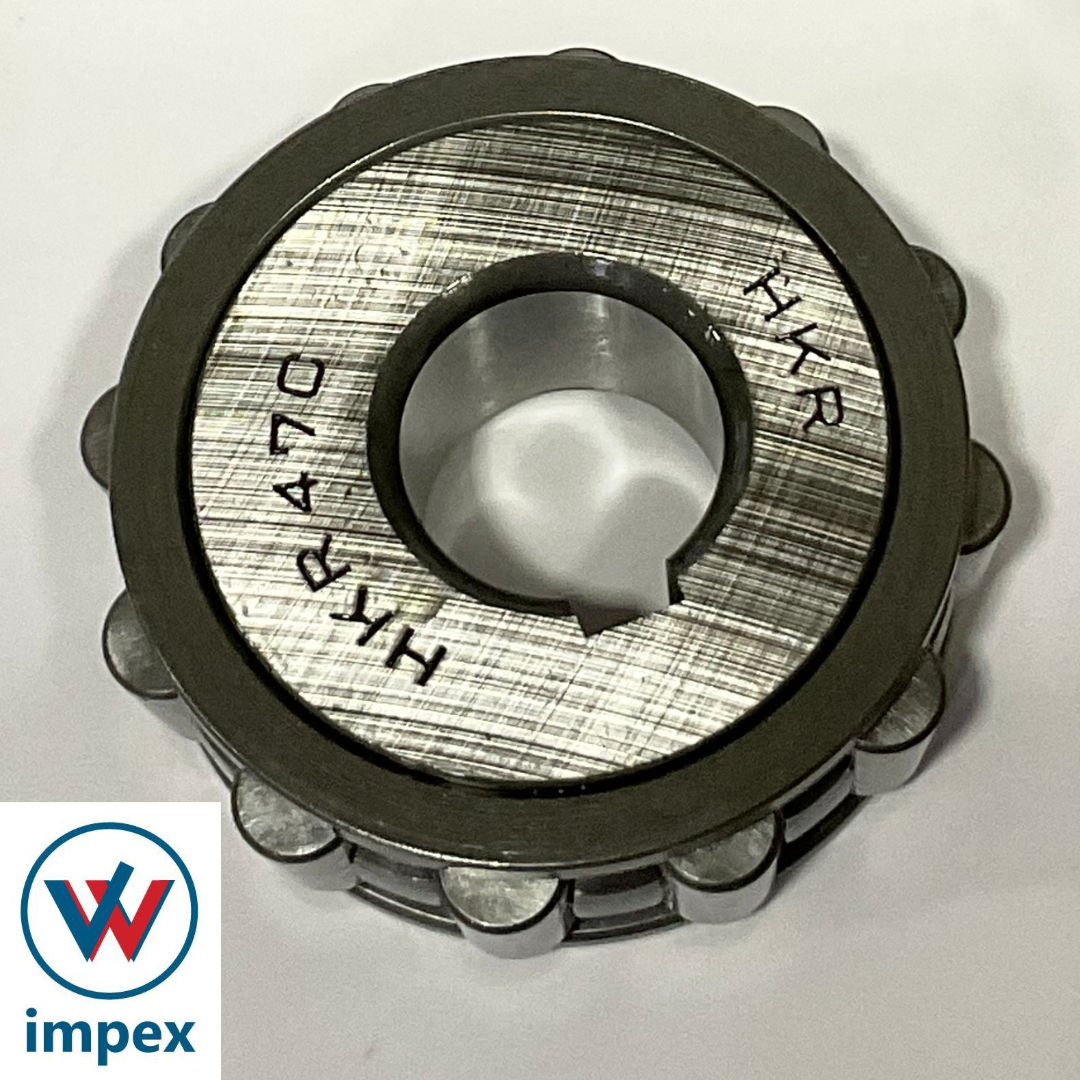

HKR Eccentric Bearings

Price 7500 INR/ Piece

HKR Eccentric Bearings Specification

- Precision Rating

- P0, P6, P5, P4

- Cage Material

- Steel

- Thickness

- 21 mm

- Inside Diameter

- 17 mm

- Retainer

- Available

- Lubrication Type

- Grease

- Bearing Type

- Eccentric Bearing

- Material

- Chrome steel

- Structure

- Eccentric

- Seals Type

- Open / Shielded

- Number Of Rows

- Single Row

- Bore Size

- 17 mm

- Outside Diameter

- 40 mm

- Limiting Speed

- 7000 rpm

- Load Capacity

- High Load Capacity

- Surface Finish

- Polished

- Corrosion Resistance

- Yes

- Shape

- Cylindrical

- Feature

- Low Noise, Durable, Easy Installation

- Weight

- Approx. 220 grams

- Application

- Textile Machinery, Automation Equipment, Robotics

- Temperature Range

- -20°C to +120°C

HKR Eccentric Bearings Trade Information

- Minimum Order Quantity

- 1 Piece

- Certifications

- Yes

About HKR Eccentric Bearings

We have earned huge appreciation in this domain, our firm is renowned as a leading supplier and exporter of high quality assortment of HKR Eccentric Bearings. These bearings are sourced by our skilled manpower from the trusted vendors, who manufacture these bearings by making use of unmatched quality materials and advanced technologies. Our stringently testified HKR Eccentric Bearings are ideally used in heavy duty machinery for lowering the friction between moving parts.

Features:

- Improvise functionality

- Rigid and corrosion proof texture

- Dimensional precision

| Type | Roller Bearing |

| Packaging Type | single |

| Quantity Per Pack | One |

| Seal Type | No |

| Brand | HKR |

| Bore Size | 30 - 100 mm |

| Outside Diameter | 40 - 150 mm |

| Application | Machines |

Robust Structure and Material Quality

HKR Eccentric Bearings are manufactured using chrome steel with a polished surface finish, ensuring resistance to corrosion and delivering excellent mechanical strength. The cylindrical shape and single row eccentric structure provide stability and efficiency in various high-speed industrial processes.

Versatile Applications and Easy Installation

With a bore size of 17mm and an outside diameter of 40mm, these bearings are ideal for textile machinery, robotics, and automation equipment. The bearings are engineered for straightforward installation, enabling quicker maintenance and reducing downtime in industrial operations.

High Precision and Performance

Offering precision ratings from P0 to P4 and a limiting speed of up to 7000 rpm, HKR bearings guarantee smooth operation under high load conditions. The combination of a steel cage, durable retainer, and grease lubrication type further enhances reliability and extends service life.

FAQs of HKR Eccentric Bearings:

Q: How are HKR Eccentric Bearings installed in textile machinery and automation equipment?

A: HKR Eccentric Bearings are designed for easy installation, featuring a cylindrical shape and single row construction. Their standard dimensions (17mm bore, 40mm outside diameter) ensure compatibility with common industrial housings, simplifying mounting and replacement processes.Q: What benefits do HKR Eccentric Bearings offer for robotics and automated systems?

A: These bearings provide high load capacity, low noise operation, and excellent durability, which are essential for smooth functioning and extended lifespan in robotics and automated systems. Their corrosion-resistant chrome steel material also ensures reliable performance in demanding environments.Q: When should I choose shielded versus open seal types for HKR Eccentric Bearings?

A: Shielded bearings are recommended in environments where dust or contaminants might interfere with operation, providing extra protection and longer maintenance intervals. Open bearings are suitable for applications requiring lower friction and are easier to inspect and lubricate.Q: Where can HKR Eccentric Bearings be sourced in India?

A: HKR Eccentric Bearings are available through authorized distributors, exporters, importers, suppliers, and traders across India. Buyers can contact these channels to acquire genuine bearings suitable for industrial use.Q: What is the typical process for lubricating HKR Eccentric Bearings?

A: The bearings are engineered for grease lubrication. Regular maintenance involves applying high-quality grease between the bearing surfaces to minimize friction and wear, aiding in consistent high-speed operation and lengthening service life.Q: What usage conditions are ideal for HKR Eccentric Bearings?

A: These bearings perform optimally in applications involving temperatures ranging from -20C to +120C, making them suitable for various industrial machinery. Their high precision ratings ensure they can handle demanding tasks with minimum noise and vibration.Q: How does the eccentric structure benefit the bearings function?

A: The eccentric design allows for precise adjustment and compensation for alignment errors in machinery, enhancing operational accuracy and reducing stress on machine components over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Eccentric Bearings Category

HISX Cyclo Drive Bearing

Price 4500 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : Industrial

Color : silver

Warranty : Yes

NTN Eccentric Bearing

Price 5500 INR / Piece

Minimum Order Quantity : 2 Pieces

Usage : Industrial

Color : Brown

Material : Stainless Steel

Warranty : Yes

Koyo Eccentric Bearings

Price 6500 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbon Steel

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry