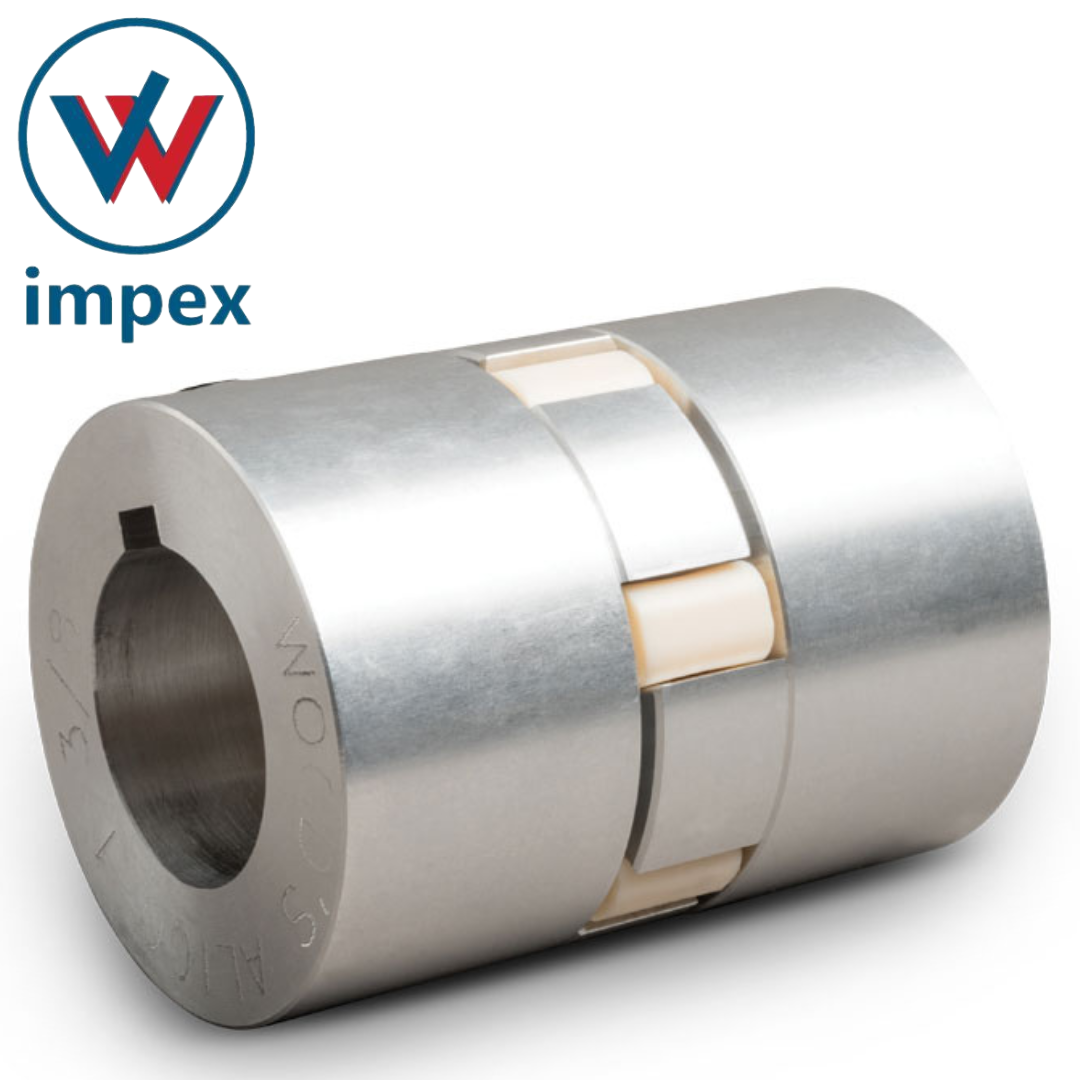

TB Woods Jaw Couplings

TB Woods Jaw Couplings Specification

- Precision Rating

- Standard Industrial

- Inside Diameter

- Same as Bore Size

- Lubrication Type

- No lubrication required (maintenance-free)

- Thickness

- Depends on model, ranges from 22 mm to 98 mm

- Material

- Cast Iron or Steel (Coupling); Nitrile Rubber (Spider)

- Structure

- Jaw Coupling

- Seals Type

- Standard (no seals, open design)

- Number Of Rows

- Single

- Bore Size

- 10 mm to 100 mm (varies by model)

- Outside Diameter

- 22 mm to 250 mm (varies by model)

- Limiting Speed

- Up to 12,000 RPM (varies by size and type)

- Load Capacity

- Up to 2300 Nm (depends on coupling size)

- Installation

- Easy installation and alignment

- Standards

- Meets industry standards (AGMA, ISO)

- Type

- Flexible Jaw Coupling

- Spider Material

- Nitrile Rubber (standard), also available in Polyurethane or Bronze

- Temperature Range

- -40°C to +100°C (standard spider)

- Misalignment Capability

- Axial, Angular, and Parallel misalignment

- Application

- Pumps, Compressors, Conveyors, Fans, Mixers, and General Power Transmission

About TB Woods Jaw Couplings

TB Woods Jaw Couplings

TB Wood is an industry leading designer and manufacturer of mechanical power transmission equipment for industrial applications. Our mechanical product lines include: synchronous, v-belt, and belted variable speed drives; grid, disk, jaw, gear and elastomeric coupling products; sheaves and bushings, sprockets and clutches. Registered trademarks include Sure-Flex , Dura-Flex Form-Flex , G-Flex and Sure-Grip Bushings.

Couplings

Sheaves & V-Belts

|

Versatile Alignment and High Performance

TB Woods Flexible Jaw Couplings are engineered to support axial, angular, and parallel misalignment, ensuring smooth torque transmission even when exact alignment is challenging. Their design minimizes vibration and absorbs shock loads, extending equipment life and reducing downtime in demanding industrial environments.

Durable Construction and Wide Compatibility

Manufactured from robust cast iron or steel, these couplings are equipped with high-quality spiders in nitrile rubber as standard, with options in polyurethane or bronze for varied applications. Each coupling meets important industry standards such as AGMA and ISO, assuring compatibility and safety across industries in India and worldwide.

Simple Installation and Maintenance-Free Operation

TB Woods Jaw Couplings feature an open, single-row structure that enables straightforward assembly and alignment. Designed with a maintenance-free philosophy, there is no need for lubrication, which simplifies use and lowers ongoing maintenance costs for end users.

FAQs of TB Woods Jaw Couplings:

Q: How do TB Woods Flexible Jaw Couplings handle misalignment?

A: These jaw couplings are designed to accommodate axial, angular, and parallel misalignments, making them ideal for applications where perfect shaft alignment is difficult to achieve, thereby minimizing wear and vibration.Q: What spider material options are available, and how do they impact performance?

A: Standard couplings use a nitrile rubber spider, providing good damping and flexibility. For specialized needs, spiders are also available in polyurethane or bronze, allowing users to tailor performance to specific durability or chemical resistance requirements.Q: When should TB Woods Jaw Couplings be selected for use?

A: They are best suited for power transmission systems in pumps, compressors, conveyors, fans, and mixers, especially when easy installation, precise alignment, and vibration damping are important operational factors.Q: What is the installation process for these couplings?

A: With their open, single-row structure, installation is straightforward: align the coupling halves and insert the spider between them before securing everything to the shafts. No lubrication or complex tools are required.Q: Where can TB Woods Jaw Couplings be sourced in India?

A: These couplings are available through authorized distributors, exporters, importers, suppliers, and traders across India, ensuring rapid product availability and service.Q: What are the benefits of using maintenance-free, open-design couplings?

A: The open, no-seal design eliminates the need for lubrication and frequent maintenance, reducing downtime and operational costs, while enhancing overall reliability in duty cycles.Q: What standards do these couplings meet, and why is this important?

A: They are manufactured to AGMA and ISO standards, ensuring interchangeability, safety, and compatibility with global industrial systems, which is critical for seamless integration and operational consistency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Couplings & Gears Category

Neugart Planetary Gearbox

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Load Capacity : Up to 3000 Nm depending on model

Structure : Planetary Gearbox

Limiting Speed : Up to 6000 rpm

Inside Diameter : Depends on shaft size

Renold Clutch And Couplings

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Load Capacity : Up to 250 kNm

Structure : Clutch Coupling

Limiting Speed : 4000 rpm

Inside Diameter : According to bore size

Ruland Shaft Collars And Couplings

Price 5000 INR / Piece

Minimum Order Quantity : 5 Pieces

Load Capacity : Application dependent

Structure : Onepiece and twopiece design options

Limiting Speed : Up to 10,000 RPM depending on style

Inside Diameter : 1/4 inch to 6 inch

RU-STEEL Flexible Couplings

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Load Capacity : High

Structure : Flexible Coupling

Limiting Speed : Up to 5000 RPM

Inside Diameter : As per shaft size

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry