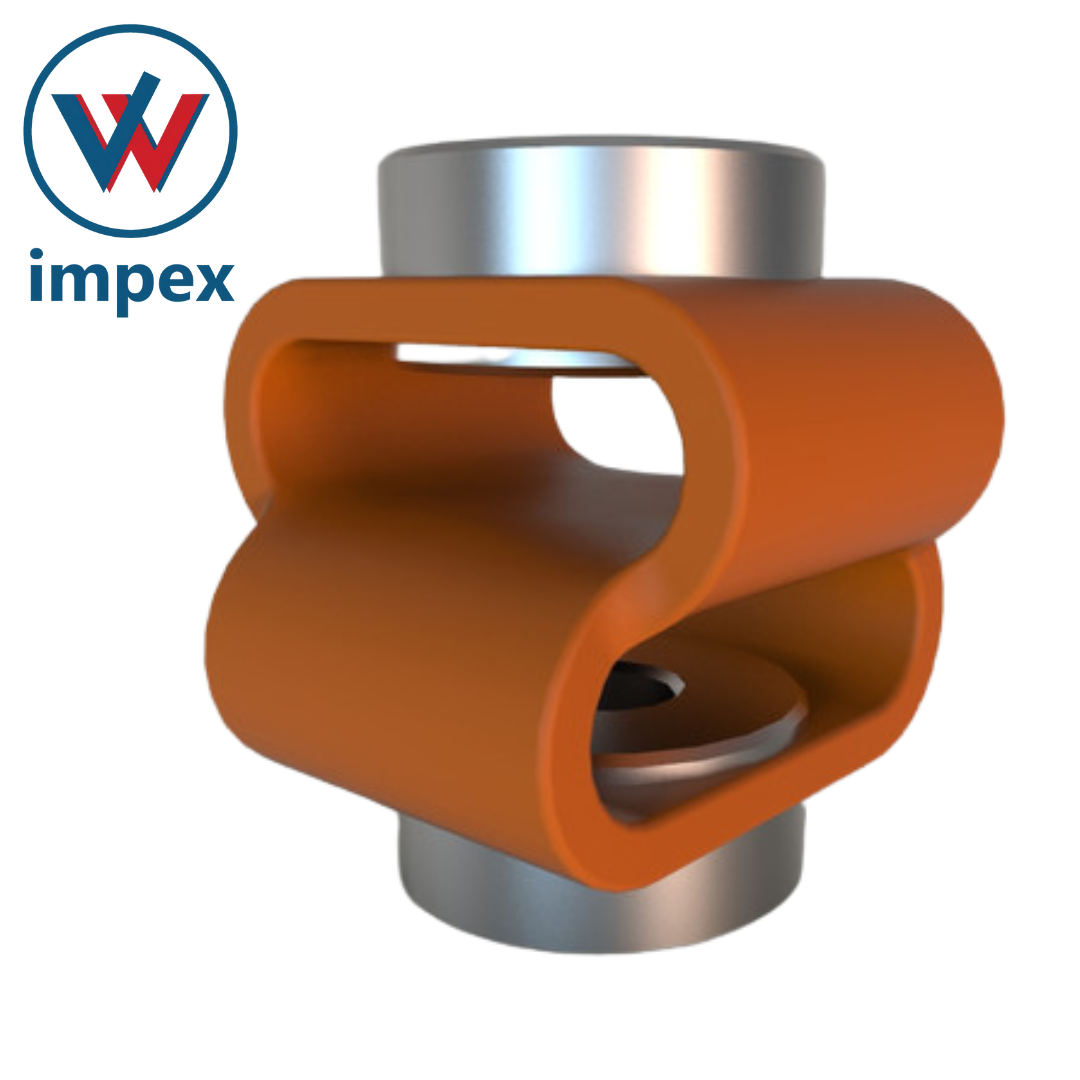

Paguflex Double Loop Coupling

Price 6500 INR/ Piece

Paguflex Double Loop Coupling Specification

- Inside Diameter

- 6 mm to 28 mm

- Thickness

- Approx. 8 mm - 20 mm (varies by model)

- Precision Rating

- High Precision

- Lubrication Type

- Dry (Maintenance Free)

- Bearing Type

- Flexible Shaft Coupling (No bearings)

- Material

- Spring Steel (Loops), Aluminum Alloy (Hubs)

- Structure

- Double Loop Coupling

- Number Of Rows

- Single Row

- Bore Size

- 6 mm to 28 mm

- Outside Diameter

- 16 mm to 80 mm

- Limiting Speed

- Up to 12,000 rpm

- Load Capacity

- Variable, depends on shaft size and application

About Paguflex Double Loop Coupling

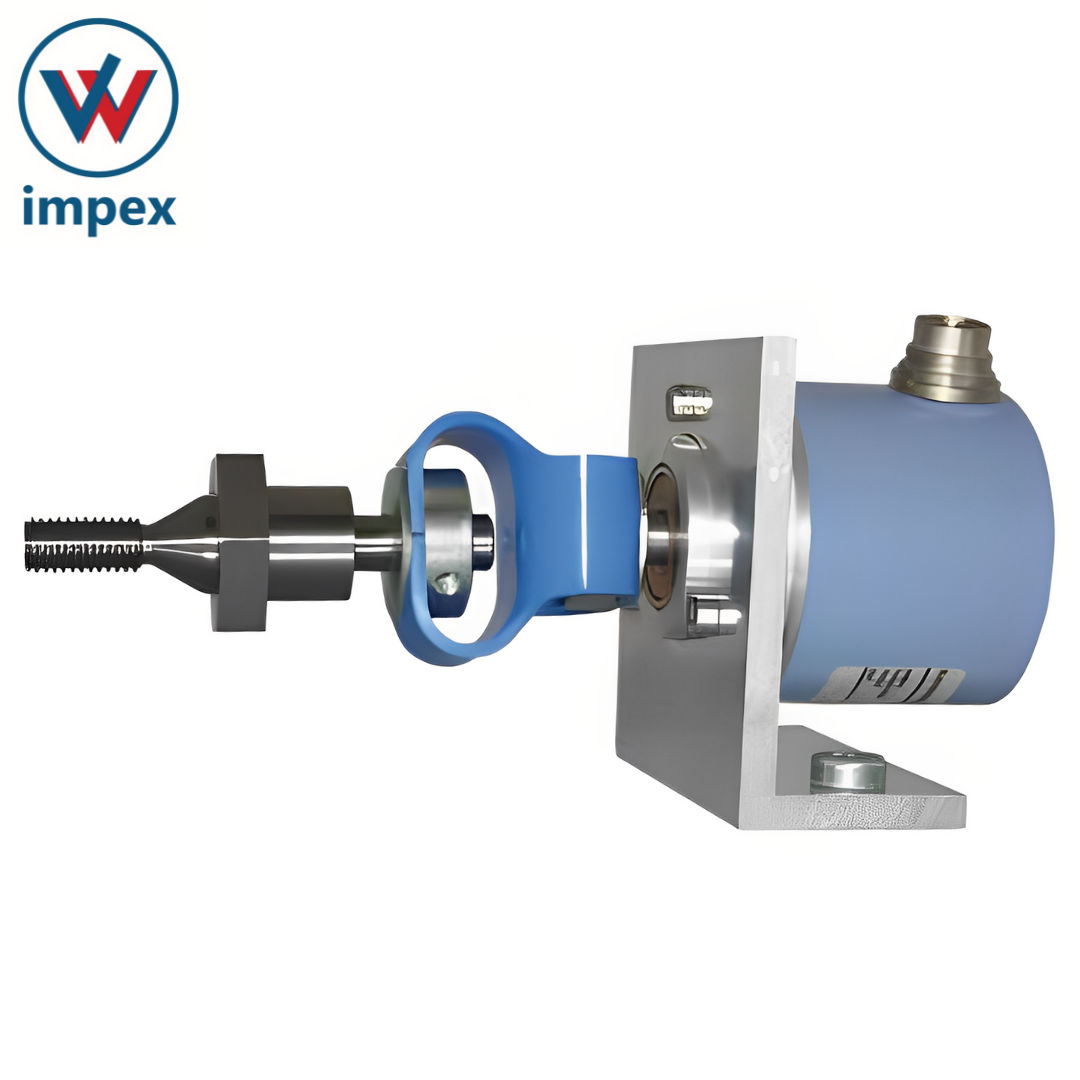

PAGUFLEX PLUS shaft couplings... the sure, uncomplicated, economical solution, if angled, radial and/or axially displaced drive shafts are to be frictionally connected.

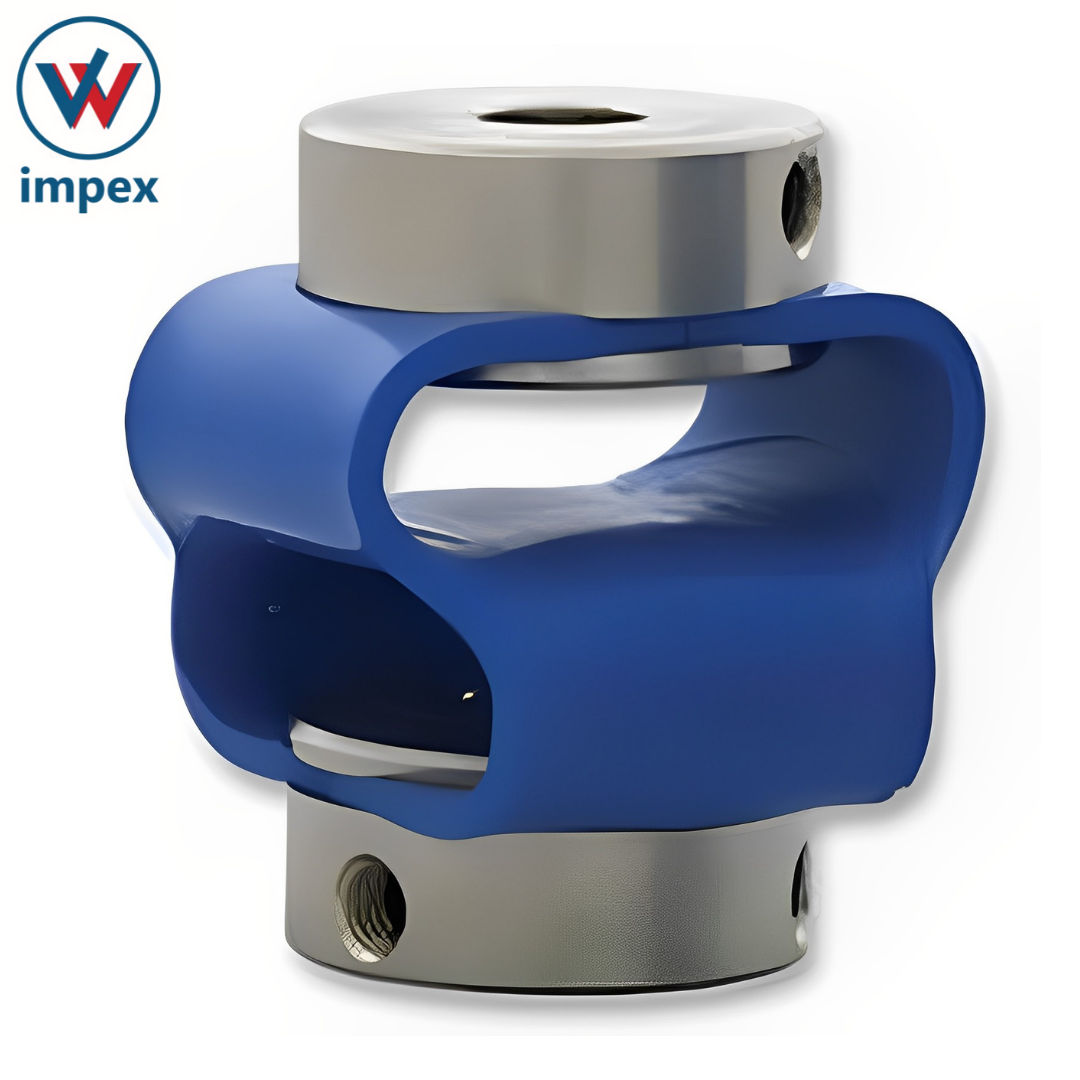

NEW: Double loop-shaped, thermoplastic compensating coupling element made from HYTREL, a Thermoplastic Ether Ester Elastomer (TEEE) from DuPont.

Owing to the high reverse bending strength of the flexible material and the cardan-like shaping of the power transmitter, this development is the ingenious, technical solution for shaft displacement problems in motive power engineering, and in measurement and control techniques.

Recommendations for our products are for the design of: shaft-angle encoders, counting mechanisms, tachogenerators, servo valves, elevating tables, feeding drives, pumps, compressors and ventilators, kitchen equipment, office systems, textile machines and for numerous applications in the automobile and aircraft industries.

The one-piece coupling is frictionless, wear less, and silent, and works without any troubling effects (i.e., without troubling structure-borne sounds).

Thus, in changes of direction or rotation, or during torque fluctuations with load direction reversal, PAGUFLEX PLUS enables play-free and shock-free power transmission, together with effective vibration damping and sound insulation.

In numerous technical applications, the material HYTREL has been successfully substituted not only for established thermoplastics, but also for elastomers. It combines ideally the advantages of both materials, and is therefore the best innovation for flexible shaft couplings.

It enables the opening up of new areas of applications for extremely low and high temperatures. Also, in association with media in which, owing to their sensitivity, elastic elements have shown themselves to be of 'limited use'. Further applications are those in which up to now the reverse bending strength of the material has set, narrow limits with regard to mechanical fatigue loading. In these, PAGUFLEX PLUS is now the solution.

The high flexibility of the thermoplastic coupling element effectively lightens the burden on the shaft bearings of motors and machines, even in circumstances of large radial and angular alignment errors. With the help of PAGUFLEX PLUS, the bearings run quieter, warm-up less, and achieve longer durability, thus lengthening service life.

PAGUFLEX PLUS - plus points :

- high torsional rigidity with optimal beeding and traction or thrust flexibility

- ingeniously simple constructional principle

- one piece design - without play, friction, wear and structure

vibrations

- simple fitting, no extra machining of the shaft journals

- minimum fitting volume, radially and axially

- coupling can be used as a universal joint for large or intermittent bending angles of the shaft.

- elastic element made of HYTREL (Thermoplastic Ether Ester Elastomer, TEEE);

Enabling:

- high operational reliability in the temperature range between -40*C und +100*C

- outstanding chemical resistance to acids, alkalis, solvents, oils, gases, ozone

- high tear propagation resistance, high low- temperature flexibility, high abrasion resistance and reverse bending strength

- Insulation from heat, structure-borne noise and leakage currents

- damping of vibration and shock

- relieves the motor/machine shaft bearings of lateral and axial forces

- steel bosses with corrosion-protected, galvanized surface

| Condition | New |

| Finish | Galvanized, Mirror Polished |

| Features | steel |

| Usage/Application | any |

| Bore Diameter | 10 |

Exceptional Flexibility and Precision

The Paguflex Double Loop Coupling stands out for its ability to absorb multiple types of misalignment-axial, radial, and angular-making it ideal for precision-driven operations. Its spring steel loops and aluminum alloy hubs provide both strength and flexibility, ensuring reliable performance at speeds up to 12,000 rpm without sacrificing precision. This makes it a top choice for engineers seeking consistent motion control.

Robust Construction and Finish

Constructed with high-grade spring steel loops and anodized aluminum alloy hubs, the coupling guarantees durability and longevity. A choice between clamp or set screw mounting enhances versatility for varied installation needs. Metallic grey steel loops and silver finished hubs add a professional appearance. The finish is both robust and corrosion-resistant, supporting applications in varied industrial environments.

Versatile Application and User Benefits

Compatible with bore sizes from 6 mm to 28 mm, the coupling adapts seamlessly to a wide range of shaft sizes and applications in automation, robotics, and precision machinery. Its dry, maintenance-free design minimizes operational downtimes, while its RoHS compliance assures safe, responsible use. As a distributor, exporter, importer, supplier, and trader in Germany, we ensure prompt delivery and expert support.

FAQ's of Paguflex Double Loop Coupling:

Q: How does the Paguflex Double Loop Coupling accommodate shaft misalignment?

A: The Paguflex Double Loop Coupling is designed to compensate for axial, radial, and angular misalignments. Its flexible double loop structure allows shafts to move without transferring undue stress to connected equipment, ensuring smooth and precise operation even when alignment is not perfect.Q: What is the process for selecting the correct coupling size for my application?

A: Selection involves matching the shaft diameter (6 mm to 28 mm), required torque (0.5 Nm - 50 Nm), operating speed (up to 12,000 rpm), and installation preferences (clamp or set screw). Consider the application's specific misalignment and load conditions to ensure optimal performance. Our team provides guidance to help you choose the right model.Q: When should I use this flexible coupling instead of a rigid coupling?

A: The flexible double loop coupling should be used when your application requires compensation for misalignments or needs to minimize vibration and shock loads. It is especially ideal for precise systems such as servo motors, stepper motors, encoders, and precision drives, where maintaining alignment can be challenging.Q: Where can the Paguflex Double Loop Coupling be installed?

A: This coupling is suitable for installation in precision automation machinery, robotics, conveyors, and various motion control systems. Its robust construction and temperature tolerance from -20C to +80C make it adaptable to typical industrial and laboratory environments.Q: What are the key benefits of using this coupling in high-speed or precision applications?

A: Its high precision rating ensures minimal backlash and accurate torque transfer at speeds up to 12,000 rpm. The maintenance-free, dry operation and high-strength materials deliver exceptional reliability, improving overall equipment performance with minimal intervention.Q: Is the coupling compliant with environmental or safety standards?

A: Yes, the Paguflex Double Loop Coupling is RoHS compliant, which means it meets rigorous environmental safety standards, restricting the use of hazardous substances in its materials.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Couplings & Gears Category

Rexnord Coupling And Gears

Price 5000 INR / Piece

Minimum Order Quantity : 1 Piece

Precision Rating : ISO Standard

Structure : Gear Coupling

Material : Other, Alloy Steel

Lubrication Type : Other, Grease Lubrication

Neugart Planetary Gearbox

Price 35000 INR / Piece

Minimum Order Quantity : 1 Piece

Precision Rating : ISO Class 6

Structure : Planetary Gearbox

Material : Other, Highgrade Alloy Steel

Lubrication Type : Other, Permanent grease lubrication

Double Loop Flex P Coupling Huco

Price 3500 INR / Piece

Minimum Order Quantity : 2 Pieces

Precision Rating : High Precision

Structure : Double Loop Flex Coupling

Material : Other, Aluminum Alloy & Polyamide Loop

Lubrication Type : Other, Maintenance Free / Dry

TB Woods Jaw Couplings

Price 5000

Minimum Order Quantity : 1 Piece

Precision Rating : Standard Industrial

Structure : Jaw Coupling

Material : Other, Cast Iron or Steel (Coupling); Nitrile Rubber (Spider)

Lubrication Type : Other, No lubrication required (maintenancefree)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry