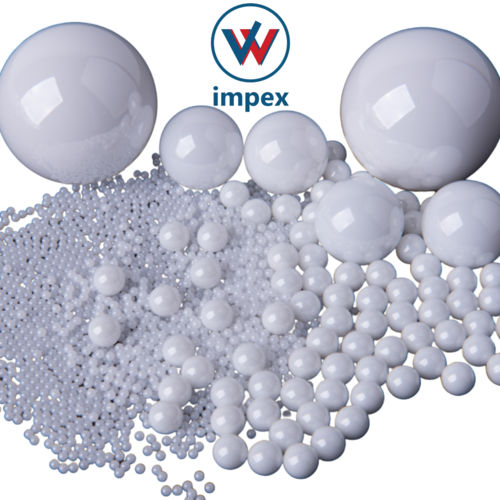

Zirconia (ysz) Grinding Media ( Balls)

Zirconia (ysz) Grinding Media ( Balls) Specification

- Inside Diameter

- N/A (solid balls)

- Lubrication Type

- Dry or wet grinding

- Precision Rating

- High

- Thickness

- Varies by diameter

- Material

- Yttria-stabilized Zirconia (YSZ)

- Structure

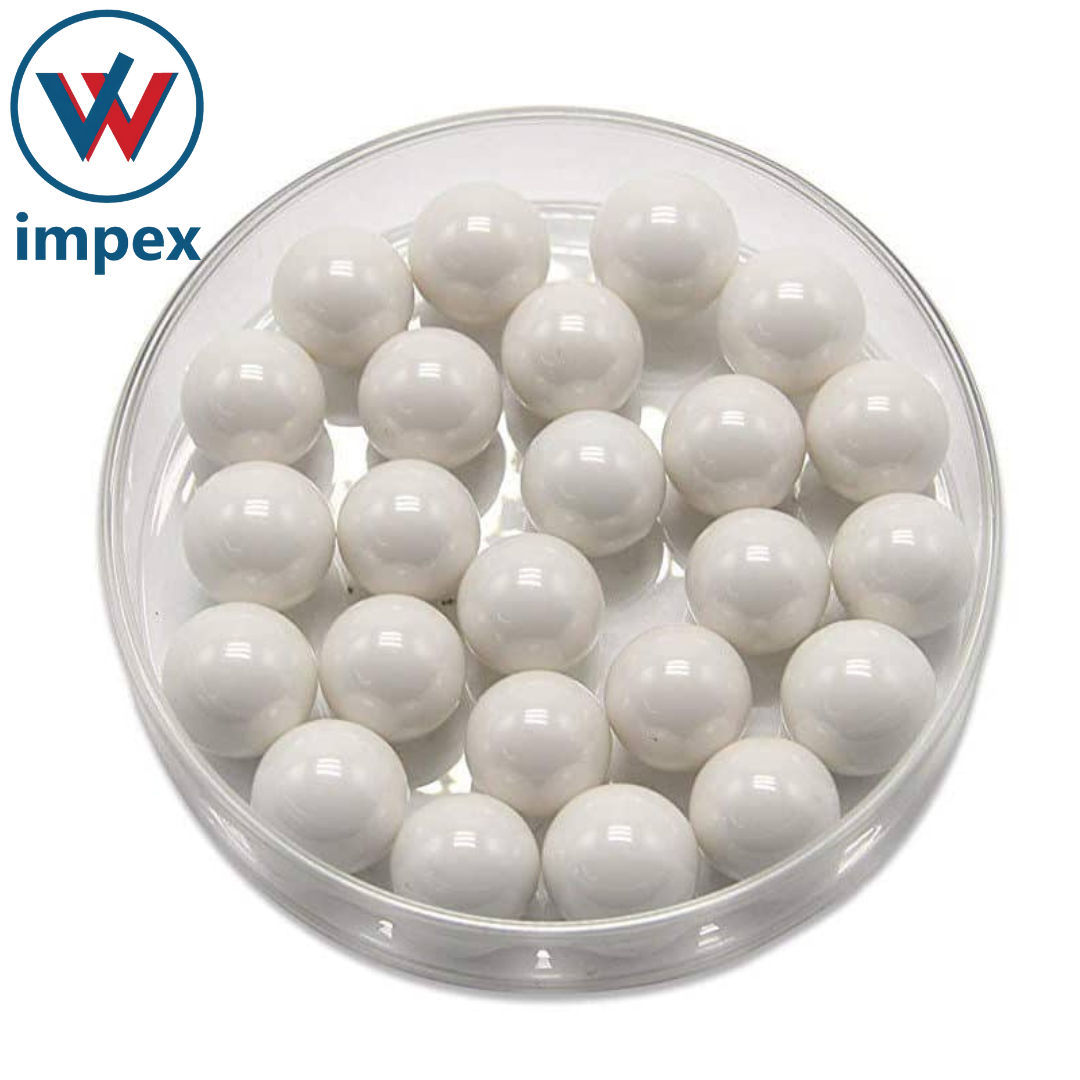

- Solid spherical

- Number Of Rows

- Single

- Bore Size

- Customizable

- Outside Diameter

- 0.5 mm to 25 mm (standard available sizes)

- Load Capacity

- High density, suitable for heavy impact

Zirconia (ysz) Grinding Media ( Balls) Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- Piece

- Delivery Time

- Days

- Certifications

- Yes

About Zirconia (ysz) Grinding Media ( Balls)

An Efficient, Longer-Lasting & Virtually Contamination-Free Solution for Ceramic Grinding & Milling

Zirconia (YSZ) grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic materials. Zirconia grinding media provides a virtually contamination-free ball milling solution for a variety of industries.

SPHERICAL ZIRCONIA (YSZ) GRINDING MEDIA0.3mm, 0.5mm, 0.8 mm 1mm, 1.5 mm ,2 mm,3mm, 5mm,6.5mm,10mm,12mm,

15mm,20mm,25mm,30mm.

CYLINDRICAL ZIRCONIA (YSZ) GRINDING MEDIA

5mm,7.5mm,10mm,12mm,15mm,20mm

Advantages of Zirconia Grinding Media

* Ultra low wear loss as a result of the transformation-toughening mechanism unique to the yttria stabilized zirconia (YSZ) material system.

* Higher grinding efficiency and reduced grinding time due to zirconias higher density (compared with alumina and glass).

* Most durable grinding material, reducing operational cost in the long run. Wear rate substantially lower than Al2O3, CeO2-ZrO2, and MgO-ZrO2 grinding media.

* Suitable for high velocity operations and wet grinding operations.Applications of Zirconia Grinding Media

* Iron- and chrome-based magnetic materials (for audio/video recording tapes) and other magnetic materials.

* Electronic-grade ceramics (ferroelectric, piezoelectric, dielectric, capacitors, sensors, etc.), advanced structural ceramics, and other ceramic ingredients.

* Nanostructured and superfine powders.

* Toner materials for photocopiers and laser printers.

* Inks, dyes, paint, and other pigments.

* Pharmaceutical, food, chemical, and textile applications.

* Lab milling operations demanding minimized contamination from milling media.Criteria in Selecting Size of Zirconia Grinding Media

* Larger-sized media are more efficient in breaking up large particles.

* Smaller media are more efficient in milling smaller particles because of higher effective contact area.

* Larger media sizes are favored in many conventional ball mills. Smaller sizes are more appropriate for attritors. For example, 5mm media are used in many attrition mill applications, whereas 10-15 mm may be a good start for a lab ball mill. For small-media mills, media sizes are typically smaller than 2 mm.

* Another important criterion in selecting media size is the gap size between stirring arms and mill walls. Media size should be significantly smaller than the gap size to prevent jamming.

Exceptional Wear Resistance and Low Contamination

Zirconia (YSZ) grinding media deliver outstanding wear resistance and minimize contamination, making them ideal for prolonged use in processing sensitive materials. Their smooth, solid spherical design maintains purity even through repetitive grinding cycles.

Versatile Compatibility and Precision Engineering

These balls accommodate dry or wet grinding and fit seamlessly into all types of grinding machinery. With high precision ratings and customizable sizes, they support heavy-impact operations in industrial, laboratory, and research settings across India.

Chemical and Thermal Stability for Demanding Conditions

YSZ grinding media withstand harsh acidic and alkaline processes and perform reliably at elevated temperatures up to 1000C. This ensures uninterrupted operation in chemical, pharmaceutical, electronic, and advanced material industries.

FAQs of Zirconia (ysz) Grinding Media ( Balls):

Q: How are Zirconia (YSZ) grinding media balls used in milling and dispersing applications?

A: These balls facilitate the grinding, milling, and dispersing of materials by providing consistent impact and shearing action within mills or dispersing equipment. Their high density and hardness result in efficient particle size reduction, making them highly valuable in laboratories and industrial setups.Q: What benefits do Zirconia (YSZ) grinding balls offer compared to other materials?

A: YSZ grinding media offer ultra-low contamination, superior wear resistance, and excellent chemical and thermal stability. Their high fracture toughness and smooth, non-porous surface ensure long service life and maintain the integrity of sensitive materials.Q: When should I choose Zirconia (YSZ) grinding media?

A: Opt for YSZ grinding balls if your application requires extended durability, chemical resistance, or minimal contaminationparticularly in the pharmaceutical, nanomaterial, or electronic sector where material purity is critical.Q: Where can Zirconia (YSZ) grinding balls be effectively utilized?

A: They are widely used in industries such as ceramics, pharmaceuticals, electronics, pigments, and advanced materials processing, as well as research institutions and laboratories, especially throughout India.Q: What is the process for selecting the correct Zirconia (YSZ) ball size for my machinery?

A: Select ball size based on the target particle size, milling intensity, and machinery type. Standard diameters range from 0.5 mm to 25 mm, and custom sizes are available to ensure optimal grinding performance and compatibility.Q: How does chemical stability of Zirconia (YSZ) balls enhance grinding applications?

A: Their resistance to acids and alkalis allows them to be used in aggressive chemical environments without deteriorating, ensuring consistent grinding performance and protecting the processed materials from unwanted reactions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ceramic Bearings & Ceramic Balls Category

Hybrid Ceramic Bearings

Price 6500 INR / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Single Row

Bore Size : 6 mm

Material : Other, Ceramic Balls with Stainless Steel Rings

Precision Rating : P6

Silicon Nitride (Si3N4) Ceramic Balls

Price 300

Minimum Order Quantity : 100 Pieces

Number Of Rows : Other, Single

Bore Size : Customized (Standard sizes available)

Material : Other, Silicon Nitride (Si3N4)

Precision Rating : ABEC1 to ABEC9

Full Ceramic Ball Bearings

Price 800

Minimum Order Quantity : 10 Pieces

Number Of Rows : Single Row

Bore Size : To be provided

Material : Ceramic

Precision Rating : To be provided

Si3n4 Full Ceramic Bearing of Full Complement

Price 9500 INR / Piece

Minimum Order Quantity : 1 Piece

Number Of Rows : Single Row

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry