Li-Be Bearings

Price 10000 INR/ Piece

Li-Be Bearings Specification

- Lubrication Type

- Grease / Oil

- Inside Diameter

- 1 mm to 20 mm

- Thickness

- Varies as per model

- Retainer

- Steel / Brass / Nylon

- Cage Material

- Steel / Brass / Nylon

- Precision Rating

- ABEC-1, ABEC-3, ABEC-5

- Bearing Type

- Miniature Ball Bearing

- Material

- Stainless Steel / Chrome Steel

- Structure

- Deep Groove

- Seals Type

- Open / Shielded

- Number Of Rows

- Single Row

- Bore Size

- 1 mm to 20 mm

- Outside Diameter

- 3 mm to 32 mm

- Limiting Speed

- Up to 70,000 RPM

- Load Capacity

- High

- Corrosion Resistance

- Yes

- Operating Temperature

- -20°C to +120°C

- Finish

- Polished

- Application

- Automotive, Electric Motors, Instruments, Industrial Machinery

- Packaging Type

- Box

- Feature

- Low Noise, High Speed, Long Service Life

About Li-Be Bearings

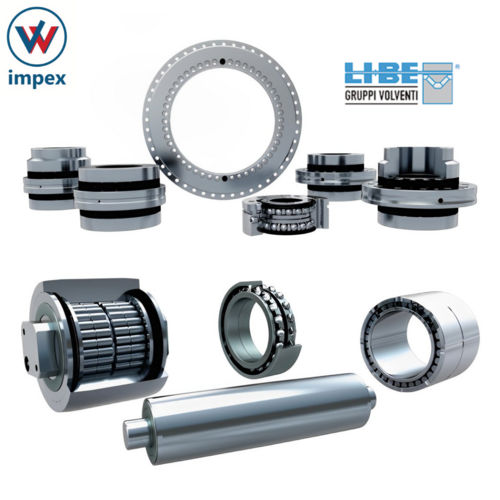

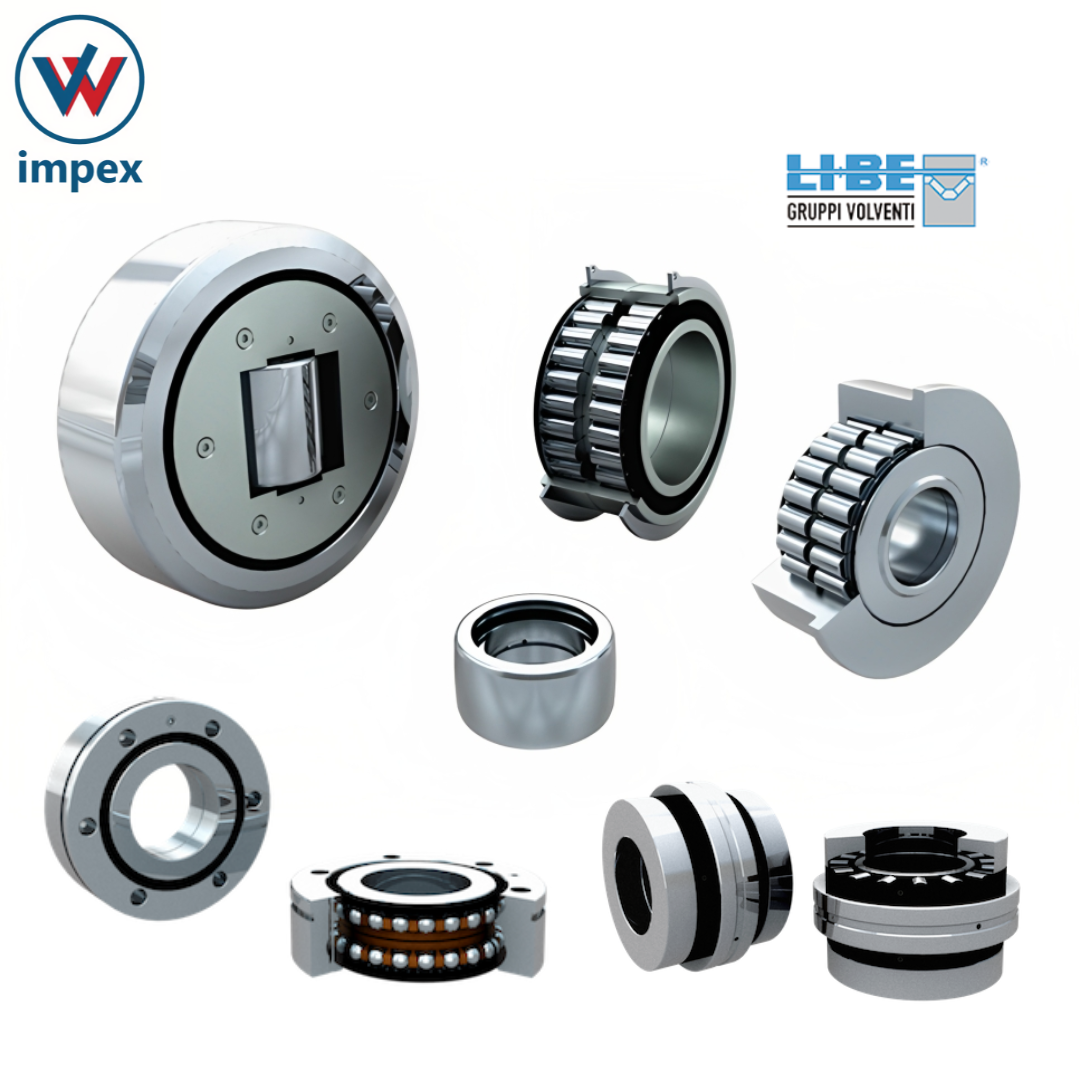

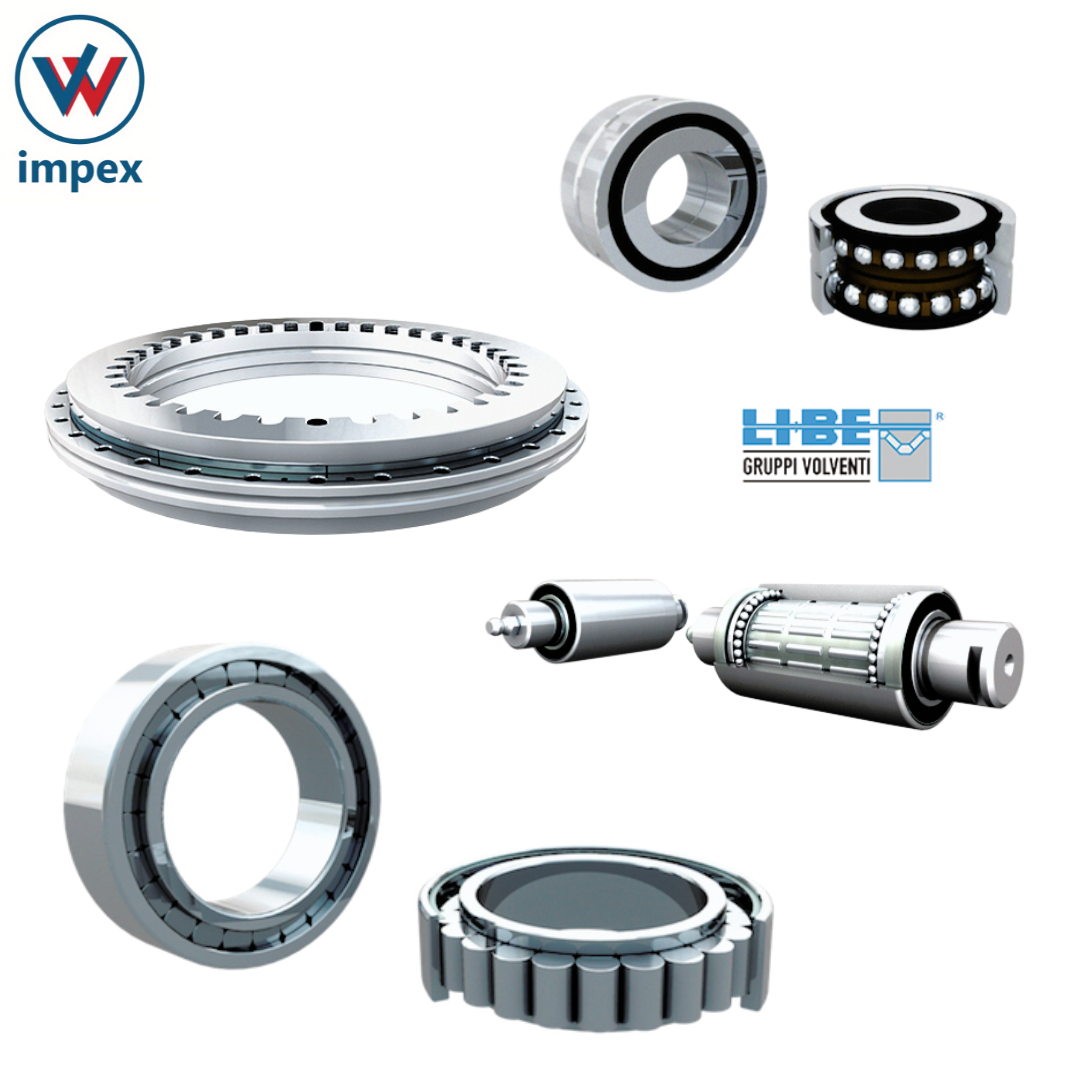

LI-BE and Linear Motion are the main sectors in which LI-BE bearings play a prestigious role on the international scene. LI-BE is one of Italy's premier manufacturers of combination bearings, full complement cylindrical roller bearings, needle roller (metric) bearings, tension leveler bearings, and others.MACHINE TOOLS

SEL series

* For recirculating ball screws

STEEL INDUSTRY

* Back-up rollers for tension levellers

* Back-up rollers for scale breakers

* For sendzimir type rolling mills

* For hot rolling

LINEAR MOTION

* Radial and combined for lift trucks

* Pulleys for chains

* Wheels for linear movement

* Guides with C-profile and double T

LI-BE produces special bearings, by dimension and execution, for different industrial applications. The range of production includes bearings, rollers and complementary articles used in the sector of internal goods handling, metallurgical machinery, painting machinery, power transmission units, rotating tables for tool machines, etc.

STEEL INDUSTRY

* MRSC 0012-0050 (Back Up Roller for Tension Leveler)

* MRS 1240-1234 (Chain Pulley Bearings)

* MCF1800, MCF2200, MCF2300, MCF2900, MCF3000 (Full Complement Cylindrical Roller Bearings)

* MRCF4900, MRCF5000 (Full Complement Cylindrical Roller Bearings)

* MCR4800, MCR4900 (Full Complement Cylindrical Roller Bearings)

* MRCL4800, MRCL4900 (Full Complement Cylindrical Roller Bearings)

* MRC119, MRCL149, MRC129, MRCL159 (Multi Row Cylindrical Roller Bearing)

* MRC139, MRCL169 (Multi Row Cylindrical Roller Bearing)

* MRF, MRF 2RS, MRF ZZ (Sealed/ Shielded Multi Row Cylindrical Roller Bearing)

* R0132- R0201 (Supporting Rollers)

* Z Mill Bearings

MACHINE TOOL INDUSTRY

* SEL/F, SEL/N (Axial Angular Contact Ball Bearings)

* SEL/Z, SEL/ZL, SEL/ZF, SEL/ZFL (Axial Cylindrical/ Needle Roller Bearings)

* SEL/Y (Axial Radial Bearings)

MATERIAL HANDLING INDUSTRY

* MR, KRES, MRG (Combination Bearings)

Superior Performance in Extreme Conditions

Li-Be Bearings excel in environments with temperatures ranging from -20C to +120C. Their robust corrosion-resistant finishes and precision ABEC ratings guarantee operational reliability and efficiency, even under strenuous workloads, making them ideal for automotive and industrial machinery.

Versatile Application and High-Speed Operation

Engineered for high-speed tasks up to 70,000 RPM, Li-Be Bearings cater to various fields such as electric motors, instruments, and automation. The deep groove, single-row structure ensures both stability and elevated load capacity, further supported by optimized lubrication and retainer materials.

Packaging and Distribution

Li-Be Bearings are distributed, exported, and supplied globally-including Italy-packed securely in boxes to safeguard against transit damage. Traders and importers benefit from flexible sealing, bore size, and outside diameter options, tailored to unique usage requirements.

FAQ's of Li-Be Bearings:

Q: How should Li-Be Bearings be installed in automotive or industrial machinery?

A: Li-Be Bearings are designed for easy integration into automotive, electric motors, and industrial equipment. Installation should be performed by trained personnel who ensure proper alignment, lubrication, and seating, as per the manufacturer's recommendations for optimal performance and long service life.Q: What bore size and outside diameter options are available for Li-Be Bearings?

A: Li-Be miniature ball bearings are offered with bore sizes ranging from 1 mm to 20 mm and outside diameters between 3 mm to 32 mm, accommodating a wide variety of equipment and application needs.Q: Where can Li-Be Bearings be sourced for distribution in Italy?

A: Li-Be Bearings are available through authorized distributors, exporters, importers, and suppliers with global outreach, including dedicated channels for traders in Italy. Contact your local distributor for product availability and technical support.Q: When is it necessary to choose shielded versus open seals for Li-Be Bearings?

A: Shielded bearings are recommended when protection against dust or moisture is required, prolonging the bearing's life and ensuring quieter performance. Open bearings suit environments where regular maintenance and inspection are feasible or where minimal sealing suffices.Q: What process ensures the corrosion resistance of Li-Be Bearings?

A: Li-Be Bearings achieve corrosion resistance through the use of premium stainless steel or chrome steel materials and a polished finish. This process enables them to resist environmental degradation in demanding industrial and automotive settings.Q: How do Li-Be Bearings support high speed and low noise operation?

A: With deep groove engineering, precision ABEC ratings, and selected lubrication types (grease or oil), Li-Be Bearings reduce operational friction and vibration. This design ensures consistent high-speed performance up to 70,000 RPM while maintaining quiet running characteristics.Q: What are the benefits of using Li-Be Bearings in electric motors and sensitive instruments?

A: Li-Be Bearings provide stability, high load capacity, and low noise levels, crucial for electric motors and precision instruments. Their high-speed capability, single row deep groove configuration, and durable construction result in longer service intervals and reliable operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Bearings Category

Extended Inner Ring Bearings

Price 1000-10000 INR

Minimum Order Quantity : 5 Pieces

Material : Chrome steel

AEGIS SGR Bearing Protection Ring

Price 75000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Other, Special conductive microfibers, Aluminum housing

NTN Sensor Bearing

Price 4000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbon Steel

Color : Black And Silver

Size : Different Available

Warranty : Yes

Tandem Thrust Bearings

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Stainless Steel

Color : silver

Size : Different Available

Warranty : Yes

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry