OAV Air Bearing

Price 45000 INR/ Piece

OAV Air Bearing Specification

- Cage Material

- Non-metallic

- Precision Rating

- P4

- Lubrication Type

- Air Lubricated

- Thickness

- 20 mm

- Inside Diameter

- 40 mm

- Retainer

- Composite

- Bearing Type

- OAV Air Bearing

- Material

- Stainless Steel / Aluminum

- Structure

- Air Bearing

- Seals Type

- Non-contact

- Number Of Rows

- Single

- Bore Size

- 40 mm

- Outside Diameter

- 99 mm

- Limiting Speed

- Max 4500 rpm

- Load Capacity

- 400 N

- Static Load Rating

- 500 N

- Mount Type

- Flanged Mount

- Operating Temperature Range

- -20°C to +80°C

- Application

- High-precision rotary and linear motion

- Noise Level

- Ultra Low (Zero Contact)

- Dynamic Load Rating

- 350 N

About OAV Air Bearing

OAV Air Bearing is committed to providing their customers with the most precise bearing systems available.

Advancing technologies have led to major breakthroughs in existing industries and given way to new, emerging markets. These developments have increased the need for precision tools and equipment, fueling the demand for precision bearing systems.

The error motion of bearings with mechanical contact are dominated by the geometric and surface finish errors of their components. OAV Air Bearings however, do not have mechanical contact between elements and benefit from an air-film averaging effect. Furthermore, due to an absence of mechanical contact, the OAV Air Bearing has virtually no friction to generate heat and cause wear.

OAV Air Bearings was founded as a division of Aviation Company. Today, the company is still in owners hand and under owner management and is located in Princeton, NJ.

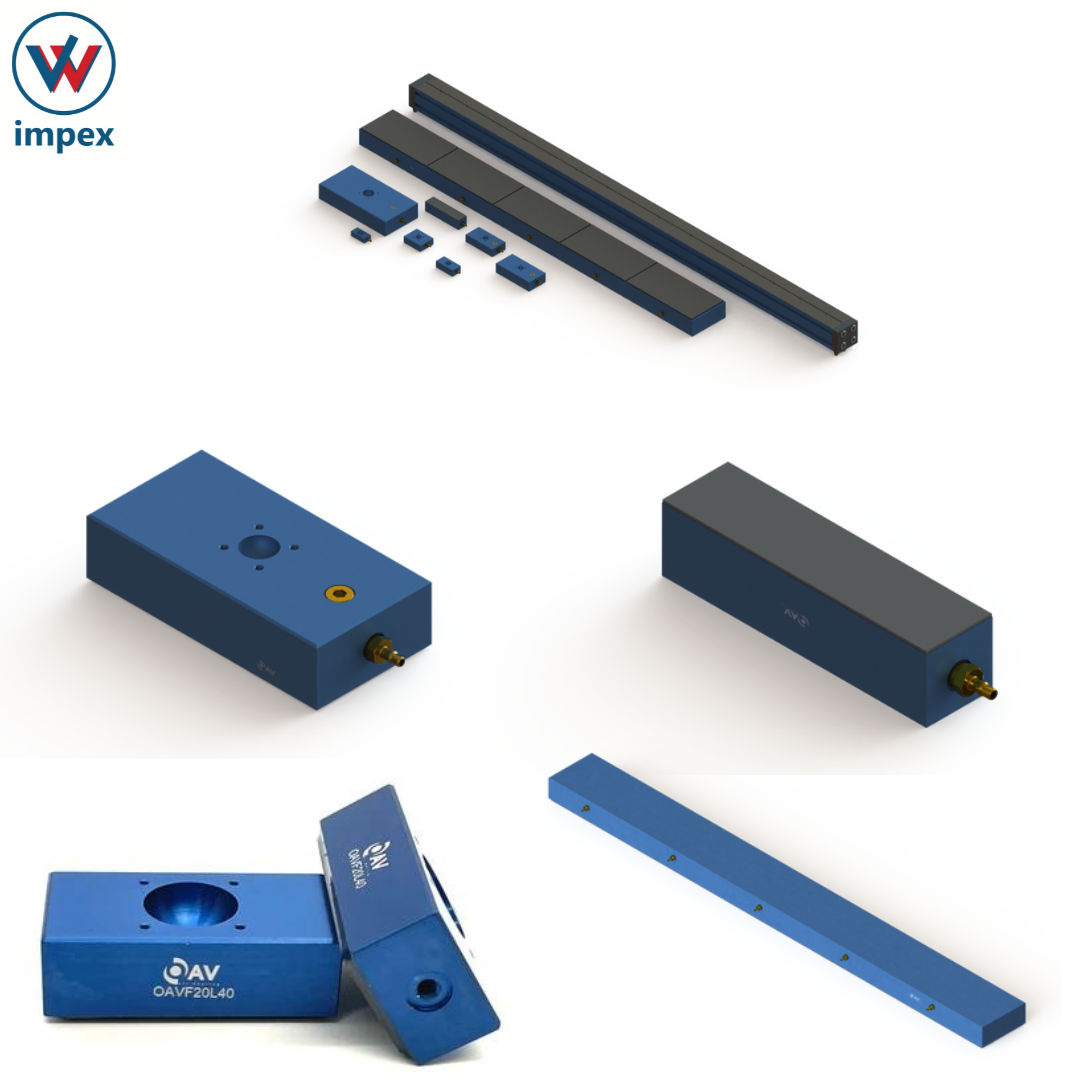

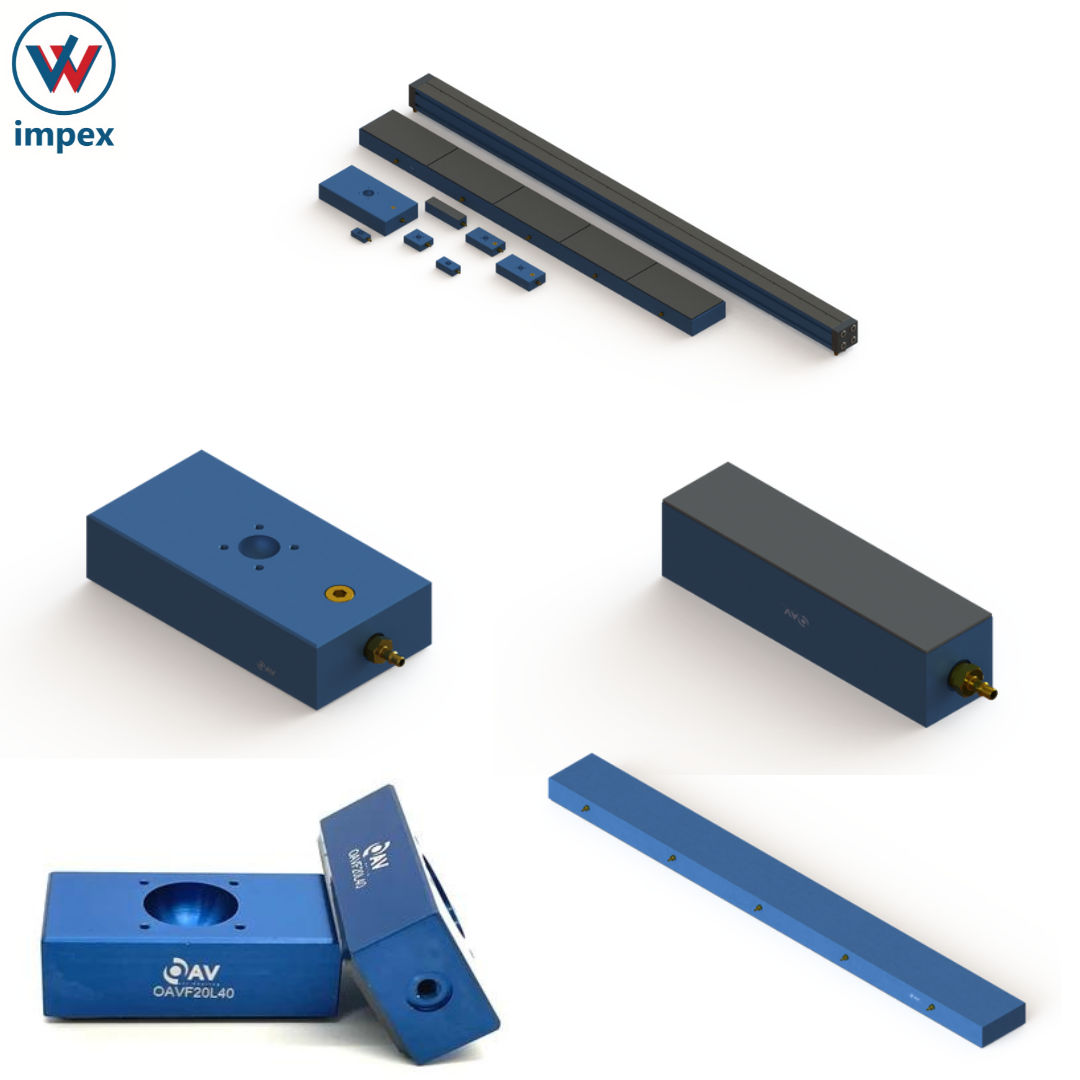

Air Bushings

Through recent technical advances, Air bearings offer inherent advantages over traditional bearings as well as create opportunity for a much broader range of applications. ButOAVAir bearings offer more: integrated Air bearings, Aerospace materials and standardization of product and proven performance in the most demanding applications.

Flat Round Air Bearings

Our Round Design frictionless motion, Flat Round air bearings works on flat, nonporous surfaces such as granite, aluminum, glass, and ceramics We offer a variety of sizes which can easily be used to customize air bearing systems. OAV Vacuum Preloaded Air Bearing provides a combination of air pressure and vacuum; essentially VPL air bearings hold it down while simultaneously lifting from surface.

OAV Roller Air Bearing

Another breakthrough innovation from OAV Air bearings in Air bearing technology. This time an Ultra Precision, Hard install, Fixed location Rotary Air Bearing to replace your conventional bearings.

Thrust Air Bearing and Bushings

Our Patent Pending OAVthrust Air Bearing is a breakthrough innovation in Air bearing technology. For the first time, an Air bearing is available that fully integrates and works on 3 way Frictionless surface. OAVThrust air bearings configurations runs on standards size shafting fix or linear motion while maximize stiff motion and ultra precise with Aerospace quality Titanium.

Air Bearing Guide

OAV Profile Rail Guides consists of the next generation OAVAir Bearing and manufactured from Aircraft Quality lightweight linear guides, Box Series, T-Series and U-series. Itis a complete offering of Air Bearing slides in a wide range of styles, sizes and unique features produced for easy retrofitting into existing applications or designing into new applications.

Flat Rectangular

We offer a line of Flat rectangular air bearing components designed to meet the non-contact requirements, low-cost, and high performance.

Ultra-Low Noise and Contactless Operation

Utilizing air lubrication and a non-contact seal, the OAV Air Bearing ensures virtually silent and frictionless motion, which is optimal for equipment where vibration and noise must be minimized. This technology results in improved longevity and performance reliability compared to traditional bearings.

High Precision for Demanding Applications

With a P4 precision rating, the OAV Air Bearing delivers accurate motion control, making it suitable for metrology instruments, semiconductor manufacturing, and aerospace testing rigs. Its robust structure supports rigorous operating conditions and strict tolerances.

FAQs of OAV Air Bearing:

Q: How is the OAV Air Bearing installed in high-precision systems?

A: The OAV Air Bearing features a flanged mount, allowing secure and straightforward installation into rotary or linear motion assemblies. Ensure proper alignment and air supply connection for optimal performance.Q: What are the advantages of using air lubrication in this bearing?

A: Air lubrication minimizes friction and wear since there is no physical contact between moving parts. This results in ultra-low noise, high-precision movement, and a significant reduction in maintenance requirements.Q: When should I consider the OAV Air Bearing for my machinery?

A: Use the OAV Air Bearing when your application demands high accuracy, low noise, and minimal vibrationsuch as in laboratory instruments, precision automation, or equipment requiring exact linear/rotary positioning.Q: Where is this air bearing distributed and supplied?

A: OAV Air Bearings are distributed, exported, imported, and supplied across the United States for a range of industrial and commercial users, ensuring broad availability and support.Q: What is the process for maintaining the OAV Air Bearing?

A: Routine maintenance involves ensuring a clean and dry air supply and monitoring environmental cleanliness to prevent particle ingress. The non-contact design reduces wear, requiring minimal maintenance overall.Q: How does the bearings structure enhance its performance?

A: A single-row air bearing with a composite retainer and non-metallic cage provides stable, precision-guided motion and compatibility with sensitive applications, while the stainless steel and aluminum body ensures durability.Q: What benefits does the zero-contact, air-lubricated system provide over traditional bearings?

A: Zero-contact air bearings eliminate mechanical wear, keeping precision intact over long cycles and significantly reducing operational noise, which is crucial for high-end research, production, and diagnostic equipment.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

Enduro Mast Guide Bearing

Price 9500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Chrome steel

Structure : Mast Guide

Lubrication Type : Other, Grease Lubricated

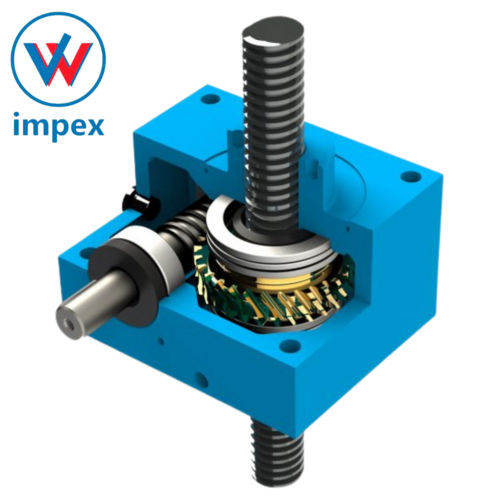

UNIMEC SCREW JACK

Price 45000 INR / Piece

Minimum Order Quantity : 45000/ Pieces

Material : Cast Iron, Other

Structure : Worm Gear Screw Jack

Lubrication Type : Other, Grease Lubrication

SILEX Limited Silicone Sheeting, Hoses And Seals

Price 8000 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Other, Platinum or Peroxide Cured Silicone Rubber

Structure : Customizable (Solid/Sheet, Hose, Seal)

Lubrication Type : Other, Nonlubricated (Silicone inherently nonstick)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry