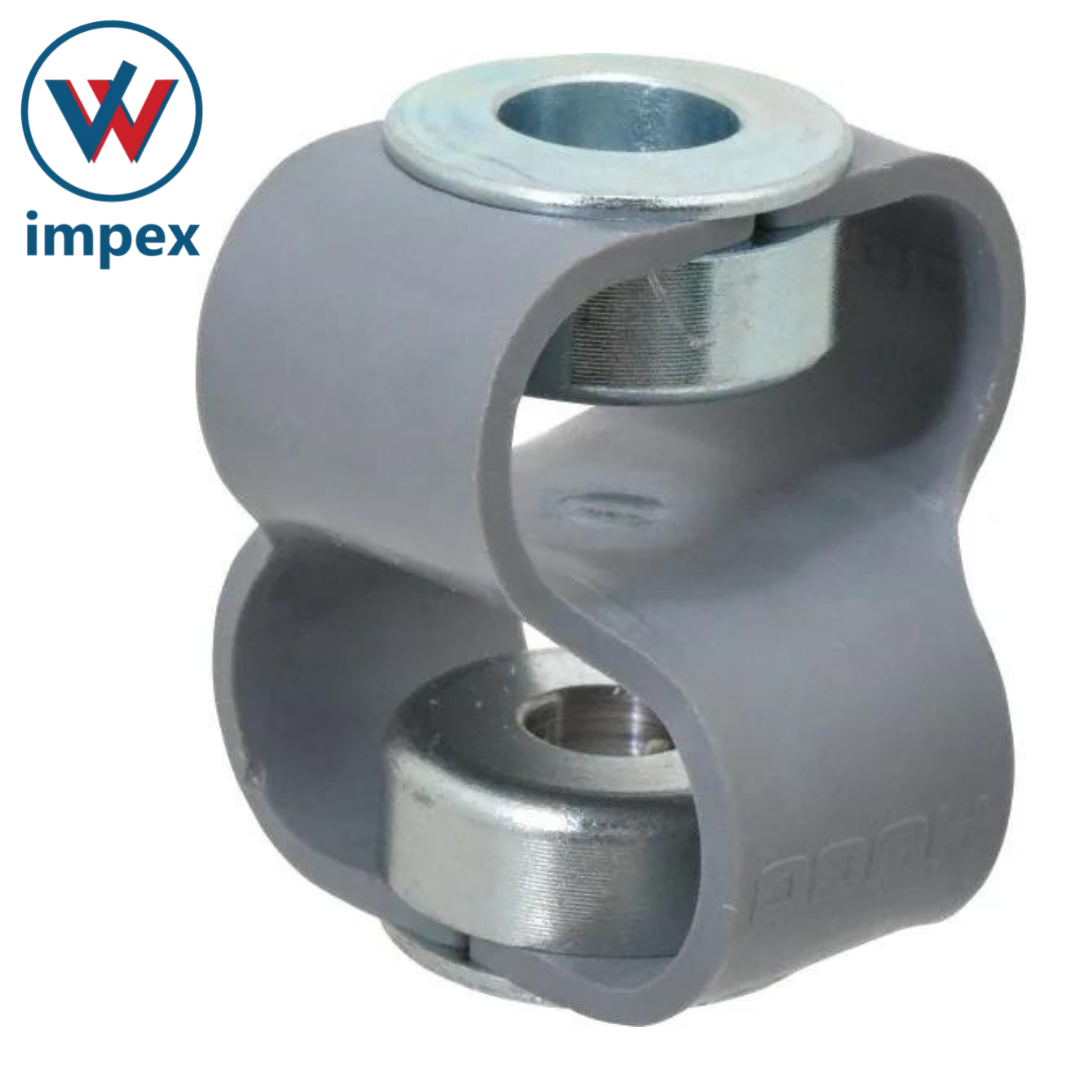

Double Loop Flex P Coupling Huco

Price 3500 INR/ Piece

Double Loop Flex P Coupling Huco Specification

- Lubrication Type

- Maintenance Free / Dry

- Cage Material

- Polyamide (Loop)

- Precision Rating

- High Precision

- Thickness

- Standard Profile (Approximately 14 mm)

- Inside Diameter

- Customizable as per bore size

- Material

- Aluminum Alloy & Polyamide Loop

- Structure

- Double Loop Flex Coupling

- Number Of Rows

- Single

- Bore Size

- 6 mm - 12 mm

- Outside Diameter

- 28 mm

- Limiting Speed

- up to 10,000 rpm

- Load Capacity

- Medium Torque Transmission

- Connection Method

- Clamp or set screw

- Temperature Range

- -40°C to +80°C

- Weight

- Approx. 14 grams

- Recommended Use

- Encoder, instrumentation, and light-duty application

- Coupling Type

- Flexible Shaft Coupling

- Misalignment Compensation

- Radial, Angular, and Axial

- Standard/Compliance

- RoHS Compliant

- Finish

- Anodized

About Double Loop Flex P Coupling Huco

The double loop coupling uses a moulded plastic element permanently swaged to steel or stainless steel hubs to give a compact design. It forms an effective two-stage coupling with exceptional flexibility in all three modes. Ideal for transmitting rotation in small drives, this type of coupling works without any friction, wear or noise, although its low torsional stiffness makes it less suitable for high precision positioning applications.

Exceptional flexibility in all three directions: radial, angular and axial.

Product Features

Speeds: Up to 3000 rpm

Peak Torque Largest Size lbs.-in (Nm): 159 (18)

Standard Bores in. (mm): 1/8" -5/8" (3 to 16)

Temperature: -40* to +210*F , (-40* to +100*C)

Electrically Isolating: Yes

Connection: Set Screw

Exceptional flexibility

Compact design

Outstanding resistance to acids, alkilis, solvents, oils, greases, ozone

Tough double-loop elastomeric element made from HYTREL

Zinc plated steel hubs

Precision and Flexibility for Demanding Applications

With its high-precision engineering and double loop flex design, this coupling is ideal for sensitive equipment like encoders and instrumentation systems. The ability to accommodate shaft misalignments while transmitting medium torque ensures stable performance in light-duty industrial settings. This reliability reduces the risk of system downtime and increases operational efficiency across varied applications.

Engineered for Durability and Safety

Crafted from premium anodized aluminum alloy and featuring a robust polyamide loop, the Double Loop Flex P Coupling Huco offers prolonged service life and dependable corrosion resistance. Its RoHS compliance aligns with international safety standards, while the maintenance-free, dry operation simplifies long-term use for businesses seeking minimal intervention and robust safety standards.

FAQs of Double Loop Flex P Coupling Huco:

Q: How does the double loop flex structure benefit my application?

A: The double loop flex structure allows the coupling to effectively compensate for radial, angular, and axial shaft misalignments. This results in improved alignment tolerance, vibration reduction, and reliable torque transmission, especially important in applications such as encoders and instrumentation.Q: What bore sizes can the Double Loop Flex P Coupling accommodate?

A: This coupling model supports bore sizes from 6 mm to 12 mm as standard, and the inside diameter can be customized within this range to suit different shaft requirements. This flexibility makes it suitable for various equipment and installations.Q: When should I use a flexible shaft coupling like this?

A: You should use the Double Loop Flex P Coupling Huco in light-duty scenarios where precision is essential, shaft misalignment exists, and minimal maintenance is desired. Its particularly recommended for encoders and instrumentation applications prone to minor alignment errors.Q: Where is this coupling commonly used?

A: Common applications include control instrumentation, feedback systems, sensors, and encoder assemblies in industries like automation, robotics, and laboratory instrumentation, especially within environments requiring compliance and precise movement.Q: What is the connection method for installation?

A: Installation is straightforward, utilizing either a clamp or set screw as the connection method. This ensures a secure fit around the shaft and enables easy adjustments or removal during maintenance or upgrades.Q: What are the main benefits of choosing this RoHS-compliant coupling?

A: Selecting this RoHS-compliant coupling provides assurance of environmental safety, high precision, low maintenance, and adaptability for use in temperature-extreme or sensitive applications, such as those found in the United Kingdoms advanced industries.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Couplings & Gears Category

Renold Clutch And Couplings

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Clutch Coupling

Material : Other, Alloy Steel

Precision Rating : ISO Standard

Retainer : Metal

TSCHAN / RINGFEDER Couplings

Price 15000 INR / Piece

Minimum Order Quantity : 2 Pieces

Structure : Flexible jaw coupling

Material : Other, Steel / Cast Iron / Polyamide (spider)

Precision Rating : ISO G6.3

Retainer : Integrated spider retainer

TB Woods Jaw Couplings

Price 5000

Minimum Order Quantity : 1 Piece

Structure : Jaw Coupling

Material : Other, Cast Iron or Steel (Coupling); Nitrile Rubber (Spider)

Precision Rating : Standard Industrial

STS Coupling GMBH

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Structure : Flexible Coupling

Material : Other, Metal

Precision Rating : High Precision

Retainer : Builtin Retainer

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry