Call: 08045801215

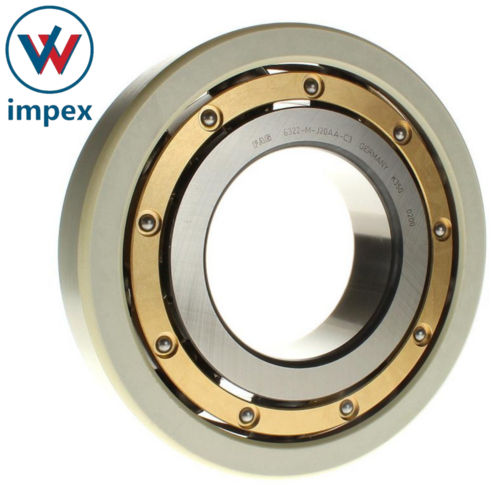

FAG INSULATED BEARING

Price 45000 INR/ Piece

MOQ : 1 Piece

FAG INSULATED BEARING Specification

- Thickness

- 7 mm to 60 mm

- Weight

- 0.30 kg to 18 kg (Depending on model)

- Material

- High Grade Steel with Insulated Coating

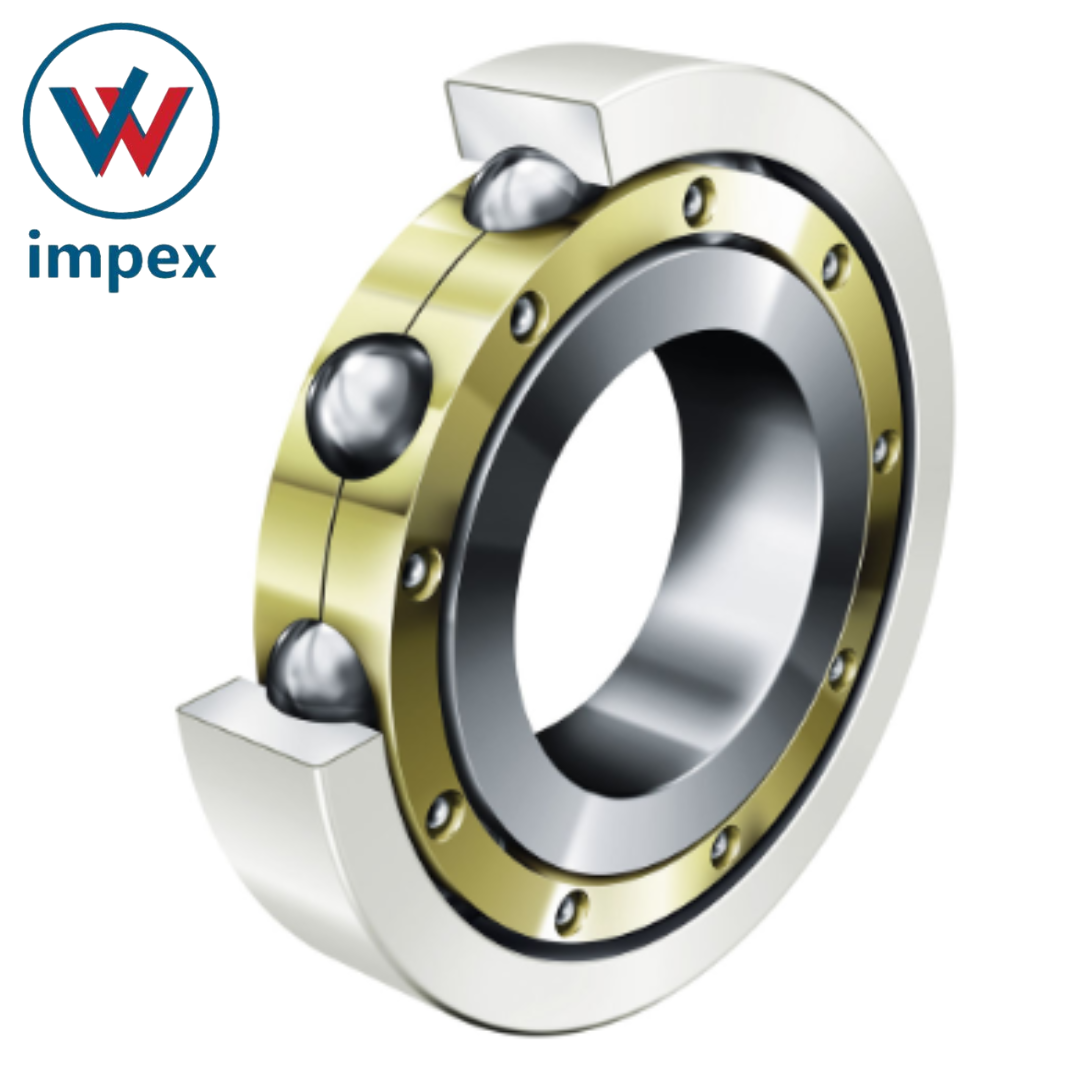

- Ball Bearing Type

- Deep Groove Ball Bearing

- Roller Bearing Type

- Cylindrical Roller Bearing

- Bushes Type

- Insulated Type

- Structure

- Single Row, Open / Sealed Option

- Seals Type

- Metal Shield / Rubber Seal / Open Type

- Number Of Rows

- Single or Double Row

- Bore Size

- 25 mm to 200 mm (Various sizes available)

- Outside Diameter

- 52 mm to 340 mm

- Limiting Speed

- Up to 9000 RPM (Varies by size)

- Load Capacity

- Dynamic up to 325 kN (Varies by model)

- Inner Diameter

- 25 mm to 200 mm

- ISO Certification

- ISO 9001:2015

- Temperature Range

- -40°C to +150°C

- Corrosion Resistance

- Enhanced due to Insulated Layer

- Mounting

- Universal Mounting

- Noise Level

- Low Noise Design

- Voltage Withstand Capability

- Up to 1000 V

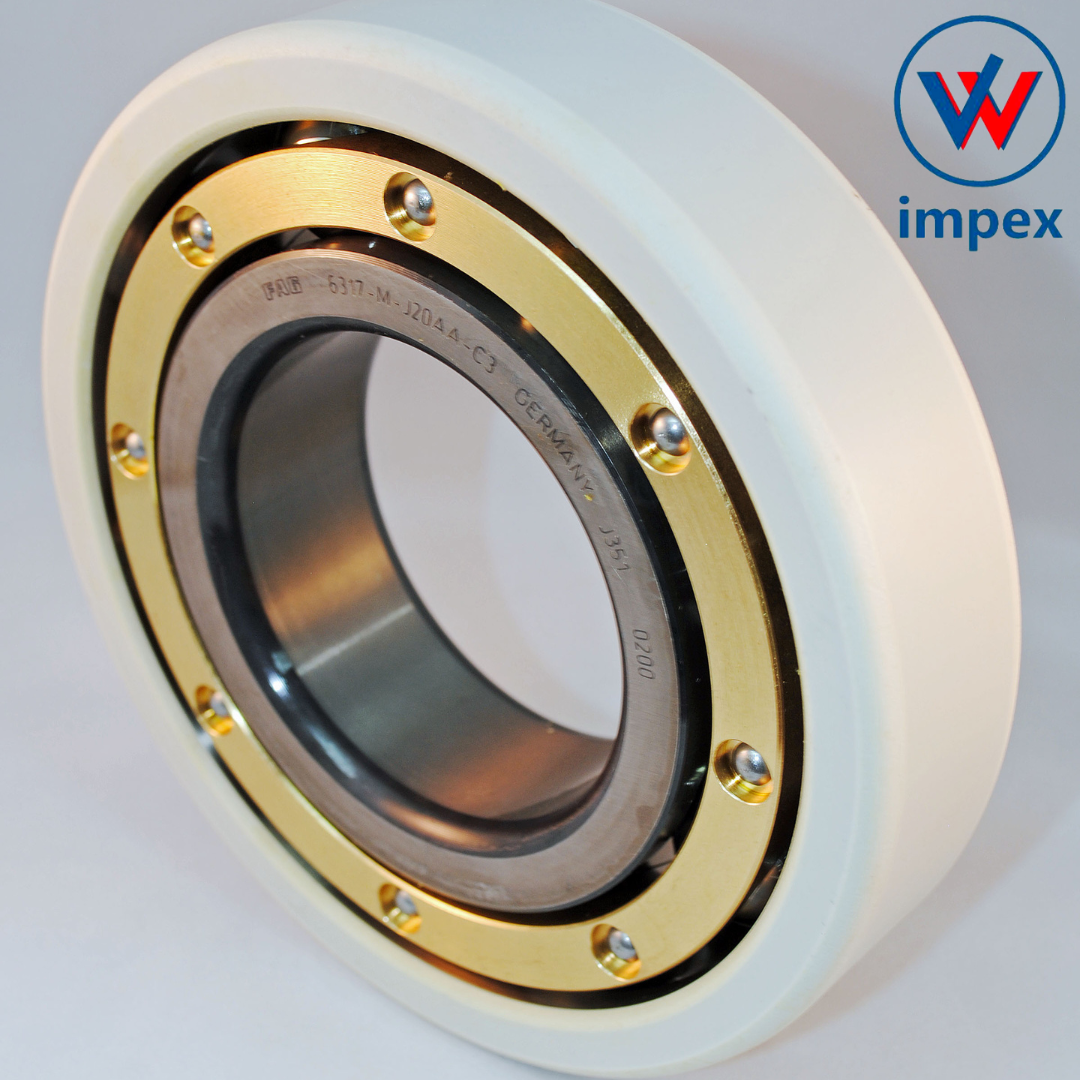

- Insulation Type

- Plasma-Sprayed Ceramic Coating on Outer or Inner Ring

- Precision Rating

- P0, P5, P6

- Surface Finish

- Ground and Polished

- Life Expectancy

- Long Service Life under Standard Operating Conditions

- Usage/Application

- Electric Motors, Generators, Traction Motors, Industrial Equipment

About FAG INSULATED BEARING

To prevent such damage, the FAG offers current-insulated bearings:

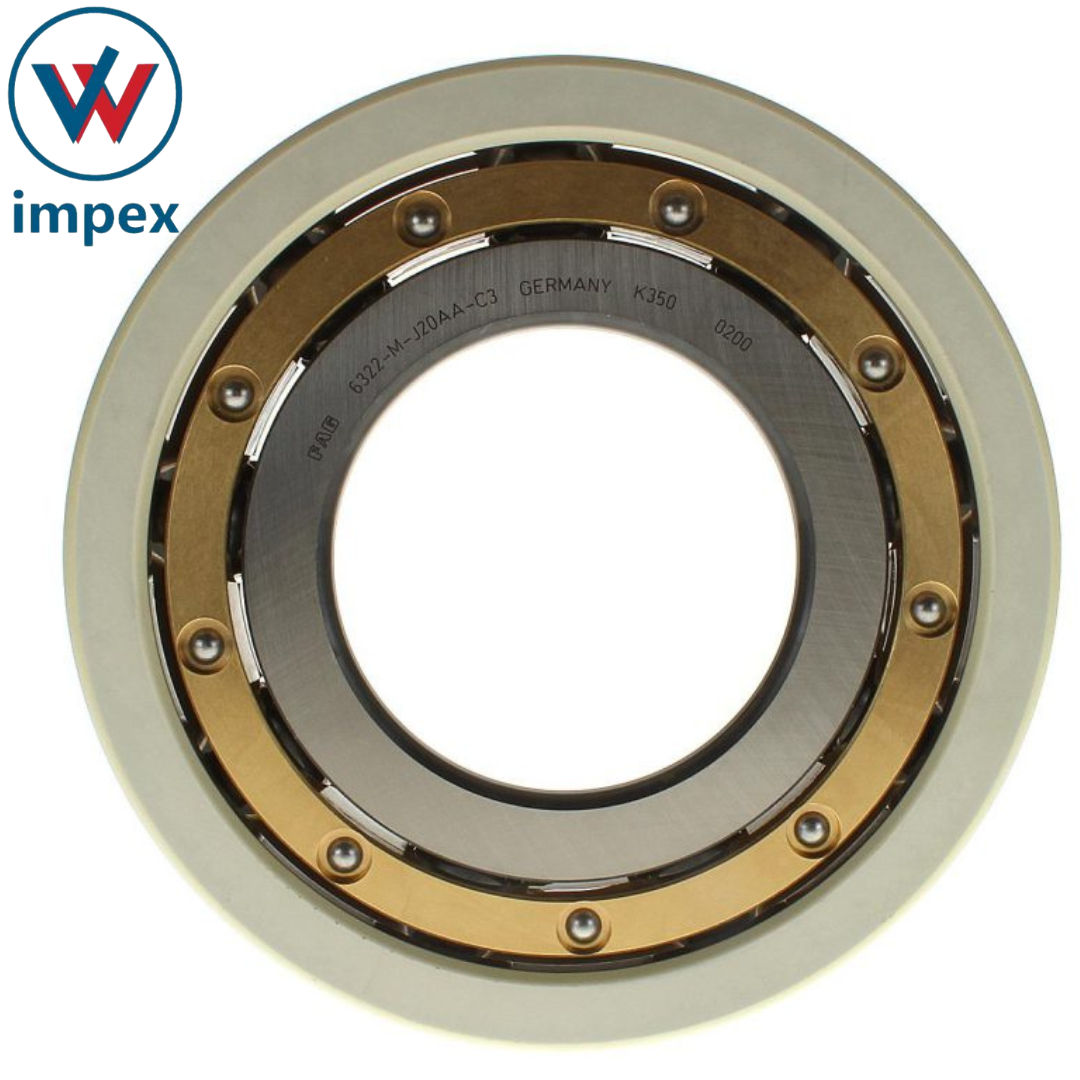

6220-2RSR-J20AA-C3:

Cylindrical roller bearings with a coated outer ring and radial clearance C4.

6330-J20C:

- Current-insulated bearings and hybrid bearings

- Current-insulated bearings have either an outer ring (J20 A, J20 AA, J20B) or an inner ring (J20C) that is insulated with thin ceramic coating

- Different coating types are available for optimum functional performance

- Disruptive voltage 500 VDC 1000 VDC 1000 VDC 1000 VDC

- Environment dry dry dry/damp dry/damp

- Coating thickness 200m ,200 m ,200 m

- Current-insulated bearings have the same dimensions and load carrying capacities as those without insulation, which makes them perfectly interchangeable

- The most common type of insulation used in electric motor applications is the J20AA coating. It offers excellent protection against passage of electrical current, even in damp atmospheres

- Bearings with ceramic coating are available with seals also

- Bearings with J20C coating on the inner ring are used in special applications as well as applications where the outer ring rotates. Z shields can be used as well

6220-2RSR-J20AA-C3:

- Deep groove ball bearing with a coated outer ring, with seals on both sides and radial clearance C3.

Cylindrical roller bearings with a coated outer ring and radial clearance C4.

6330-J20C:

- Deep groove ball bearings with a coated inner ring

Advanced Electrical Insulation

The plasma-sprayed ceramic coating on the ring effectively insulates against stray currents, preventing electrical damage and extending bearing lifespan. This allows the bearings to withstand voltages up to 1000 V, making them an ideal choice for applications with high risk of electrical discharge, such as electric motors and generators.

Engineered for Reliability and Longevity

FAG insulated bearings are manufactured using high-grade steel with smooth ground and polished finishes. Their robust structure, available in both deep groove ball bearing and cylindrical roller bearing types, ensures long service life under standard operating conditions. Enhanced corrosion resistance and universal mounting offer flexibility for diverse industrial setups.

Certified Quality for Industrial Applications

These bearings are ISO 9001:2015 certified, guaranteeing consistent quality and performance. Available in various dimensions, load capacities, and seal types, they meet the demands of electric motors, traction motors, and other industrial equipment across India. Distributors, exporters, importers, suppliers, and traders benefit from versatile solutions tailored to numerous industries.

FAQs of FAG INSULATED BEARING:

Q: How do the plasma-sprayed ceramic coating bearings prevent electrical damage?

A: The ceramic coating acts as an insulating barrier on the bearings outer or inner ring, preventing stray electrical currents from passing through the bearing. This safeguards the bearings internal components from electrical erosion and extends operational life in electric motors or generators.Q: What types of equipment commonly use these insulated bearings?

A: FAG insulated bearings are well-suited for electric motors, generators, traction motors, and other industrial machines where electrical insulation is necessary. They are also beneficial in applications prone to shaft currents and electrical discharge.Q: When should one opt for sealed versus open bearing designs?

A: Sealed bearingseither with metal shields or rubber sealsare recommended when protection against contaminants and lubrication retention is required. Open designs are ideal when maintenance access is easy and operating environments are clean.Q: Where can these insulated bearings be sourced in India?

A: These bearings are available through authorized distributors, exporters, suppliers, and traders across India who specialize in supplying high-performance industrial bearings for both domestic and export markets.Q: What is the process for mounting these bearings onto equipment?

A: FAG insulated bearings feature universal mounting options, allowing them to be installed using standard fitting procedures. Their precision ground and polished surfaces facilitate easy, accurate alignment for single or double row structures.Q: How does the insulated layer enhance corrosion resistance?

A: The plasma-sprayed ceramic insulation not only serves as an electrical barrier but also protects against surface corrosion, helping maintain optimal performance in challenging industrial environments.Q: What are the life expectancy and maintenance requirements for these bearings?

A: FAG insulated bearings are designed for long service life under standard conditions, with low noise and minimal maintenance requirements. Using proper installation and regular inspection helps maximize operational longevity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Insulated Bearings Category

SKF Insulated Bearing

Price 50000 INR / Piece

Minimum Order Quantity : 1 Piece

Ball Bearing Type : Other, Deep Groove Ball Bearing

Number Of Rows : Other, 1

NKE Insulated Bearing

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Ball Bearing Type : Other

Usage : INDUSTRIAL

Product Type : INSULATED BALL BEARING

Number Of Rows : Other

AKN Bearings Germany

Price 25000 INR / Piece

Minimum Order Quantity : 1 Piece

Usage : INSULATED BEARING

Product Type : All Type Of Bearings

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry