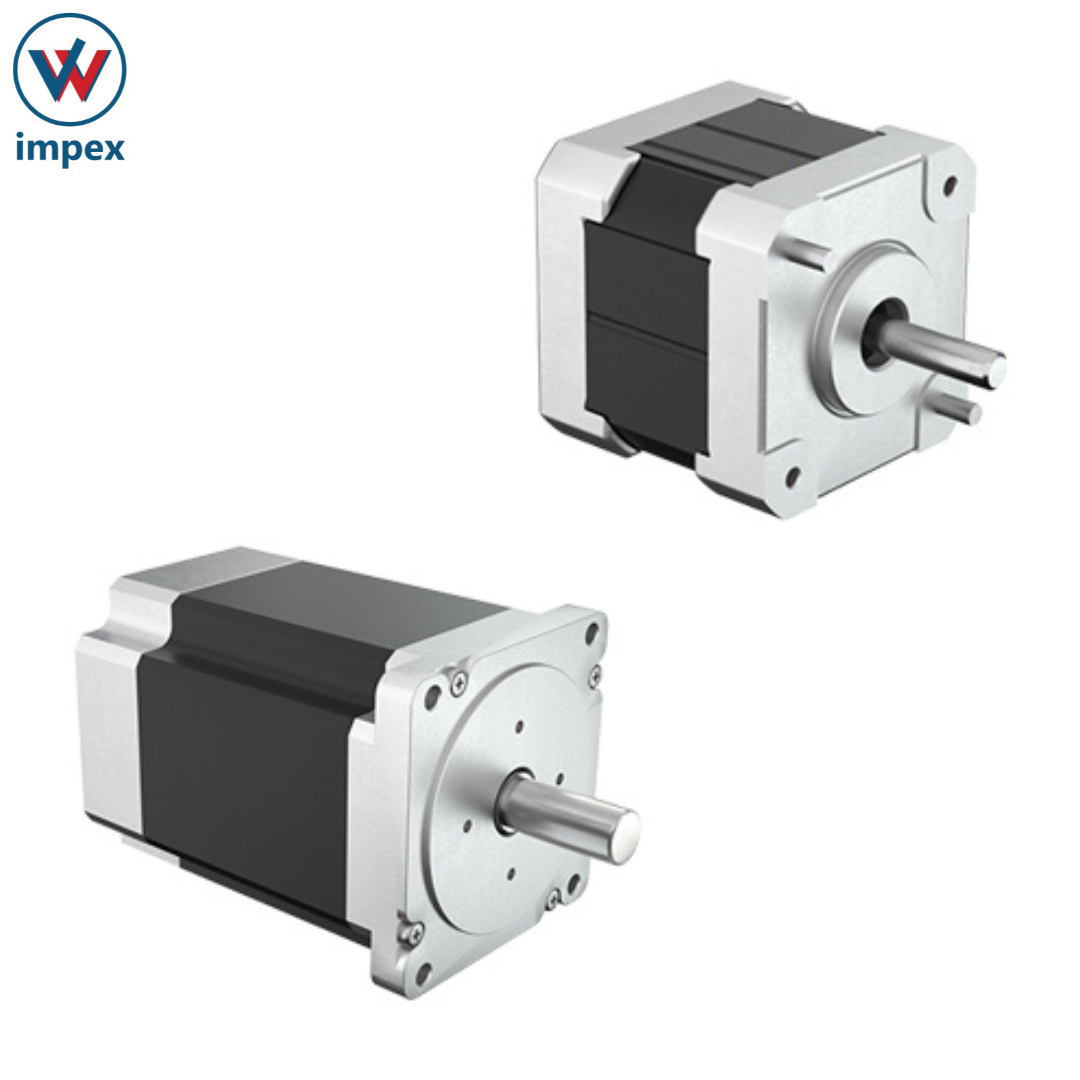

AHS Antriebstechnik Step Motors And Servomotors

Price 25000 INR/ Piece

AHS Antriebstechnik Step Motors And Servomotors Specification

- Inside Diameter

- As per model (matched with shaft size)

- Thickness

- Varies by model (typically 12 mm to 40 mm)

- Lubrication Type

- Grease Filled

- Retainer

- Integrated

- Cage Material

- Nylon or Steel

- Precision Rating

- P6, P5 (as required)

- Bearing Type

- Ball Bearing

- Material

- Alloy Steel with Coating

- Structure

- Industrial Grade Stepper / Servo Motor Assembly

- Seals Type

- Double Sealed

- Number Of Rows

- Single

- Bore Size

- 6 mm to 19 mm (varies by model)

- Outside Diameter

- 20 mm to 60 mm (varies by model)

- Limiting Speed

- Up to 6000 rpm

- Load Capacity

- Up to 220 N

- Step Angle

- 1.8°, 0.9° (Stepper Motor options)

- Operational Temperature

- -20°C to +80°C

- Encoder Resolution

- Up to 2500 PPR (Servo Motor only)

- Positioning Accuracy

- ±0.05 mm (Servo)

- Voltage Rating

- 24V, 48V (Stepper); 220V (Servo)

- Control Signal

- Pulse/Direction (Stepper), Analog/Digital (Servo)

- Motor Type

- Stepper Motor and Servo Motor

- IP Rating

- IP54

- Driver Requirement

- Separate Driver Unit required

About AHS Antriebstechnik Step Motors And Servomotors

Step Motors

Their 2-Phase Hybrid Step Motors hybrid steppers provide an excellent torque to frame size ratio. Optimized magnetic in combination with the rotor/stator design produce more torque and a higher acceleration.

They are available in different frame sizes of Nema 17, Nema 23 and Nema 34 and different stack lengths and have Holding torques from 0,25 Nm up to 40 Nm.

AHS High Torque Step Motors

The Nema 17, Nema 24 and Nema 34 series have holding torques from 0.3 Nm to 12 Nm.

The motors are manufactured in European factories to the highest quality standards and are designed for a long service life.

AHS Medium Torque

MT Series

The MT series is our most versatile series of stepper motors. Customer-specific special requests become over-the-counter standard motors with huge customization options.

Special connectors, special shafts, IP ratings, feedbacks, special windings.

Even with smaller quantities, many wishes are possible. The versions are almost unlimited and only a few basic engines are listed.

AHS Standard Step Motors

Their new Nema 23 Series with higher torque and Standard Connectors.

Servomotors

Their servo motors feature superior performance with a very high torque-to-inertia ratio and speeds up to 8,000 rpm for standard designs (up to 70,000 rpm for special designs).

Precision Engineered for Industrial Use

AHS Antriebstechnik stepper and servo motors stand out for their high-precision positioning and durability. Engineered with select step angles, superior material compositions, and advanced sealing features, these motors are tailored for efficiency and dependable long-term performance in industrial automation, packaging, and manufacturing environments.

Flexible Configurations and Versatile Performance

Available with a range of bore sizes (6 mm to 19 mm) and outside diameters (20 mm to 60 mm), these motors cater to varied operational needs. The use of ball bearings, grease-filled lubrication, and a robust steel or nylon cage ensures smooth operation and minimal maintenance. Each unit is compatible with separate driver units, supporting both pulse/direction and analog/digital control signals for easy integration into modern systems.

FAQ's of AHS Antriebstechnik Step Motors And Servomotors:

Q: How do I select the appropriate AHS stepper or servo motor for my application?

A: Begin by determining your application's voltage requirements, load capacity, precision level, and control method. For applications requiring precise incremental movements, select a stepper motor with the desired step angle. If closed-loop accuracy or higher speeds are needed, a servo motor may be preferable. Ensure the selected model's bore size and diameter match your mechanical setup.Q: What voltage ratings are available for AHS stepper and servo motors?

A: AHS stepper motors are offered in 24V and 48V versions, while servo motors operate at 220V. This allows for compatibility with a wide range of power supplies typically found in industrial and commercial settings.Q: When is it necessary to use an external driver unit with these motors?

A: Both AHS stepper and servo motors require a separate driver unit to function. The driver translates the control signals (pulse/direction for stepper, analog/digital for servo) into precise motion commands for the motor, ensuring accuracy and operational reliability.Q: Where can these motors be installed considering environmental factors?

A: With an IP54 rating and an operational temperature range from -20C to +80C, these motors are well suited for installation in dusty or moderately wet industrial environments. The double-sealed design further enhances protection against contaminants.Q: What are the primary benefits of using AHS stepper and servo motors?

A: Key benefits include high positioning accuracy (up to 0.05 mm for servo motors), robust alloy steel construction, and long service life due to ball bearing design and grease lubrication. The motors are designed for straightforward integration and superior performance, supported by reliable German engineering.Q: How is precision maintained during operation?

A: Precision is achieved through carefully engineered step angles (0.9 or 1.8 in steppers), high encoder resolutions up to 2500 PPR for servo motors, and precision bearings rated at P6 or P5. The ball bearing and integrated retainer structures minimize play and abrasion, helping to sustain accuracy throughout the motor's lifespan.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

Enduro Mast Guide Bearing

Price 9500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Number Of Rows : Single Row

Inside Diameter : 80 mm

Seals Type : Sealed

SIT Couplings & Locking Devices

Price 2500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel / Stainless Steel

Number Of Rows : Other, Single

Inside Diameter : Customizable as per requirement

Seals Type : Standard

AEGIS SGR Bearing Protection Ring

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special conductive microfibers, Aluminum housing

Number Of Rows : Single Row

Inside Diameter : Varies as per model

Seals Type : NonContact

Tandem Thrust Bearings

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry