliability, giving distributors, exporters, importers, suppliers, and traders confidence in the product.Q: What usage benefit does the high dynamic load rating offer?

A: With a dynamic load rating of 16.5 kN, the bearing supports heavy rotational loads, making it an effective choice for machinery subjected to intense operational demandsimproving equipment reliability and minimizing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Temperature Bearing Category

BRL High Temperature Bearing

Price 6500 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Chrome steel

Thickness : 9 mm

SNR High Temperature Bearings

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Chromium Steel

Thickness : 17 mm

BECO High Temperature Bearing

Price 1250 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Stainless Steel

Thickness : MAX

Usage : Industrial

Color : silver

SKF High Temperature Bearing

Price 4500 INR / Piece

Minimum Order Quantity : 2 Pieces

Usage : Industrial

Color : Black

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry