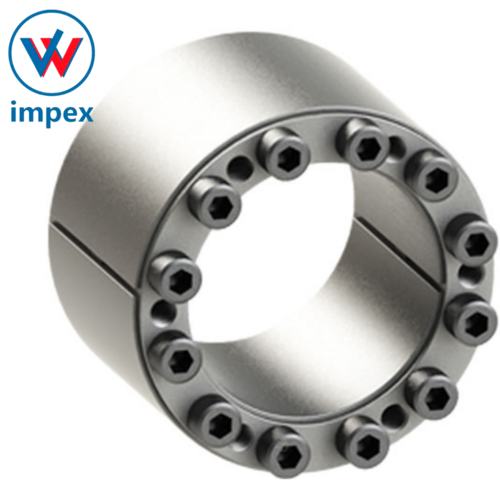

Nikki Precision Locknuts

Price 10000 INR/ Piece

Nikki Precision Locknuts Specification

- Inside Diameter

- M10 M120

- Thickness

- 6 mm 25 mm

- Precision Rating

- ISO Standard

- Bearing Type

- Locknut Bearing

- Material

- Alloy Steel

- Structure

- Precision Locknut

- Number Of Rows

- Single

- Bore Size

- M10 M120

- Outside Diameter

- Varies by Model

- Limiting Speed

- Up to 7000 rpm

- Load Capacity

- High Axial Retention

About Nikki Precision Locknuts

Competitive Edge in Precision Locking Solutions

Nikki Precision Locknuts deliver a substantial competitive advantage on the surface of critical applications. Their ISO-standard precision, ground and polished finish, and supreme corrosion resistance make them ideal for spindle locking and bearing retention across various industrial machinery. With high load capacity, easy installation, and availability in multiple sizes, Nikkis single-row structure ensures potent reliability and superior performance in demanding environments.

Sample Availability, Certifications & Seamless Delivery

Experience Nikki Precision Locknuts firsthand with available product samples and flexible payment terms. All items are certified to meet stringent ISO standards and come expertly packaged for safe transport. Enjoy the lowest price offers and prompt delivery direct from Taiwans reputable supplier networksupported by exporter, importer, and distributor expertise to ensure satisfaction on every deal.

FAQs of Nikki Precision Locknuts:

Q: How do I install Nikki Precision Locknuts for optimal performance?

A: Nikki Precision Locknuts can be installed using either a key notch or set screws, depending on the model. Follow the manufacturers guidelines to ensure proper fitment, providing secure spindle locking or bearing retention in your machinery.Q: What applications are Nikki Precision Locknuts most suitable for?

A: These locknuts are ideal for high-precision environments, including spindle locking and bearing retention in industrial machinery where fine metric threading, high axial retention, and corrosion resistance are crucial.Q: Where are Nikki Precision Locknuts manufactured and supplied from?

A: Nikki Precision Locknuts are distributed, exported, imported, and supplied from Taiwan, ensuring access to quality and precision-engineered components for the global market.Q: When can I expect delivery after placing an order for Nikki Precision Locknuts?

A: Delivery times vary depending on order volume and destination, but the seller strives for the fastest shipment with expertly handled packaging to guarantee product integrity.Q: What makes Nikki Precision Locknuts a beneficial choice compared to alternatives?

A: Their supreme surface finish, ISO-standard precision, potent load capacity, corrosion resistance, and positive reviews position them as a high-value, reliable solution for demanding industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

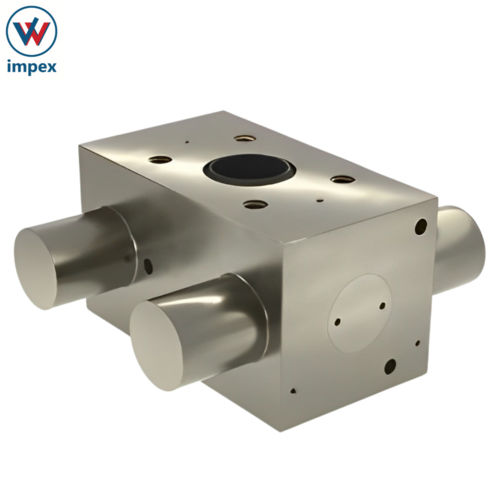

More Products in Clamping & Locking Devices Category

MAV Locking Assembly

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, High Tensile Steel (Heat Treated)

Structure : Cylindrical Locking Assembly

Lubrication Type : Other, Dry or Lightly Oiled

Limiting Speed : Up to 5000 rpm (depending on size)

ERRE.DI. Clamping Elements

Price 12500 INR / Piece

Minimum Order Quantity : 2 Pieces

Material : Other, Steel Alloy

Structure : Clamping element with segmented construction

Lubrication Type : Other, Dry / Lubricated as requested

Limiting Speed : Depends on clamping method and model

Speith Precision Locknuts

Price 15000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Alloy Steel or Stainless Steel

Structure : Locknut

Lubrication Type : Other, Thread locking compound (optional)

Limiting Speed : High, suitable for precision applications

Tollok Mechanical Locking Bushes

Price 3000 INR / Piece

Minimum Order Quantity : 5 Pieces

Material : Stainless Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry