Gamet Bearings

Price 25000 INR/ Piece

Gamet Bearings Specification

- Weight

- Depends on size (0.25 kg to 10 kg)

- Thickness

- Varies by design

- Material

- Bearing Steel (Chrome Steel)

- Ball Bearing Type

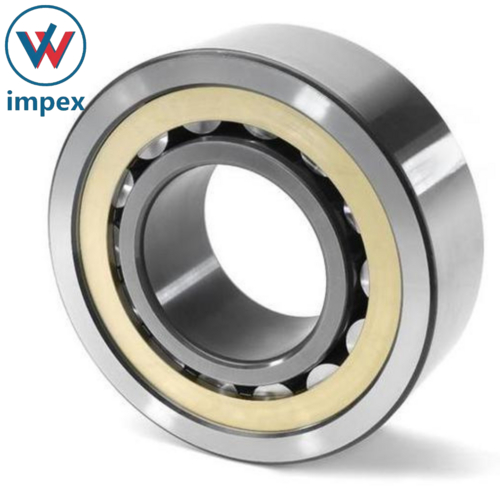

- Precision Angular Contact Ball Bearing

- Roller Bearing Type

- Tapered Roller Bearing

- Bushes Type

- Cylindrical Bush

- Structure

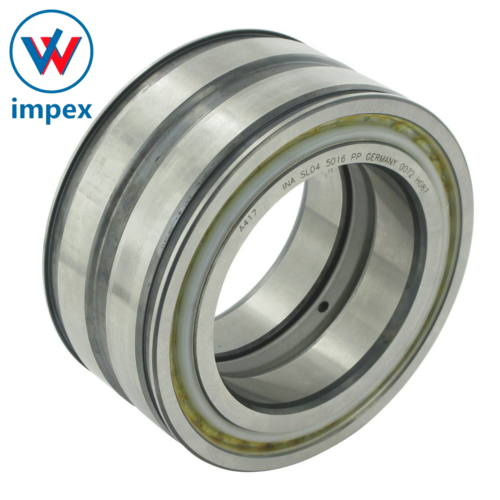

- Single Row/Twin Row/Tandem

- Seals Type

- Open/Sealed

- Number Of Rows

- Single, Double, Triple

- Bore Size

- 30 mm to 200 mm

- Outside Diameter

- 55 mm to 260 mm

- Limiting Speed

- Up to 12000 RPM

- Load Capacity

- High Load Rating

- Inner Diameter

- 30 mm to 200 mm

About Gamet Bearings

Gamet Bearingshave been manufacturing high precision tapered roller bearings for over forty years in their Colchester factory. Originally founded to serve the machine tool industry, Gamet has today expanded into other sectors of industry having high precision bearing requirements.

These include the coating of materials, photographic emulsions or adhesives, and the printing and packaging industries. Ongoing investment in new equipment and technology will ensure the continuing reputation of Gamet as a manufacturer of high precision, high quality bearings.

PLAIN CUP

The basic single row bearing can be used in light to medium loaded applications, and provides a simple, cost-effective arrangement.

BENEFITS

- Cone Bore Run-out tolerances ranging from 0.5 microns to 1.5 microns

- Comprehensive range of sizes from 25mm bore upwards

- Quality assured to ISO 9000 standards

- High quality bearing materials

The flanged cup version enables through boring of the housing for simplicity and accuracy.

BENEFITS

- Cone Bore Run-out tolerances ranging from 0.5 microns to 1.5 microns

- Comprehensive range of sizes from 25mm bore upwards

- Quality assured to ISO 9000 standards

This single row bearing has an extended outer ring, housing a number of springs. It is mounted in conjunction with either a single or double row bearing. As the outer race is free to slide in the housing, the spring force ensures that a constant bearing system preload is maintained despite thermal expansion due to varying temperature conditions.

BENEFITS

- Specialist design and manufacturing service available to meet your particular requirements

- Competitive delivery on most sizes

Double row bearings offer nearly twice the capacity of the equivalent single row bearing, and are therefore used in more heavily loaded applications.

The plain outer race enables this bearing to be used in a floating position to permit thermal expansion. As such it can replace a P type bearing when additional load capacity is required.

G type bearings can be pre adjusted to give GE double row bearings. This is achieved by fitting a spacer between the inner races to give the required assembly end play or pre load. The choice of setting is based upon a number of parameters such as speed, lubrication and applied loads. Spacer width is adjusted individually prior to despatch.

FLANGED CUP (H TYPE)

Double row bearings offer nearly twice the capacity of the equivalent single row bearing, and are therefore used in more heavily loaded applications.

This double row bearing has a flanged outer ring which locates the shaft axially. This can also simplify housing machining operations and overall design.

H type bearings can be pre adjusted to give HE double row bearings. This is achieved by fitting a spacer between the inner races to give the required assembly end play or pre load. The choice of setting is based upon a number of parameters such as speed, lubrication and applied loads. Spacer width is adjusted individually prior to despatch.

Unparalleled Precision for Demanding Applications

Gamet Bearings are meticulously crafted to serve the exacting needs of industries that require supreme accuracy and reliability, such as machine tool manufacturing and high-precision equipment. Each bearing undergoes stringent quality control and features ultra-precision tolerances, guaranteeing optimal performance under intensive operational conditions and high speeds.

Versatile Configurations and Customizable Options

Available in a range of structuressingle row, twin row, and tandem arrangementsour bearings are designed for flexibility in installation and operational requirements. Offering bore sizes from 30 mm to 200 mm and outer diameters up to 260 mm, Gamet Bearings can be tailored to specific engineering specifications, load ratings, and speed demands, making them ideal for various industrial uses.

Enduring Performance and Durability

All Gamet Bearings are made from robust bearing steel, finished through advanced grinding and polishing processes to ensure longevity and consistent operation at temperatures between -20C and 120C. Options for grease or oil lubrication further enhance operational life and efficiency, providing users with low-maintenance, high-output solutions.

FAQs of Gamet Bearings:

Q: How do I select the right Gamet Bearing for my application?

A: To choose the ideal bearing, assess your machinerys requirements including load capacity, operating speed (up to 12000 RPM), type of motion (angular contact or tapered roller), and dimensional needs. Our bearings cover bore sizes from 30 mm to 200 mm with several structural options, ensuring compatibility for both machine tool spindles and precision equipment.Q: What benefits do Gamet Bearings offer for precision machinery?

A: Gamet Bearings are renowned for ultra-precision tolerances, high load ratings, and consistent performance. These features ensure exceptionally smooth operation, extended service life, and reduced maintenance for precision machinery and spindles, even in demanding environments.Q: Where can I find distributor or supplier support for Gamet Bearings in the UK?

A: Gamet Bearings are distributed, exported, imported, and supplied by authorized partners and traders across the United Kingdom. You can contact us directly for references to official distributors or locate a supplier through our online directory.Q: What is the recommended lubrication method for Gamet Bearings?

A: Both grease and oil lubrication methods are suitable for Gamet Bearings. Your choice should depend on application requirements, operating speed, and temperature. Oil lubrication is often preferred at higher speeds and temperatures, while grease is ideal for lower maintenance and sealed environments.Q: When should I consider using open versus sealed bearing designs?

A: Open designs are recommended when easy access for lubrication and inspection is needed, while sealed types provide protection from contamination and require less maintenance. The selection depends on the operational environment and maintenance accessibility.Q: How are Gamet Bearings processed and finished for superior performance?

A: Each bearing is precision-ground and polished, ensuring tight dimensional tolerance and an exceptionally smooth surface. This finishing process minimizes friction, maximizes service life, and provides reliable operation, especially under ultra-precision requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Roller Bearings Category

RBC Heavy Duty Needle Roller Bearing

Price 9900 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Chrome Steel

Cylindrical Roller Bearing

Price 5000

Minimum Order Quantity : 1 Piece

Material : Chrome Steel

Warranty : Typically 1 year or as per manufacturer

FAG Cylindrical Roller Bearing

Price 3500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : SS

Warranty : Yes

Size : Different Available

Usage : Industrial

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry