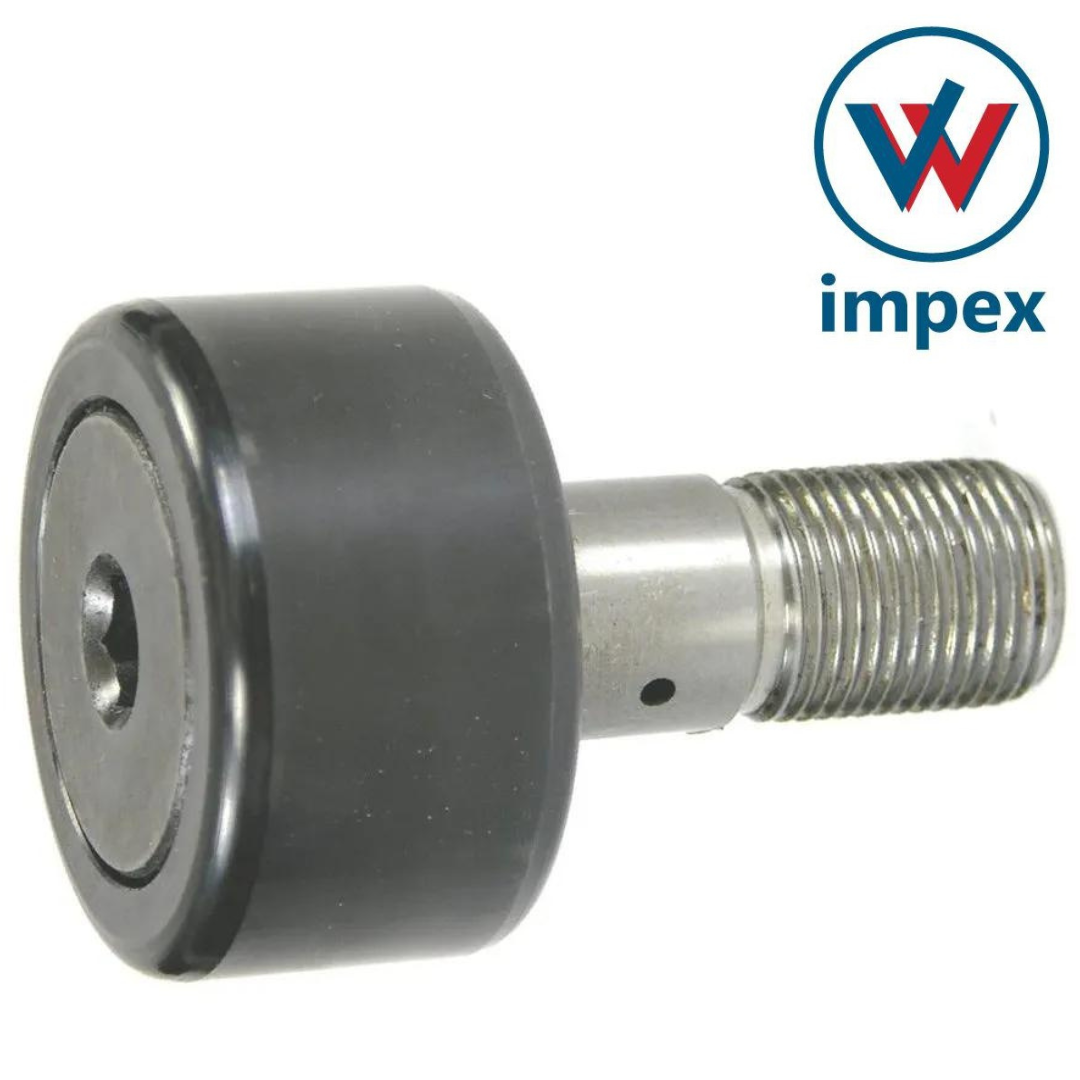

RBC Cam Follower Bearing

Price 8500 INR/ Piece

RBC Cam Follower Bearing Specification

- Precision Rating

- P0 / P6

- Retainer

- Yes

- Cage Material

- Steel

- Thickness

- 14 mm

- Lubrication Type

- Grease Lubrication

- Inside Diameter

- 10 mm

- Bearing Type

- Cam Follower

- Material

- Chrome steel

- Structure

- Stud Type

- Seals Type

- Double Seal

- Number Of Rows

- Single Row

- Bore Size

- 10 mm

- Outside Diameter

- 30 mm

- Limiting Speed

- 8000 rpm

- Load Capacity

- 1500 kg

- Corrosion Resistance

- Yes

- Static Load Rating

- 2400 kg

- Surface Finish

- Polished

- Application

- Automotive, Packaging Machinery, Industrial Automation

- Mounting Type

- Threaded Stud

- Inner Ring

- With Inner Ring

- Operating Temperature Range

- -30°C to +120°C

- Dynamic Load Rating

- 1500 kg

About RBC Cam Follower Bearing

RBC Cam Follower Bearing produces a full line of cam followers from 1/2 to 10 inch outside diameter sizes. Technical innovation and cost-saving features have distinguished RBC cam followers from competitors. Contact RBC engineers for assistance in solving difficult bearing challenges in your application.RBC Cam Follower Bearing:

- RBC

- RBY

RBC Cam Follower Bearing:

- S - Slotted Head

- S - L - Slotted Head and Sealed

- S - LW - Hexlube - relubricatable hex head

RBC Cam Follower Bearing Standard Stud Series:

- CS - L - Slotted Head and Sealed

- CS - LW - Hexlube - relubricatable hex head

Cam-Centric Adjustable Cam Followers:

- S - LWX - Cylindrical Hexlube - relubricatable hex head

- CS - LWX - Crowned Hexlube - relubricatable hex head

RBC Cam Follower Bearing - Heavy Stud:

- H - Slotted Head

- H - L - Slotted Head and Sealed

- H - LW - Hexlube - relubricatable hex head

Optimized for High-Load Applications

Engineered to support significant loads and rapid speeds, this cam follower bearing is tailored for demanding uses in automotive systems and packaging equipment. Its polished chrome steel construction and double-seal design enable consistent operation and extended service life under challenging conditions.

Superior Corrosion Resistance and Longevity

The cam follower bearing provides excellent corrosion protection, thanks to its high-quality materials and sealed structure. Users can count on dependable operation in environments where moisture or contaminants are present, minimizing maintenance needs and reducing downtime.

FAQ's of RBC Cam Follower Bearing:

Q: How is the RBC Cam Follower Bearing installed using the threaded stud?

A: This cam follower bearing utilizes a threaded stud mounting type, allowing for direct attachment to equipment or machinery frames. Simply insert the stud into the designated hole, then secure it with an appropriate nut and washer for stable fixation.Q: What applications are suitable for this cam follower bearing?

A: This bearing is ideal for use in automotive assemblies, packaging machinery, and various industrial automation systems. Its robust structure and high load ratings make it versatile for linear motion and rotary operations in heavy-duty settings.Q: When should I choose the double-seal cam follower design?

A: Opt for the double-seal version when you require added protection against dust, debris, and lubricant leakage. This design is particularly beneficial in environments exposed to contaminants or where longer maintenance intervals are desired.Q: Where can this cam follower bearing be sourced or supplied?

A: As a distributor, exporter, importer, supplier, and trader based in the United States, you can obtain these bearings directly from authorized RBC outlets or verified industrial suppliers to ensure genuine product quality and adherence to specifications.Q: What is the grease lubrication process for this bearing?

A: This bearing is pre-lubricated with grease, which ensures smooth operation and reduces the need for frequent maintenance. When servicing, use compatible high-quality grease and ensure the double seals remain intact to prevent contamination.Q: What benefits does the polished chrome steel and precision rating offer?

A: The polished chrome steel enhances corrosion resistance and overall durability, while the P0/P6 precision ratings provide accuracy in rotational performance. This combination ensures reliable, long-lasting functionality in precision applications.Q: How do the inner ring and steel cage contribute to bearing performance?

A: The integrated inner ring maintains accurate bearing alignment, while the steel cage ensures uniform roller spacing and load distribution. These features collectively support smoother motion, higher speed capability, and extended service life.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cam Followers Category

Smith Cam Follower Bearing

Price 7500 INR / Piece

Minimum Order Quantity : 5 Pieces

Outside Diameter : 35 mm

Bore Size : 15 mm

Material : Other, Bearing Steel

Thickness : 20 mm

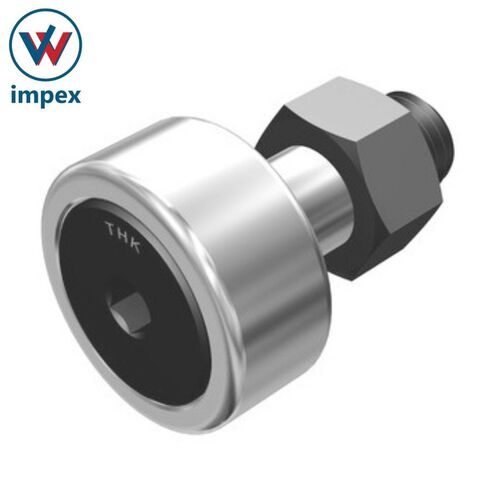

THK Cam Follower Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Outside Diameter : 32 mm

Bore Size : 12 mm

Material : Chrome steel

Thickness : 16 mm

JNS Cam Followers

Price 1200 INR / Piece

Minimum Order Quantity : 2 Pieces

Outside Diameter : 22 mm to 72 mm

Bore Size : 12 mm to 50 mm (various sizes available)

Material : Other, High Quality Bearing Steel

Thickness : Varies by model (typically 16 mm to 30 mm)

IKO Cam Follower Bearing

Price 560 INR / Piece

Minimum Order Quantity : 2 Pieces

Outside Diameter : 3 to 30 mm

Material : Other

Thickness : 3mm

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry