Winkel Combined Bearings

Price 10000 INR/ Piece

Winkel Combined Bearings Specification

- Thickness

- 36 mm

- Weight

- 1.5 kg

- Material

- Alloy Steel

- Ball Bearing Type

- Double Row

- Roller Bearing Type

- Combined Roller

- Bushes Type

- Cylindrical

- Structure

- Angular Contact

- Seals Type

- Sealed

- Number Of Rows

- 2

- Bore Size

- 30 mm

- Outside Diameter

- 80 mm

- Limiting Speed

- 2500 RPM

- Load Capacity

- 8 kN

- Inner Diameter

- 30 mm

- Operating Temperature Range

- -20°C to +80°C

- Usage

- Material handling, lifting systems, automation

- Coating

- Corrosion protected finish

- Lubrication

- Pre-lubricated with lithium grease

- Application

- Suitable for combined radial and axial loading

- Mounting Position

- Any orientation

About Winkel Combined Bearings

Winkel Combined Bearings since more than 30 years we are working in the field of linear systems and material handling. We are a market leader in the field of heavy load linear systems and have delivered thousands of handling systems. Behind WINKELs success are more than 130 employees working in development, purchasing, administration, production, sales and customer service. We are proud of these employees because every day they give unrivaled support to our customers ensuring the best solutions are provided with a high degree of technical and commercial awareness.

Reduces your designing and production costs.

Features

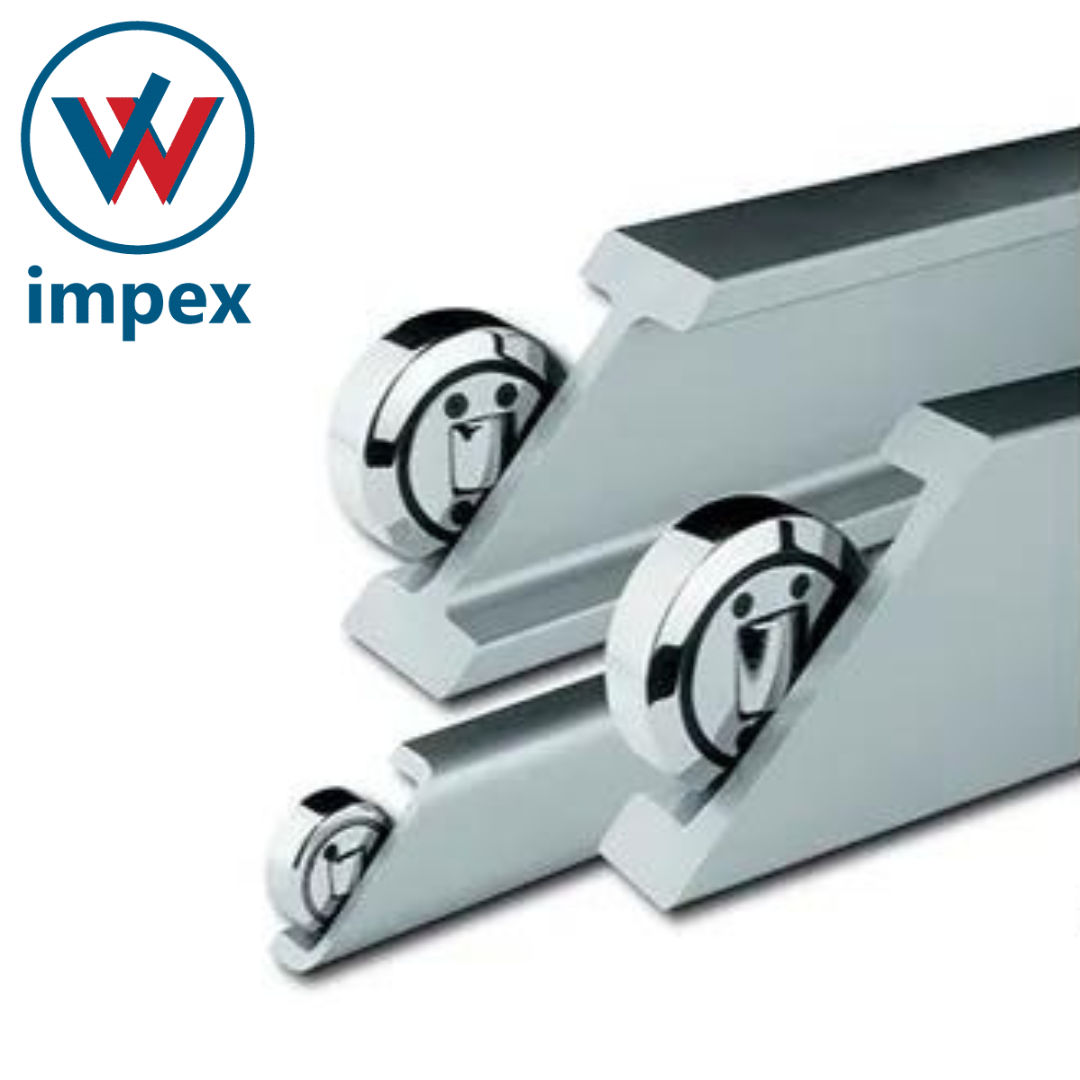

- Can take up high radial and axial loads

- Strong profiles for high stat. and dynamic loads

- Best dispersion of forces in the profiles

- Longer lifetime for bearings and profiles

- Economical assembling by welding bolt

- Bearing components are easily exchangeable

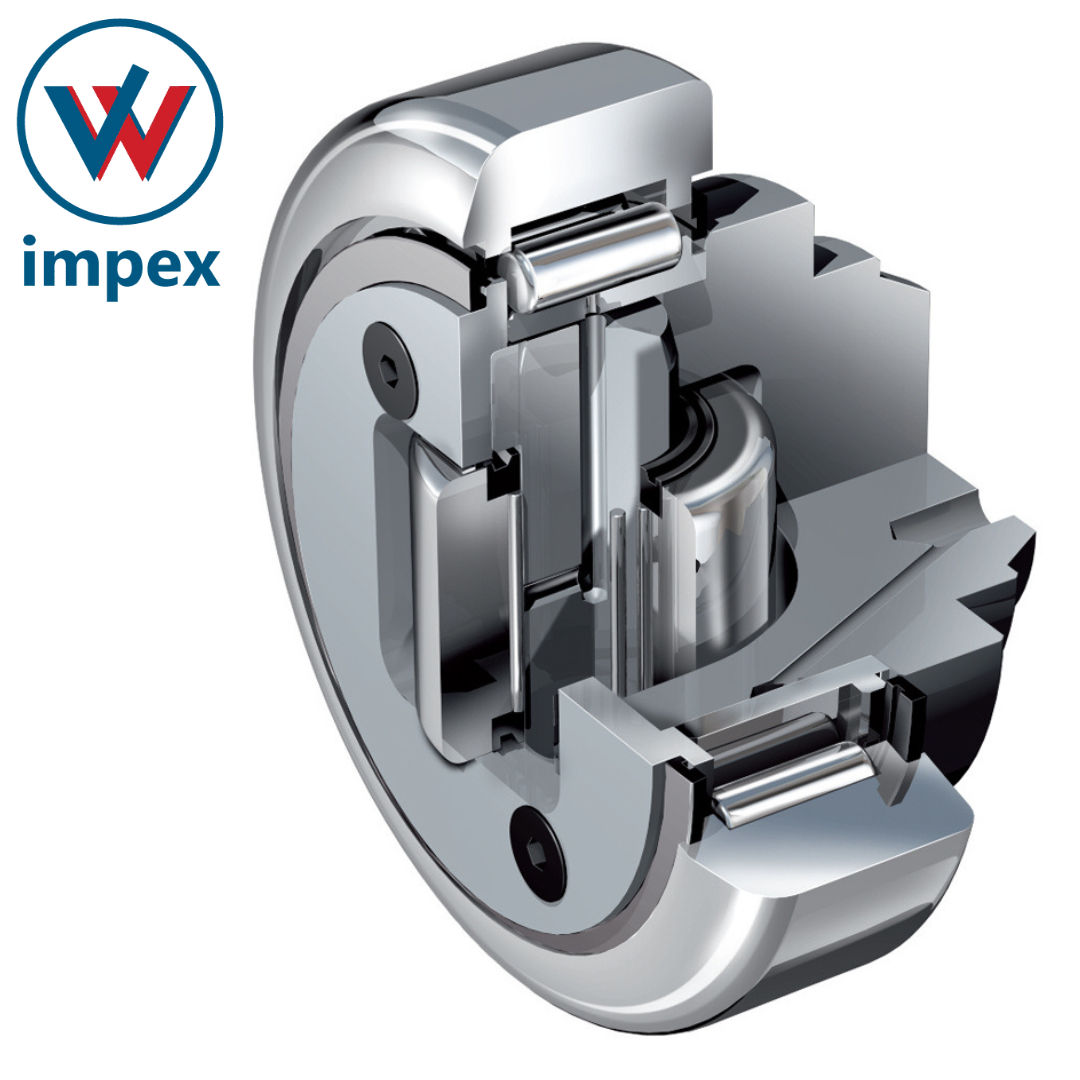

Advanced Design for Demanding Applications

Winkel Combined Bearings feature a robust angular contact structure with double row ball bearing and combined roller bearing types. This design ensures exceptional performance in applications involving simultaneous radial and axial loads, enhancing system longevity and efficiency.

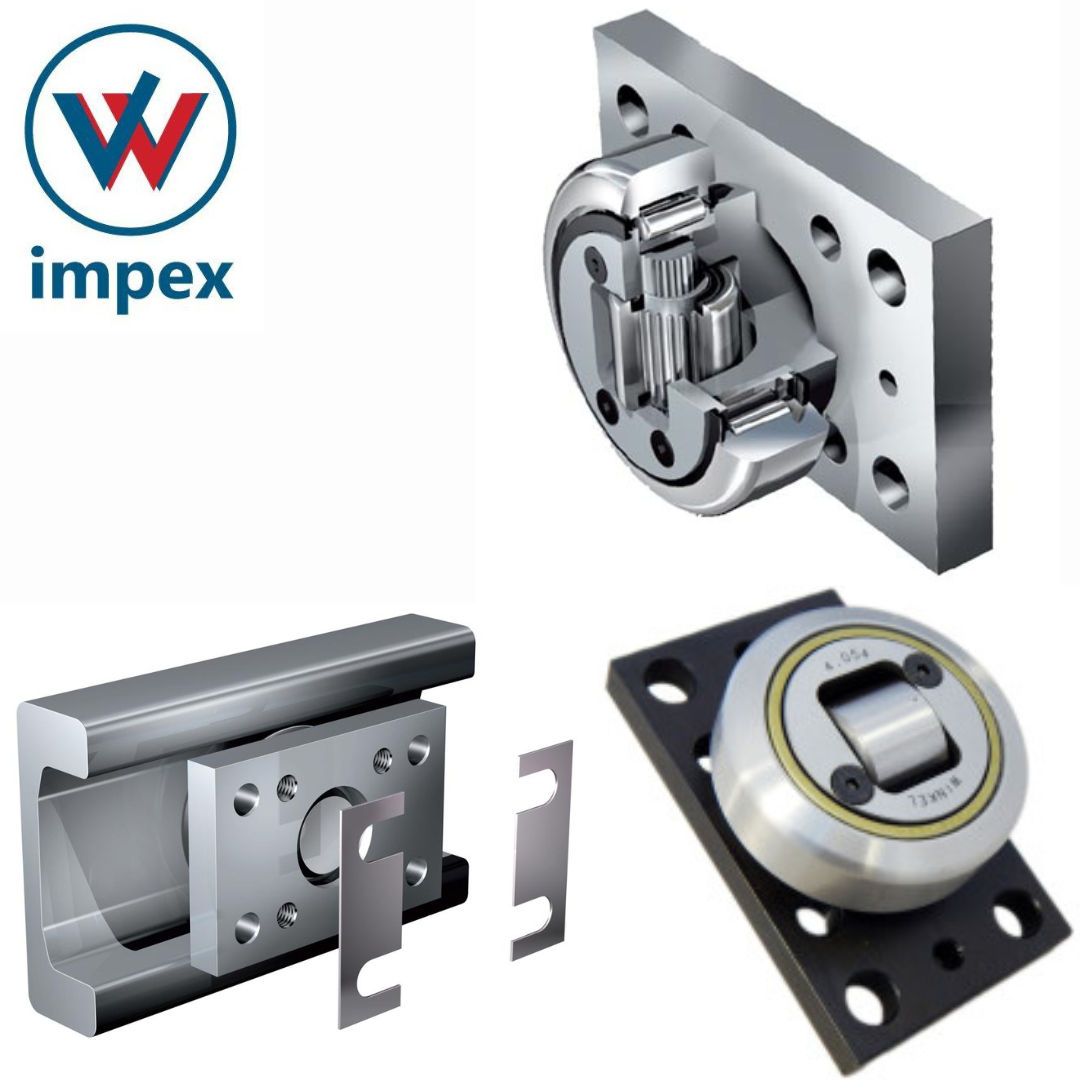

Versatile Mounting and Reliable Operation

Engineered for flexibility, these bearings support installation in any orientation without sacrificing operational integrity. They come pre-lubricated, reducing maintenance demands while ensuring long-lasting, smooth motion even in challenging industrial environments.

Corrosion Protection and High Durability

A special corrosion-protected finish protects the alloy steel housing, enabling dependable usage in material handling and automation sectors. Sealed construction guards against contaminant ingress, further boosting longevity and performance.

FAQs of Winkel Combined Bearings:

Q: How are Winkel Combined Bearings installed in industrial equipment?

A: Winkel Combined Bearings can be mounted in any orientation, providing great flexibility during installation. The pre-lubricated, sealed design ensures smooth operation regardless of the mounting position, making them easy to integrate into a wide range of machinery such as material handling systems and automated lifting equipment.Q: What makes these bearings suitable for combined radial and axial loads?

A: These bearings incorporate an angular contact structure with double row ball bearings and combined rollers. This sophisticated arrangement allows them to efficiently absorb and transmit both radial and axial forces, making them ideal for demanding industrial tasks.Q: When should the lubrication of the bearing be checked or replaced?

A: Since these bearings are pre-lubricated with high-performance lithium grease and feature sealed housings, lubrication maintenance is significantly reduced. Generally, under normal operating conditions within the specified temperature range, re-lubrication is rarely required. However, periodic inspection is recommended for prolonged or extreme usage.Q: Where can Winkel Combined Bearings be used most effectively?

A: They are particularly effective in material handling, lifting systems, and automation setups, especially in environments where both radial and axial loads are prevalent. Their corrosion-protected finish and temperature tolerance further suit them for diverse industrial facilities.Q: What is the benefit of the corrosion-protected finish on these bearings?

A: The corrosion-protected finish enhances the bearings resistance to harsh environmental conditions, minimizing the risk of rust and premature wear. This extends the operational life, especially in settings exposed to moisture, dust, or chemicals.Q: How does the sealed design improve the lifespan of Winkel Combined Bearings?

A: The sealed construction prevents dust, debris, and moisture from entering the bearing, thereby protecting the internal lubricants and components. This reduces the need for maintenance and assures sustained performance over prolonged operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Combined Bearings Category

Faro Combined Bearing

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : MS

Usage : Industrial

INTECOM COMBINED BEARINGS

Price 5000 INR / Piece

Minimum Order Quantity : 2 Pieces

Usage : LIFTING APPLICATIONS

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry