BRL High Temperature Bearing

Price 6500 INR/ Piece

BRL High Temperature Bearing Specification

- Thickness

- 9 mm

- Cage Material

- Steel / Nylon / Brass

- Precision Rating

- P0 / P6

- Inside Diameter

- 10 mm

- Lubrication Type

- High Temperature Lubrication

- Retainer

- Steel / Brass

- Bearing Type

- High Temperature Bearing

- Material

- Chrome steel

- Structure

- Deep Groove

- Seals Type

- Open / ZZ / 2RS

- Number Of Rows

- Single Row

- Bore Size

- 10 mm

- Outside Diameter

- 30 mm

- Limiting Speed

- Up to 18000 rpm (depending on type)

- Load Capacity

- High

- Surface Finish

- Polished

- Operating Temperature Range

- -40°C to 300°C

- Corrosion Resistance

- Yes

- Vibration Level

- Low

- Application

- High Temperature Machinery

- Noise

- Low

BRL High Temperature Bearing Trade Information

- Minimum Order Quantity

- 10 Pieces

- Delivery Time

- Days

- Certifications

- Yes

About BRL High Temperature Bearing

Considering our rich experience and knowledge, our firm is noted amongst the leading manufacturers and suppliers of high quality BRL High Temperature Bearing. These bearings are made at our fully incorporated manufacturing unit by making use of matchless quality materials and sophisticated technologies. Our entire range of BRL High Temperature Bearing is suitably utilized in roller chains, industrial fans, packaging machinery, steel and ceramic works for reducing the friction between two moving parts.

Features:

- Can withstand heavy radial load

- Rust proof finish

- High temperature endurance

Further Details:

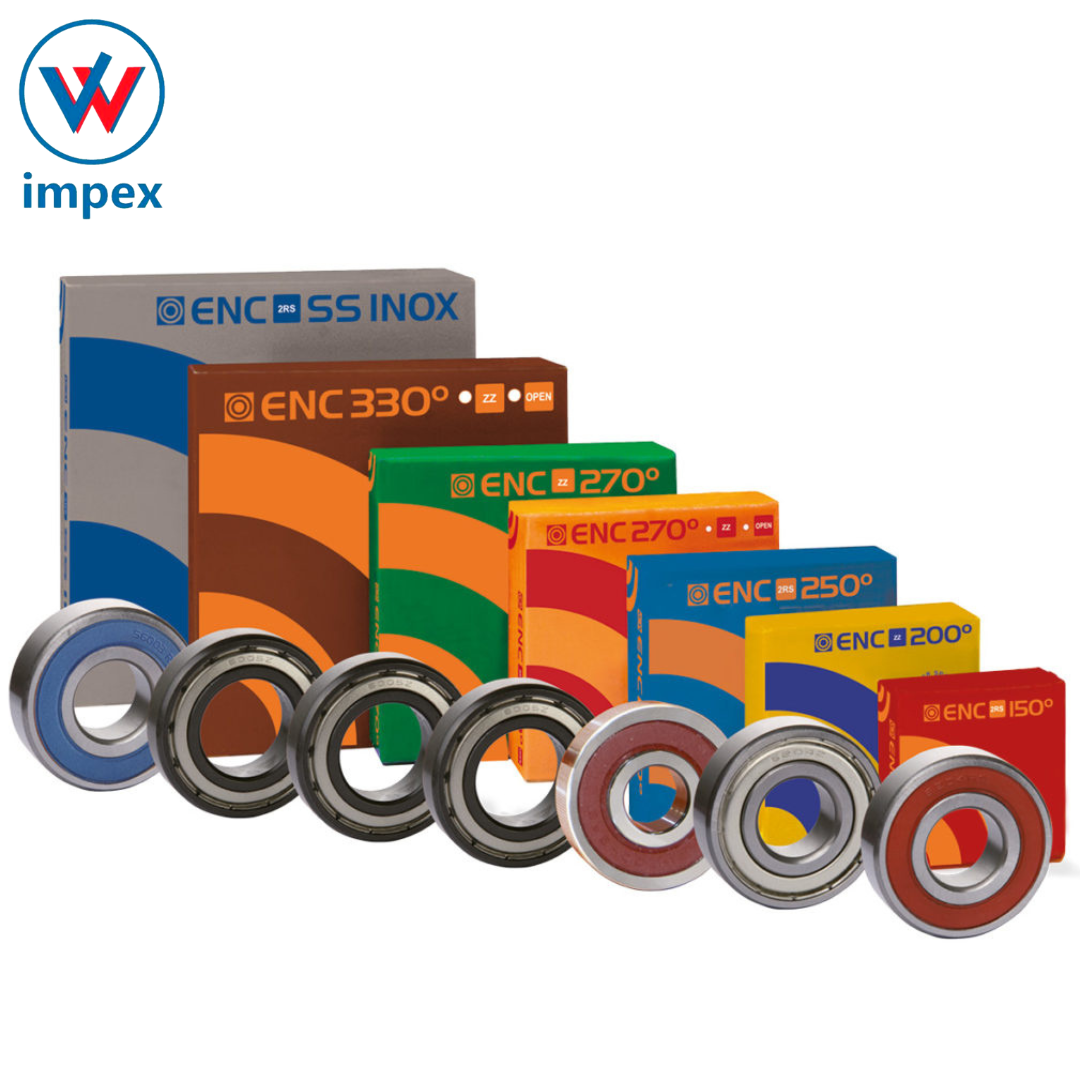

BRL High Temperature Bearing is a distributor based in the Barcelona Region, we specialize in rotational solutions for high temperature applications predominantly in the bearing series of 6000, 6200 and 6300 which can handle temperatures from 150 degree C to 330 degree C. One color for each temperature, as easy as that BRL has designed boxes in different colors for each product range according to their respective working temperatures, making it easier to identify and describe them in your warehouse.Technical Characteristics:

- AISI 52100 Steel

- C4 radial clearance

- Grease from -25 degree C to 200 degree C

- ZZ shields

- Industrial fans

- Packaging machinery

- Ceramic industry

- Roller chains

- Steel production

Excellent Performance in High Temperature Environments

The BRL High Temperature Bearing is ideal for machinery exposed to extreme heat. With a wide temperature range of -40C to 300C and high corrosion resistance, it withstands harsh conditions while maintaining consistent operation. Polished surface and specialized lubrication further extend its lifespan.

Precision Engineering for Low Noise and Vibration

Featuring a deep groove, single row structure, the bearing offers smooth, quiet, and low-vibration operation. Precision ratings of P0 and P6 ensure consistent, reliable motion, making it suitable for noise-sensitive applications in industries like manufacturing and automation.

Versatile Options for Multiple Applications

This bearing accommodates various requirements with options such as open, ZZ, or 2RS seals, and cage materials like steel, nylon, or brass. Its high load capacity and limiting speed up to 18000 rpm (depending on type) make it versatile for a wide range of high temperature equipment.

FAQs of BRL High Temperature Bearing:

Q: How does the BRL High Temperature Bearing ensure reliable operation in extreme heat?

A: The BRL High Temperature Bearing is specifically designed to operate between -40C and 300C, using chrome steel construction and high temperature lubrication to maintain durability and performance even in severe thermal environments.Q: What industrial applications are best suited for this bearing?

A: This bearing excels in high temperature machinery, such as ovens, kilns, and furnaces in sectors like automotive, metallurgy, and manufacturing, where both heat resistance and low vibration are vital.Q: When should I select between Open, ZZ, or 2RS seals for my application?

A: Seal type selection depends on environmental exposure. Open bearings suit clean, dry settings; ZZ (metal shields) offer moderate protection against dust; 2RS (rubber seals) provide superior sealing for environments with higher contamination risk.Q: Where is this bearing commonly supplied or exported from?

A: BRL High Temperature Bearings are frequently supplied, exported, and distributed from Belgium to industrial clients worldwide, ensuring global availability and support.Q: What is the process for installing this bearing in high temperature machinery?

A: Installation involves cleaning the housing, ensuring correct alignment, and using proper lubrication. Its essential to avoid forcing the bearing during fitting to preserve its internal structure and maximize lifespan.Q: How does the bearings structure benefit its performance?

A: Its deep groove, single row structure, combined with high precision ratings, results in high load carrying capability, stable rotation at high speeds, and reduced noise and vibration, making it effective in demanding machines.Q: What are the main advantages of choosing this corrosion-resistant bearing?

A: Benefits include prolonged service life even in harsh or corrosive environments, reduced maintenance intervals, and reliable operationattributes crucial for maximizing machinery uptime in industrial settings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in High Temperature Bearing Category

SNR High Temperature Bearings

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, High Chromium Steel

Thickness : 17 mm

High Temperature Inserts UC Bearing

Price 1000 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Chrome steel

Thickness : 14 mm

BECO High Temperature Bearing

Price 1250 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Stainless Steel

Color : silver

Usage : Industrial

Thickness : MAX

SKF High Temperature Bearing

Price 4500 INR / Piece

Minimum Order Quantity : 2 Pieces

Color : Black

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry