Rexnord Coupling And Gears

Price 5000 INR/ Piece

Rexnord Coupling And Gears Specification

- Lubrication Type

- Grease Lubrication

- Retainer

- Metallic

- Inside Diameter

- 38 mm

- Cage Material

- Steel

- Thickness

- Standard

- Precision Rating

- ISO Standard

- Bearing Type

- Spherical Roller

- Material

- Alloy Steel

- Structure

- Gear Coupling

- Seals Type

- Grease Seal

- Number Of Rows

- Single

- Bore Size

- 38 mm

- Outside Diameter

- 95 mm

- Limiting Speed

- 4000 RPM

- Load Capacity

- High

- Temperature Range

- -20°C to +120°C

- Torque Rating

- Upto 10000 Nm

- Coupling Type

- Rigid/Flanged Gear Coupling

- Compliance

- DIN / AGMA Standard

- Maintenance

- Low

- Finish

- Anti-corrosive Coating

- Max. Misalignment

- Up to 1.5° Angular

- Application

- Industrial (Pumps, Compressors, Gearboxes)

About Rexnord Coupling And Gears

Rexnord has provided solutions for couplings. Customers receive the benefits of our experience through a broad line of couplings that are manufactured for quality, reliability and easy maintenance. Complemented by a team of sales and service specialists, Rexnord delivers the lowest total cost of ownership in the industry. Choose from many brands, like Falk, Steelflex, Thomas and Addax.

Rexnord offers a broad range of clutches for customers, including Stearns Clutches, Marine Gear Drive Clutches, BSD Overload Clutches, and BSD Pressure Operated Clutches for a variety of applications. Stearns features clutches for industries including material handling, mining, energy and wind energy. BSD multi-disc torque limiter clutches are mechanical, infinitely-variable overload protections suitable for applications with high speeds and high slipping frequencies. BSD pressure operated clutches are friction clutches most efficiently used in industrial equipment where systems are to be engaged or disengaged. Tested and proven for more than 70 years, Rexnord also offers the Falk B7B Marine Air Clutch. A reliable engine-to-gear connection.

Engineered for Industrial Reliability

Rexnords rigid/flanged gear couplings are specifically crafted for intensive operations in industrial settings. Their superior alloy steel construction, anti-corrosive finish, and ISO precision rating provide lasting durability and consistent performance, even in environments exposed to harsh conditions. With a sealing system for grease lubrication and a robust metallic retainer, these couplings offer reliable, long-term operation with minimal maintenance.

Efficient Performance and Flexible Alignment

Designed to handle up to 10,000 Nm torque and high speeds up to 4000 RPM, these gear couplings also manage angular misalignments up to 1.5, ensuring smooth power transmission in critical applications. Their precision-engineered structure, including a spherical roller bearing system, supports high radial and axial loads for pump, compressor, and gearbox operations.

FAQs of Rexnord Coupling And Gears:

Q: How does the Rexnord rigid/flanged gear coupling handle misalignment in industrial machinery?

A: The coupling can compensate for up to 1.5 of angular misalignment, which helps prevent stress on connected equipment such as pumps and gearboxes, ensuring smooth operation and reducing downtime.Q: What are the primary benefits of choosing a Rexnord gear coupling with anti-corrosive coating?

A: The anti-corrosive coating enhances the couplings durability in harsh environments, protecting it from rust and chemical exposure and extending its service life in industrial settings.Q: When should grease lubrication be performed on Rexnord gear couplings?

A: Routine lubrication intervals should be established based on the machines duty cycle, although the couplings grease-sealed design and low maintenance requirements reduce the frequency of servicing compared to traditional couplings.Q: Where can Rexnord couplings be installed within industrial facilities?

A: These couplings are well-suited for installation in pumps, compressors, and gearboxes, making them ideal for heavy-duty industrial applications where reliable power transmission and alignment compensation are required.Q: What is the installation process for Rexnord flanged gear couplings?

A: The coupling is designed for straightforward installation, utilizing a single row gear structure and standard thickness. The bore and outside diameter measurements (38 mm and 95 mm respectively) are set to fit standard shaft sizes, ensuring modularity.Q: How does compliance with DIN/AGMA and ISO standards impact performance?

A: Compliance guarantees that the couplings meet stringent international requirements for quality, strength, and precision, translating to consistent performance and compatibility with global industrial systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Couplings & Gears Category

Neugart Planetary Gearbox

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Permanent grease lubrication

Inside Diameter : Depends on shaft size

Limiting Speed : Up to 6000 rpm

Structure : Planetary Gearbox

Renold Clutch And Couplings

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Grease Lubrication

Inside Diameter : According to bore size

Limiting Speed : 4000 rpm

Structure : Clutch Coupling

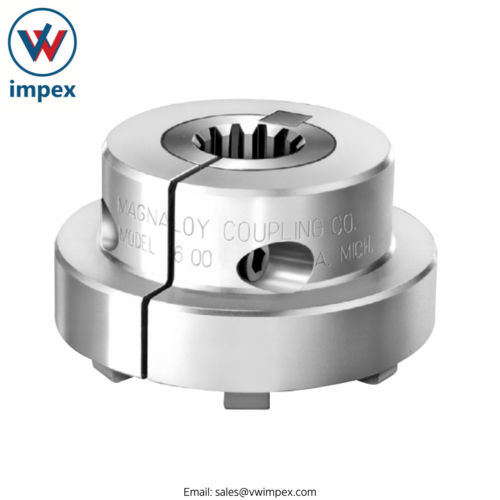

Magnaloy Flexible Drive Couplings And Inserts

Price 6000 INR / Piece

Minimum Order Quantity : 2 Pieces

Lubrication Type : Other, No lubrication required

Inside Diameter : Corresponds to bore size

Limiting Speed : Up to 14,000 RPM (depending on size)

Structure : Flexible Drive Coupling

Samiflex Elastic Couplings

Price 8000 INR / Piece

Minimum Order Quantity : 1 Piece

Lubrication Type : Other, Dry/NonLubricated

Inside Diameter : Custom/As per requirement

Limiting Speed : Up to 8100 RPM

Structure : Flexible Jaw Coupling

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry