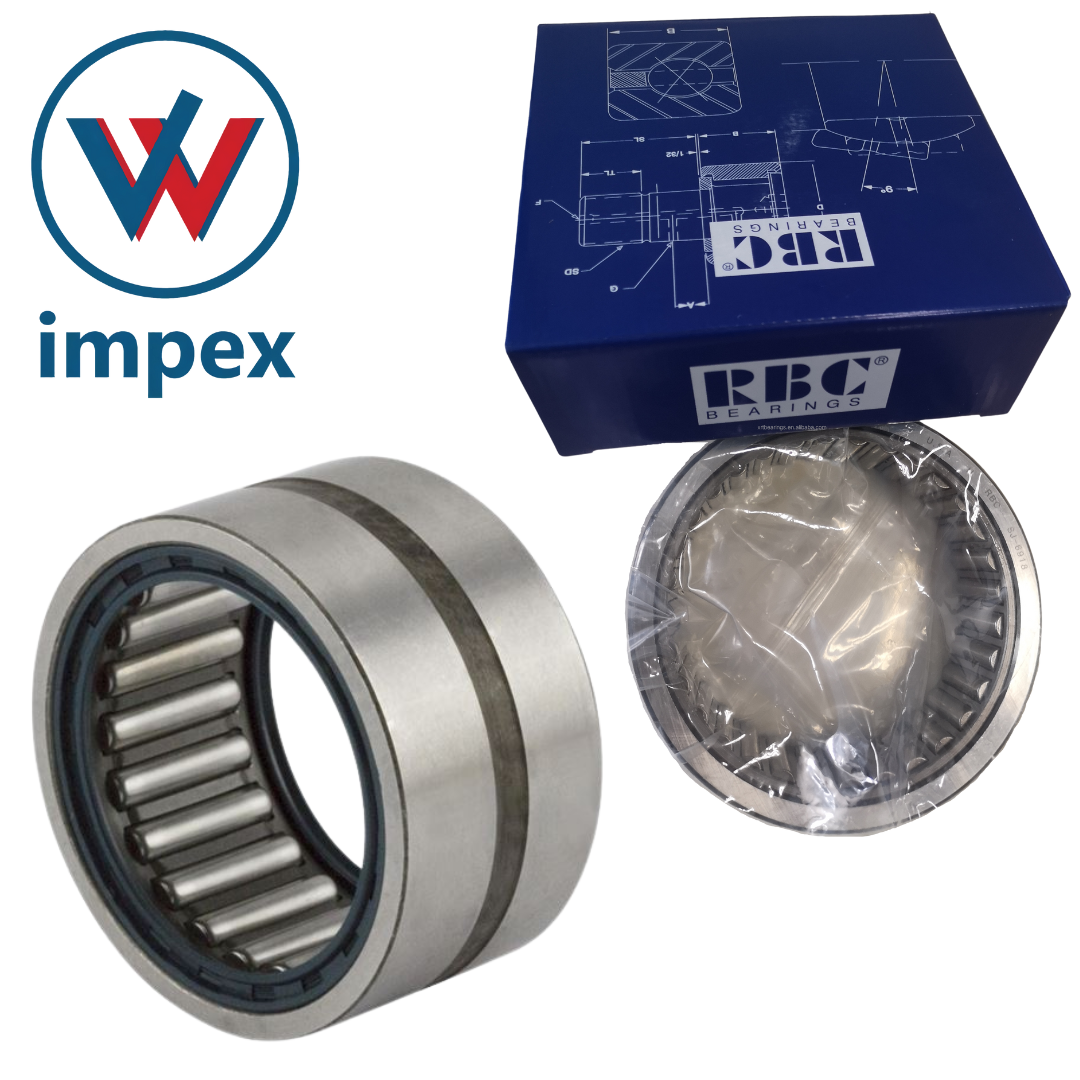

RBC Heavy Duty Needle Roller Bearing

Price 9900 INR/ Piece

RBC Heavy Duty Needle Roller Bearing Specification

- Thickness

- 22.23 mm

- Weight

- 0.38 kg

- Material

- Chrome Steel

- Ball Bearing Type

- Needle Roller Bearing

- Roller Bearing Type

- Heavy Duty Needle Roller

- Bushes Type

- Solid

- Structure

- Caged/Rolled

- Seals Type

- Sealed

- Number Of Rows

- Single

- Bore Size

- 38.1 mm

- Outside Diameter

- 57.15 mm

- Limiting Speed

- 7000 rpm

- Load Capacity

- 35000 N

- Inner Diameter

- 38.1 mm

About RBC Heavy Duty Needle Roller Bearing

RBCproduces an extensive heavy duty needle roller bearing product line from 1 inchouter ring diameter to 12 inch outer ring diameter. RBC has the capability tomanufacture special designs up to a 39 inch outer diameter.

TheRBC SJ series of Pitchlign heavy duty needle roller bearings are supplied instandard envelopes in both sealed and unsealed configurations. There are eightpossible seal configurations. The seals can include double or single seal withthe seal lip turned inward or outward. The seal can be mounted in the radiusend of the ring or the chamfered end of the ring for optimum mountingvariations.

RBC'spatented TJ Tandem Roller heavy duty needle roller bearings increase thecapacity of the standard Pitchlign SJ series from 10 percentage to 40 percentage while maintainingthe standard SJ envelope dimensions. The TJ design gives the heavy-duty needleroller bearing 37 percentage to 200 percentage greater life over a standard single pocket bearing.These bearings are also available in sealed and unsealed configurations.

RBCheavy duty needle roller bearings present a wide variety of designs. The TJTandem Roller and Pitchlign SJ Series heavy duty needle roller bearings areoffered in a double-row design. The TJ and SJ roller bearings can also bematched with an inner ring or run directly on a shaft. RBC inner rings can beused separately or as an inner race for complimentary SJ or TJ roller bearings.The inner rings range are through hardened and precision ground.

TheRBC SJ and TJ heavy duty needle roller bearing designs are easy to install andare especially beneficial in compact designs because of their high loadcapacity and small sectional height. The caged rollers allow for the RBC heavyduty needle roller bearings to be used in high-speed applications.

RBC heavy duty needle rollerbearings can be found in the following applications:

- Gear pumps

- Mud pumps

- Oil field pumping jacks

- Helicopter rotors and transmissions

- Telehandlers

- Material handling equipment

- Hydraulic pumps

- Sheave Blocks

- Hoist drum shaft

- Marine crankshafts and connecting rods

- Pipe handling tables in steel mill equipment

- Paper punch presses

- Planet gears and main shaft bearings of a clutch drive or mechanical press

- Calendar rolls in textile machinery

- Railroad tampering equipment

Key Performance Features

The RBC Heavy Duty Needle Roller Bearing boasts significant dynamic and static load ratings, supporting 42,000 N and 64,500 N respectively. Its chrome steel construction and steel cage enhance durability, while the sealed design helps prevent contamination and ensures reliable operation. The bearing's design allows high limiting speeds up to 7,000 rpm, making it suitable for high-performance industrial and construction applications.

Versatile Application & Usage

This bearing is ideal for integration into a variety of industrial machines and construction equipment, thanks to its heavy-duty structure and high load capacity. Its solid bush, press-fit mounting, and grease lubrication make installation straightforward and maintenance minimal. The product functions effectively in environments ranging from -20C to +120C, ensuring consistent performance even in demanding conditions.

FAQ's of RBC Heavy Duty Needle Roller Bearing:

Q: How is the RBC Heavy Duty Needle Roller Bearing installed in machinery?

A: The bearing is designed for a press-fit mounting process, allowing straightforward and secure installation into housings for industrial machinery or construction equipment. Proper alignment and use of recommended tools ensure maximum lifespan and optimal performance.Q: What are the primary benefits of using this needle roller bearing in construction equipment?

A: Key benefits include high dynamic and static load capacities, resistance to wear thanks to chrome steel construction, effective sealing for grease lubrication retention, and reliable operation across a wide temperature range, all of which enhance machine efficiency and durability.Q: When should I consider replacing the bearing in my equipment?

A: Replace the bearing if there are signs of excessive noise, vibration, overheating, or a noticeable decrease in performance. Routine inspection according to your machinery's maintenance schedule will help detect early signs of wear or potential failure.Q: Where can I source the RBC Heavy Duty Needle Roller Bearing in the United States?

A: You can acquire this bearing through authorized distributors, exporters, importers, suppliers, and traders operating across the United States. Bulk and single piece orders are both available to meet project-specific needs.Q: What process should I follow for bearing maintenance and lubrication?

A: Since the bearing is sealed and filled with grease, regular external cleaning and periodic inspection are recommended. If operating under severe conditions, check for signs of lubricant degradation and replace the unit if necessary to maintain peak performance.Q: How does the bearing's steel cage material affect its usage?

A: The steel cage enhances the bearing's ability to handle heavy radial loads and high rotational speeds, while maintaining structural integrity even in demanding environments. This makes it suitable for heavy-duty applications where reliability is critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Bearings Category

Gamet Bearings

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Bearing Steel (Chrome Steel)

Limiting Speed : Up to 12000 RPM

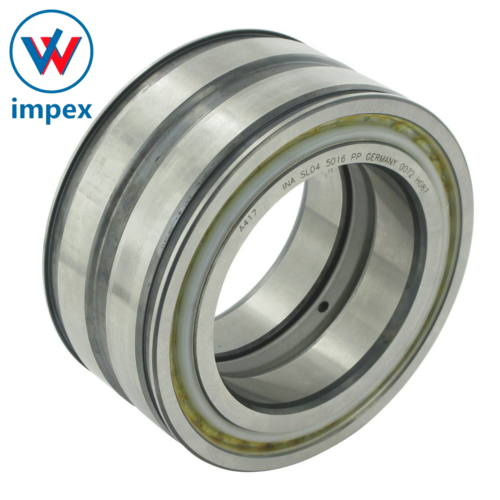

INA Cylindrical Roller Bearing

Price 5000

Minimum Order Quantity : 1 Piece

Material : Chrome Steel

Limiting Speed : 5300 RPM

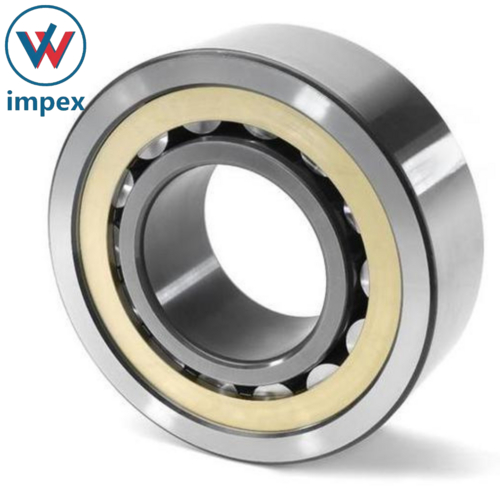

Cylindrical Roller Bearing

Price 5000

Minimum Order Quantity : 1 Piece

Material : Chrome Steel

Warranty : Typically 1 year or as per manufacturer

Limiting Speed : Varies depending on size and type typically listed in RPM

FAG Cylindrical Roller Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Warranty : Yes

Size : Different Available

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry