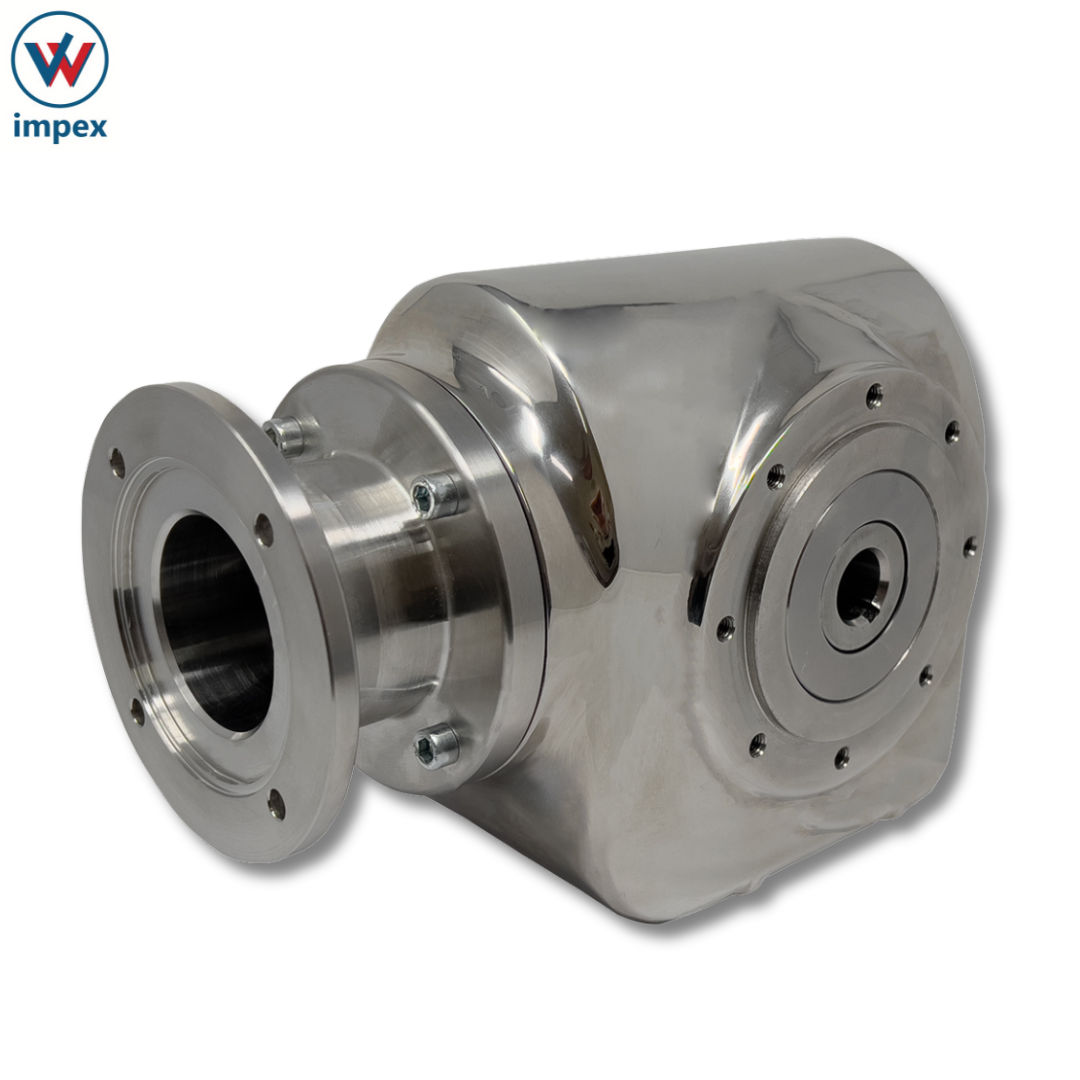

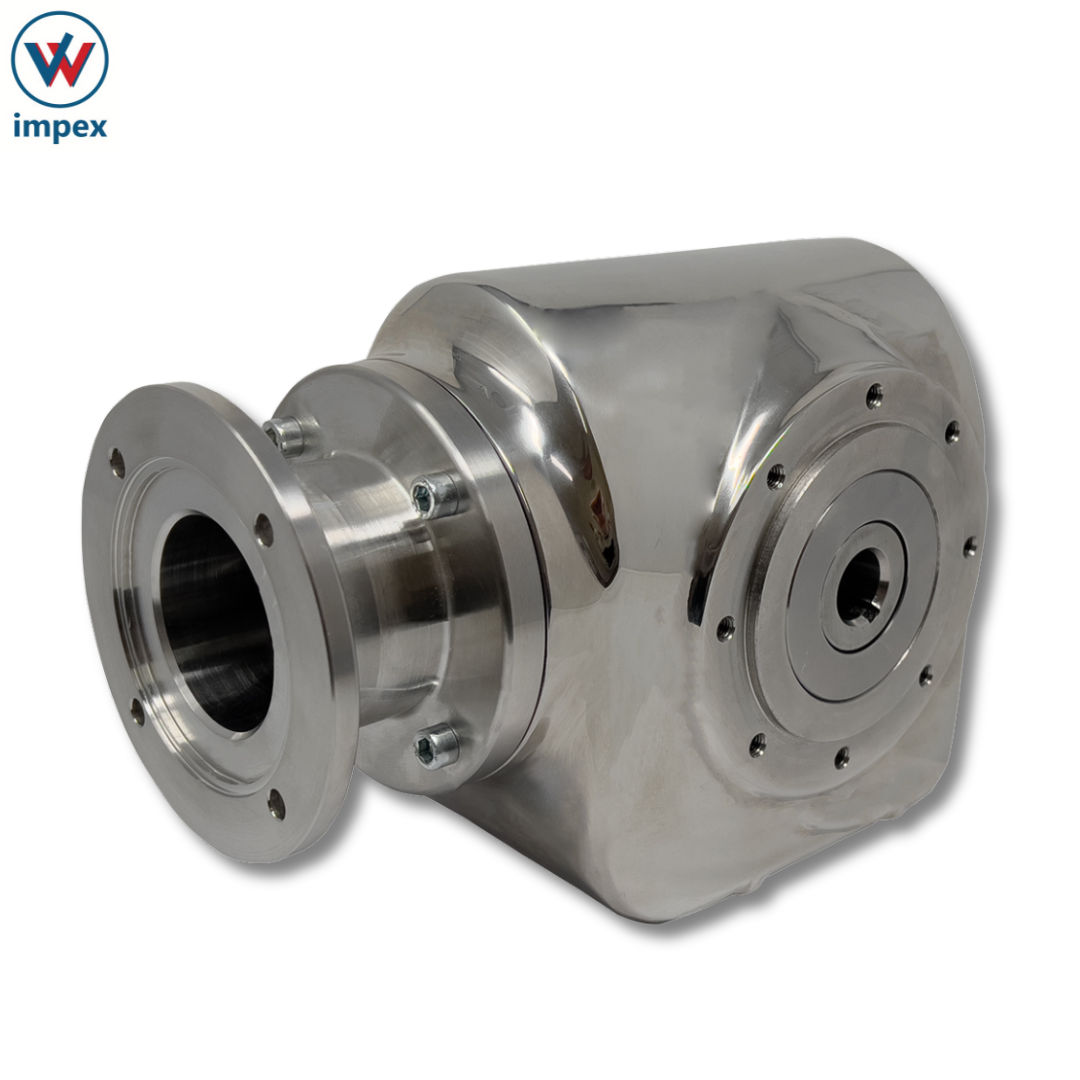

CMR Riduttori Gearbox & Gear Reducers

Price 50000.00 INR/ Piece

CMR Riduttori Gearbox & Gear Reducers Specification

- Cage Material

- Steel

- Lubrication Type

- Oil Splash

- Retainer

- Metal

- Precision Rating

- ISO 1328

- Thickness

- Robust Housing

- Inside Diameter

- Customizable

- Bearing Type

- Ball and Roller Bearings

- Material

- Cast Iron / Aluminum

- Structure

- Helical

- Seals Type

- Double Lip Seal

- Number Of Rows

- Single

- Bore Size

- Customizable

- Outside Diameter

- Varies by Model

- Limiting Speed

- Up to 3600 rpm

- Load Capacity

- High Torque

- Mounting Type

- Foot Mounted / Flange Mounted

- Protection Class

- IP55

- Input Power

- Up to 50 kW

- Output Shaft Type

- Solid and Hollow

- Ambient Temperature

- -10°C to +60°C

- Finish

- Corrosion Resistant Paint

- Gear Ratio

- 5:1 to 70:1

- Application

- Conveyors, Mixers, Industrial Machinery

- Noise Level

- Low Noise Operation

About CMR Riduttori Gearbox & Gear Reducers

CMR Riduttori., has been designing, manufacturing and distributing its range of power transmission products on a global network for over 20 years, mainly consisting of: worm gear reducers and gearmotors, stainless steel reducers, reducers designed to the specific needs of our customers, helical pre-stages, variators, three-phase asynchronous motors and various accessories including flanges, connection kits, shafts, etc., etc., capable of meeting and satisfying the most complex requests arising from various industrial sectors. The production is carried out at factories located in Italy and abroad. Technical and dimensional characteristics, top-level performance guarantee interchangeability with the products of the main players in the sector. CMR Riduttori, a precision mechanical industry in Emilia Romagna, proposes itself as a reliable Partner to support the growth of its customers, important OEMs in the sector who increasingly require "just in time" supplies, speed, punctuality and reliability and retailers with needs for wide availability and competitive prices.

RANGE OF POWER TRANSMISSIONS

1) WORM GEAR REDUCERS - They design and manufacture industrial gear units for a wide variety of applications and industry segments. Ideal for heavy-duty applications and always with a special focus on competitive prices. Our range includes the main sizes normally required.

2) STAINLESS STEEL REDUCERS - New range of stainless-steel gear units with mirror-polished housings, ideal for applications in the pharmaceutical, milling, food & beverage industries. The housing surfaces are designed to prevent powdery or fluid products from accumulating and pooling.

3) REDUCERS FOR TYRE CHANGERS - Reducers mainly designed for use in tyre changing machines. Output shafts can be provided with various different tapers or clearance angles.

4) REDUCERS FOR ROLLER DOORS - Aluminium reducer designed for roller doors. Pre-engineered for coupling to an encoder. Stock managed items and series. Reduction ratios: from 10/1 to 40/1, Applicable motors from PAM 71 to PAM 8025 mm. diameter hollow output shaft.

5) HELICAL REDUCERS - They manufacture series of low-backlash helical reducers with ratios from 3 to 512 and 4.5 Nm. to 800 Nm. torque values. They can be supplied complete with DC motor on request.

6) HELICAL-WORM GEAR UNITS - PR Series Helical- Worm Gear Units - Sizes: 4 sizes, Helical-worm gear unit with motor coupling: from PAM 63 to PAM 90, Pre-engineered for motor coupling: flange B5, Reduction ratios: from 2.43/1 to 3/1

7) SPEED VARIATORS - Mechanical stepless speed variator with motor power from size 63 to size 90.Sizes: 6 sizes, Motor flange built into casting, Input power (1,400 rpm): from 0.18 kW to 4 kW

8) ASYNCHRONOUS ELECTRIC MOTORS - Three-phase, single-phase asynchronous motors, Self-braking motors

9) COMBINED WORM GEARBOXES

Advanced Design for Industrial Applications

CMR Riduttori Gearbox & Gear Reducers leverage helical gear design for smooth, efficient power transmission, making them ideal for heavy-duty tasks in conveyors, mixers, and various industrial machines. The robust housing, customizable options, and corrosion-resistant paint provide enduring durability and operational flexibility, even under harsh conditions.

Performance and Reliability

With a high torque output, precise engineering according to ISO 1328 standards, and reliable ball and roller bearings, the gear reducers consistently deliver optimal performance. The low-noise operation and double lip seal protection further ensure trouble-free usage, minimizing downtime and maintenance requirements for users.

Tailored Solutions from Italy

Offering both solid and hollow shafts with variable bore sizes, these reducers meet diverse application needs. Whether distributed, exported, imported, or supplied globally, every unit is crafted to withstand ambient temperatures from -10C to +60C, reflecting the commitment to quality, adaptability, and longevity expected from Italian manufacturing.

FAQ's of CMR Riduttori Gearbox & Gear Reducers:

Q: How do I choose between foot mounted and flange mounted gearbox configurations?

A: Selecting the right mounting type depends on your machinery layout and installation requirements. Foot mounted gearboxes are ideal for base-level, horizontal installations, while flange mounted options provide robust attachment directly to vertical surfaces or components.Q: What are the advantages of the IP55 protection class for industrial environments?

A: IP55 protection ensures that the gearboxes are safeguarded against dust intrusion and water jets from any direction, making them suitable for use in challenging industrial settings where exposure to moisture or particulates can occur.Q: When should I opt for a solid output shaft versus a hollow output shaft?

A: Solid output shafts are recommended for direct torque transmission to mechanical components, whereas hollow shafts are preferable when coupling with drive shafts or for space-efficient installations in conveyor and mixer systems.Q: Where can these gear reducers be used effectively?

A: CMR Riduttori gearboxes are versatile and suited for integration into conveyors, mixers, and a broad range of industrial machinery. Their corrosion-resistant finish and customizable features make them adaptable to varied manufacturing, processing, and material handling industries.Q: What is the process for customizing bore size or output shaft specifications?

A: Customization can be requested through authorized distributors, exporters, or suppliers. Provide your specific application requirements-such as bore diameter, output shaft type, and other dimensions-to receive a tailored solution that matches your operational needs.Q: How does oil splash lubrication benefit gearbox performance and maintenance?

A: Oil splash lubrication ensures continuous, efficient lubrication of moving parts inside the gearbox, minimizing wear, reducing friction, and extending service life. This design reduces the need for frequent manual maintenance and supports smooth, reliable operation.Q: What are the key benefits of using CMR Riduttori gear reducers in industrial settings?

A: Users benefit from high torque transmission, low noise levels, robust construction, a corrosion-resistant finish, and adaptable configurations. These qualities result in reliable operation, improved energy efficiency, long service life, and reduced downtime, enhancing productivity across industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry